Movable integrated gas station

A gas filling station and gas filling machine technology, which is applied in the field of gas filling stations, can solve the problems of large area of gas filling stations, and achieve the effects of facilitating gas filling operations, reducing station construction area, and simplifying station construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

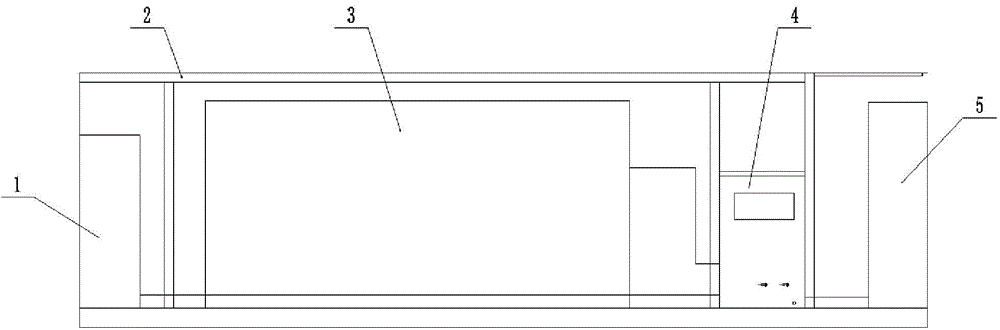

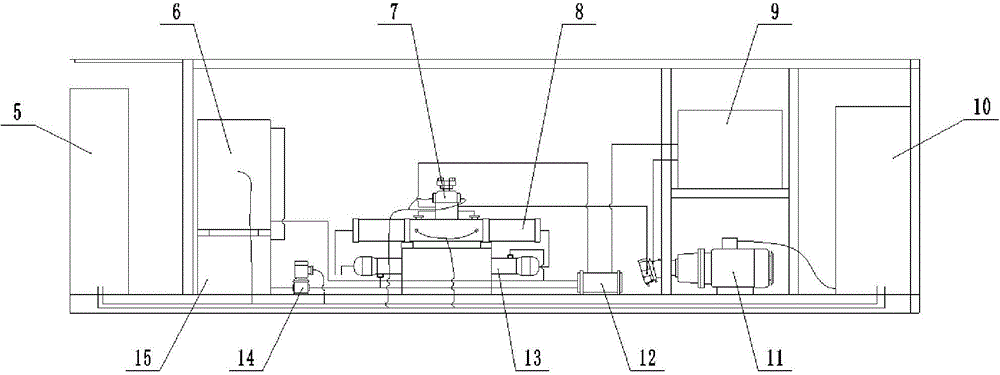

[0010] The following examples refer to figure 1 and figure 2 .

[0011] The mobile integrated gas filling station of the present invention is divided into three parts, the first half is the filling machine 5, the second half is the unloading column 1 and the electric control equipment 10; System 4. The booster equipment is a hydraulically driven compressor, which includes an air cooler 6, a reversing mechanism 7, an air compressor cylinder 8, a hydraulic oil tank 9, a power system 11, an oil cooler 12, a heat exchanger 13, a cooling water pump 14 and cooling Liquid tank 15.

[0012] The electric control equipment 10 leads from the bottom of the pry body 2 to the pressurization equipment, the power line is connected to the power system 11, and the power line is connected to the air discharge column 1, the gas dispenser 5, and the air cooling system. The device 6 and the cooling water pump 14 are connected, and the signal line is connected with the air discharge column 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com