An energy-saving compression refrigeration method

A compression refrigeration and compressor technology, which is applied in the direction of refrigerators, compressors, refrigeration components, etc., to achieve the effects of reducing the risk of liquid, reducing energy consumption, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

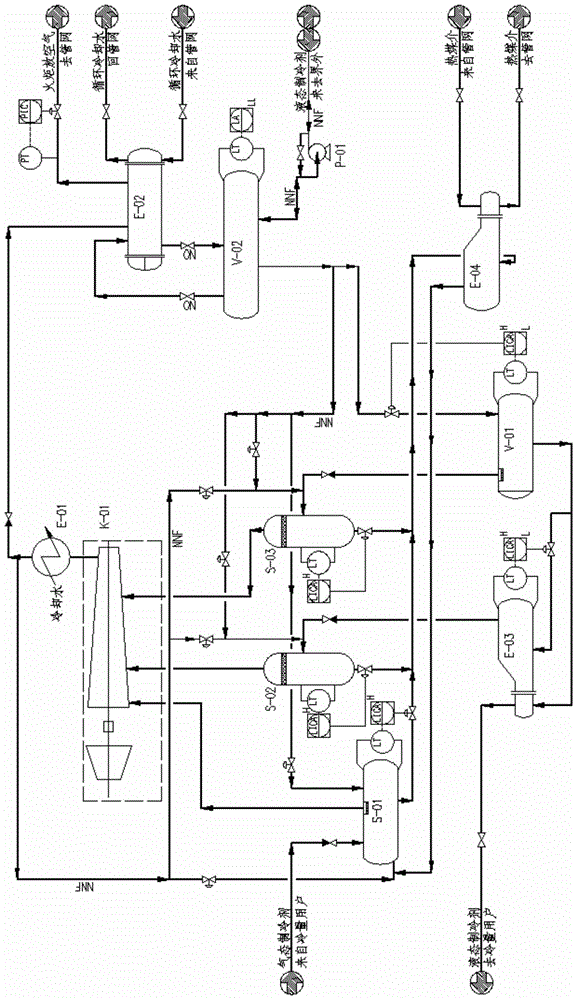

Image

Examples

specific Embodiment

[0030] The core equipment of the refrigerant discharge evaporation system is a partitioned heat exchange evaporator. The liquid refrigerant separated from the separator at the inlet of each compressor section is sent to the evaporator, heated and vaporized by the heat medium, and then sent to the inlet of the first compressor section.

[0031] The refrigerant is propylene. The gaseous propylene from the low-temperature methanol washing unit enters the first stage of the compressor after the entrained liquid propylene is separated by the first-stage inlet separator. The compressed gaseous propylene is condensed into liquid propylene by the circulating water through the outlet cooler and condenser, sent to the propylene buffer tank, and then decompressed into the propylene flash tank. The gaseous propylene flashed in the propylene flash tank enters the third-stage inlet of the compressor after separating the entrained liquid propylene in the three-stage inlet separator. The liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com