Textile component identification method based on hyperspectral imaging

A technology of hyperspectral imaging and textiles, which is applied in the fields of digital image processing and spectral analysis, can solve the problems of unquantifiable proportions and identification of textiles with various components, achieve fast data collection and processing, reduce identification costs, and avoid The effect of economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

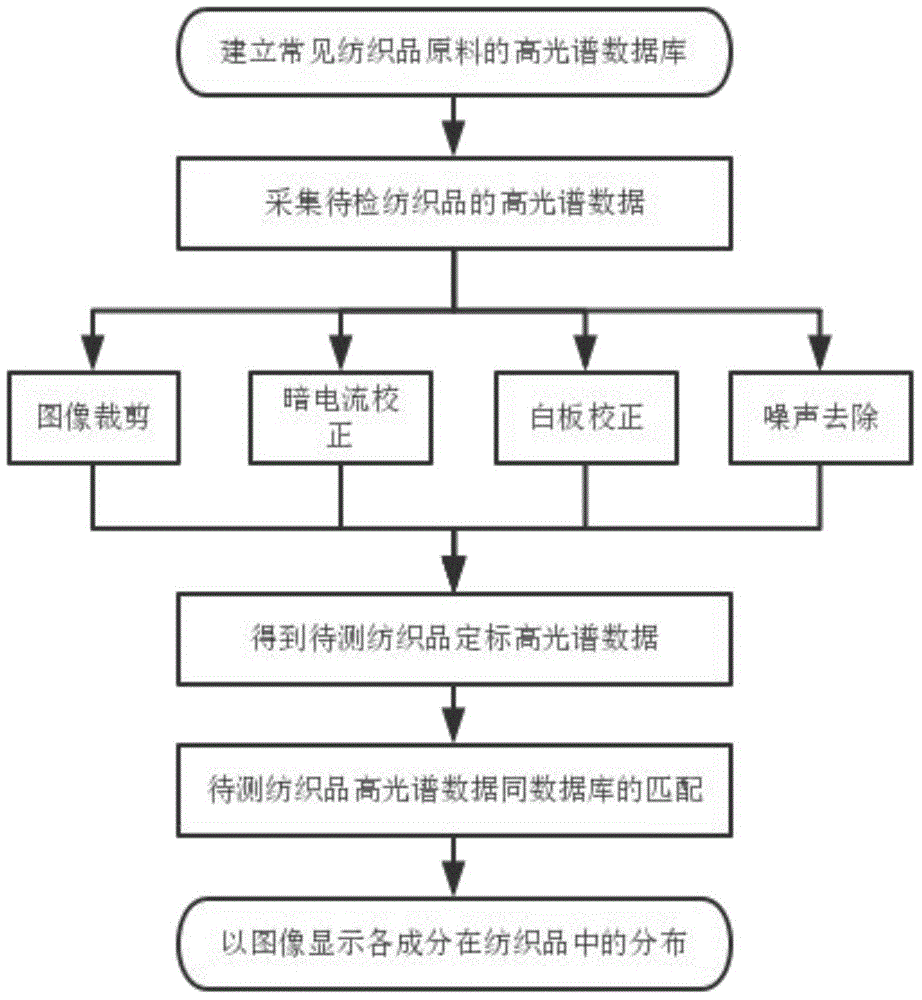

[0038] like figure 1 As shown, a method for identifying textile components based on hyperspectral imaging in this embodiment includes the following steps:

[0039] (1) Establish a hyperspectral database of common textile raw materials;

[0040] Collect all kinds of common textile raw materials. The above-mentioned common textile raw materials should include natural fibers such as cotton, wool, silk, and hemp; synthetic fibers such as polyester, nylon, acrylic, and polypropylene; fiber, metal fiber, carbon fiber and other inorganic fibers, the above fibers are evenly wound on the glass slide, and the fiber on the glass slide needs to be kept flat and completely covered during the winding process, so as to ensure the accuracy of its spectral data. The spectral data and images were obtained through the hyperspectral imager VNIR-400E of Themis Vision Company in the United States, and the above data and images were imported into ENVI software to establish a database for subsequent...

Embodiment 2

[0062] (1) Establish a hyperspectral database of common textile raw materials;

[0063] Collect all kinds of common textile raw materials. The above-mentioned common textile raw materials should include natural fibers such as cotton, wool, silk, and hemp; synthetic fibers such as polyester, nylon, acrylic, and polypropylene; fiber, metal fiber, carbon fiber and other inorganic fibers, the above fibers are evenly wound on the glass slide, and the fiber on the glass slide needs to be kept flat and completely covered during the winding process, so as to ensure the accuracy of its spectral data. The spectral data and images were obtained through the hyperspectral imager VNIR-400E of Themis Vision Company in the United States.

[0064] (2) Collect hyperspectral data of textiles to be inspected;

[0065] The spectral data and images of the textile samples to be inspected are also obtained through VNIR-400E, and the test conditions for the spectral collection of the textiles to be i...

Embodiment 3

[0088] (1) Establish a hyperspectral database of common textile raw materials;

[0089] Collect all kinds of common textile raw materials. The above-mentioned common textile raw materials should include natural fibers such as cotton, wool, silk, and hemp; synthetic fibers such as polyester, nylon, acrylic, and polypropylene; fiber, metal fiber, carbon fiber and other inorganic fibers, the above fibers are evenly wound on the glass slide, and the fiber on the glass slide needs to be kept flat and completely covered during the winding process, so as to ensure the accuracy of its spectral data. The spectral data and images were obtained through the hyperspectral imager VNIR-400E of Themis Vision Company in the United States.

[0090] (2) Collect hyperspectral data of textiles to be inspected;

[0091] The spectral data and images of the textile samples to be inspected are also obtained through VNIR-400E, and the test conditions for the spectral collection of the textiles to be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com