A preset performance tracking control method for motor servo system with hysteresis compensation

A servo system and preset performance technology, applied in the field of control, can solve the problems of not considering hysteresis nonlinearity, insufficient design, phase lag, etc., and achieve the effects of good parameter estimation, good robustness and bounded stability, and reasonable planning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

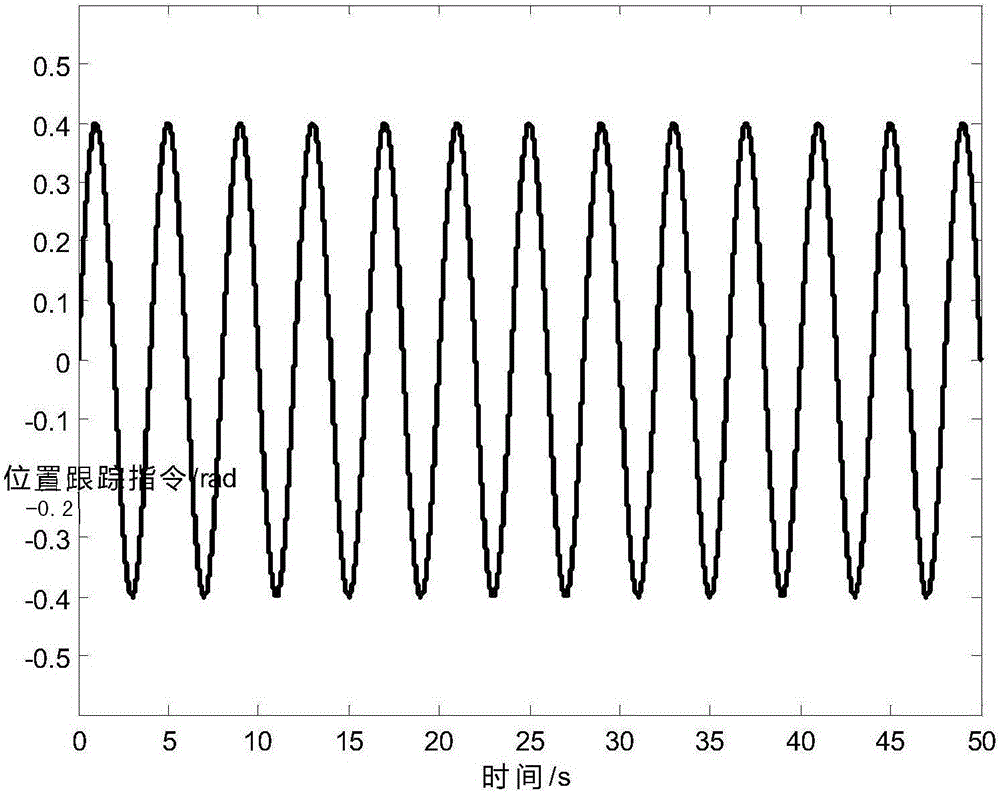

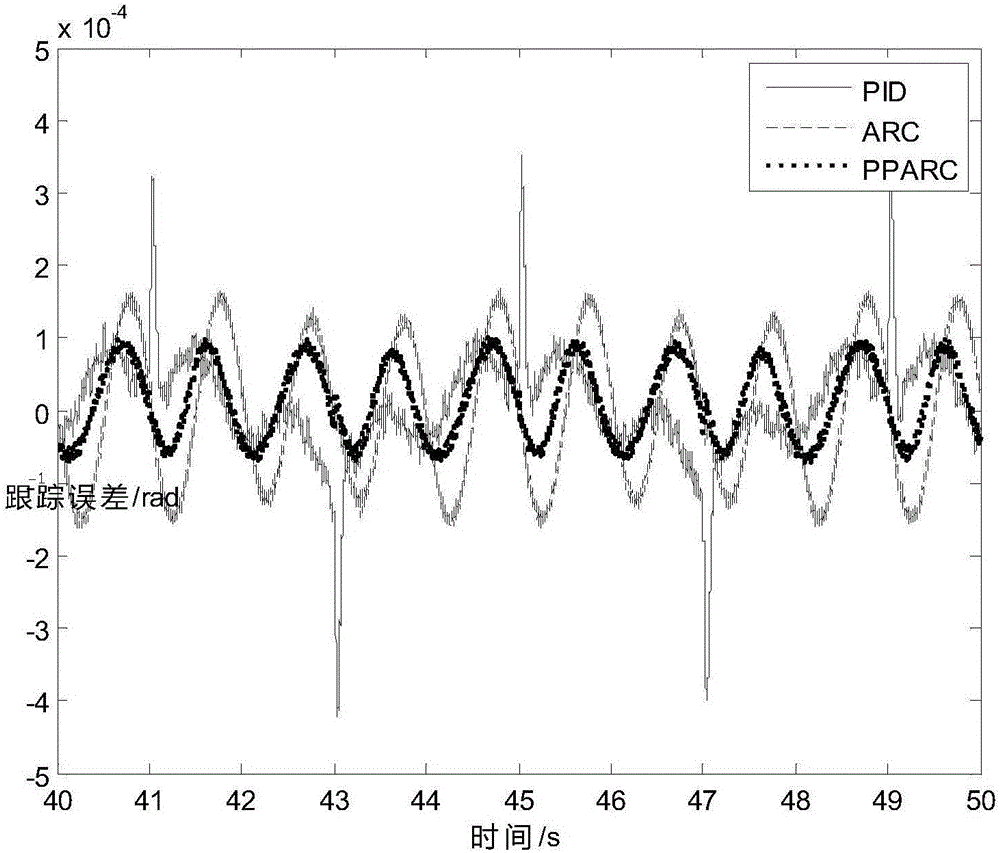

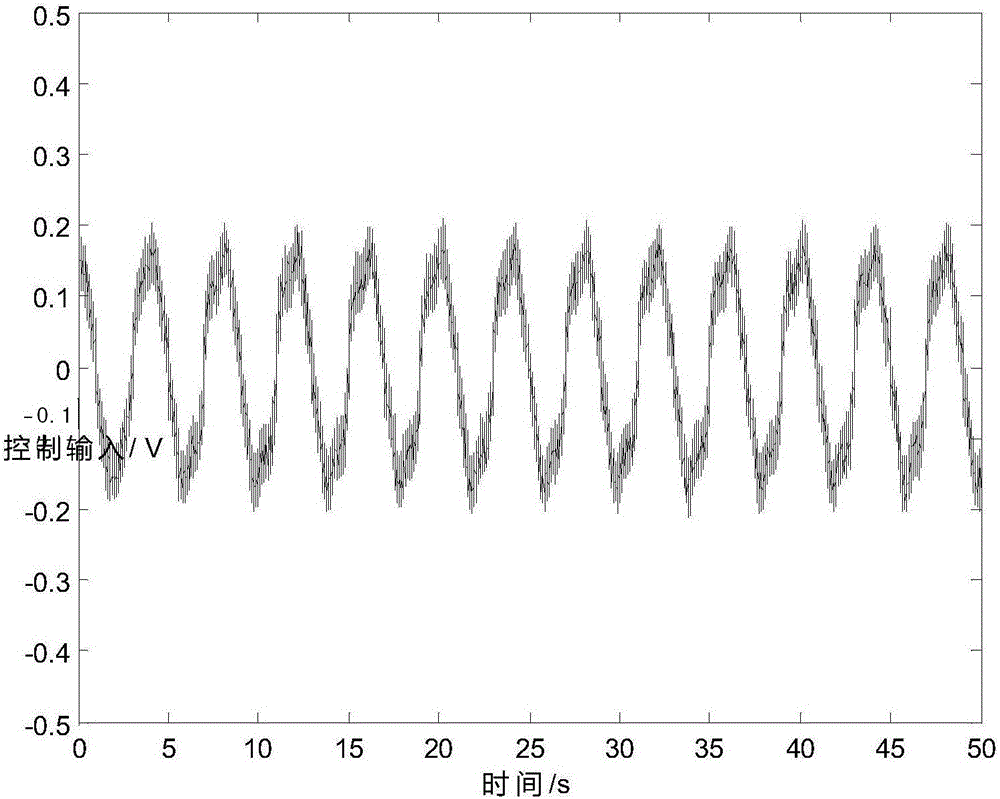

[0055] combine figure 1 , figure 2 with Figure 8 , a motor servo system preset performance tracking control method with hysteresis compensation, comprising the following steps:

[0056] Step 1, establish a motor servo system model with hysteresis, the specific method is as follows:

[0057] The hysteresis model is established as follows:

[0058]

[0059] In formula (1), u is the hysteresis model output, that is, the effective control input, c, a and B 1 is the hysteresis characteristic parameter, and satisfies c>B 1 , v is the output control quantity of the controller. Formula (1) can be transformed into:

[0060] u=cv(t)+d(v)

[0061]

[0062] u in formula (2) 0 and v 0 Indicates the initial value. Analyzing formula (2), we can see that the hysteresis model after conversion is composed of a linear term with a slope of c and an interference term d(v), and the boundary of the d(v) term is known.

[0063] Step 1.1, establish a motor servo system model with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com