RP-3 aviation kerosene cavitation numerical simulation method

A technology of aviation kerosene and RP-3, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Below in conjunction with specific embodiment, the present invention is described in further detail, and concrete steps include:

[0067] Step 1: Provide the formula of RP-3 aviation kerosene physical substitution model, table 1 is 5 embodiments of the present invention, and the component formula is calculated by mole percentage.

[0068] The component formula (mol percent) of table 1 embodiment

[0069] Kerosene Formula

n-dodecane

[0070] (The molar ratio of)

C 12 h 26

C 10 h 22

C 8 h 18

C 7 h 14

C 7 h 8

A

58%

32%

1%

1%

8%

B

58%

28%

1%

1%

12%

C

55%

30%

2%

3%

10%

D

52%

32%

3%

5%

8%

E

52%

28%

3%

5%

12%

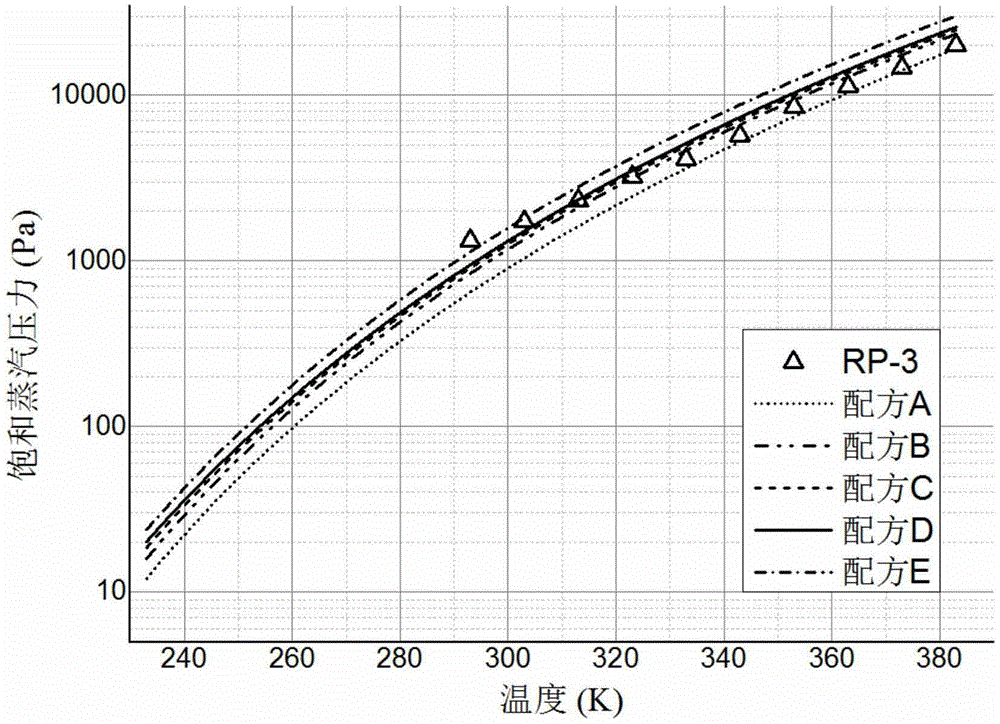

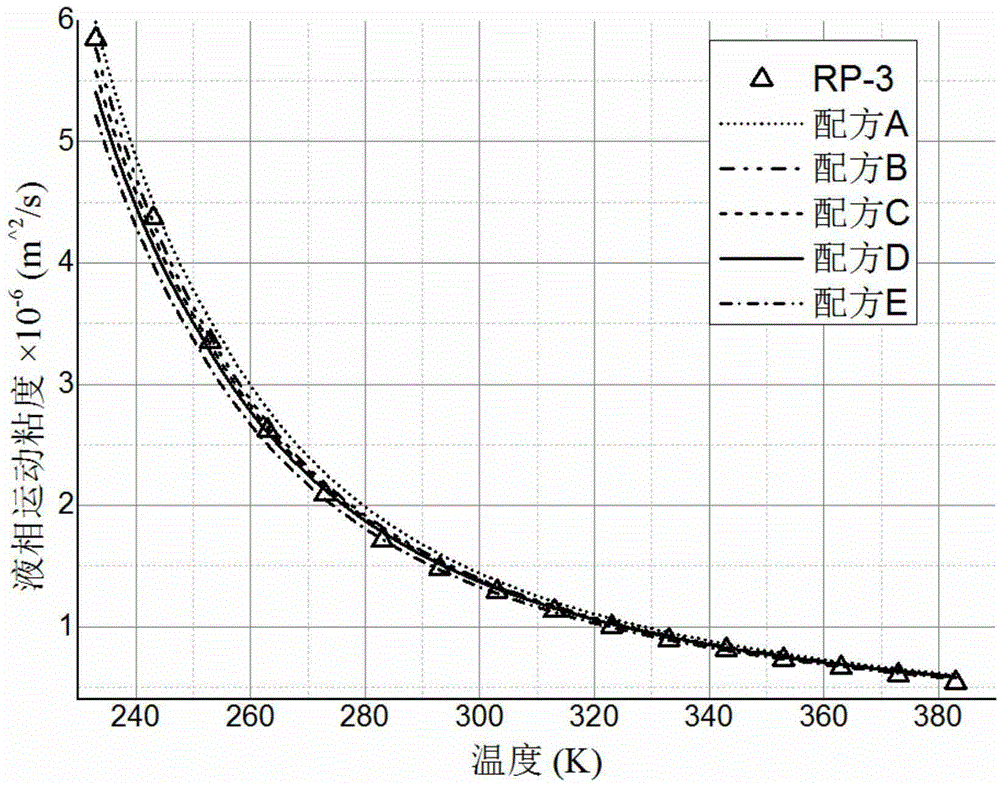

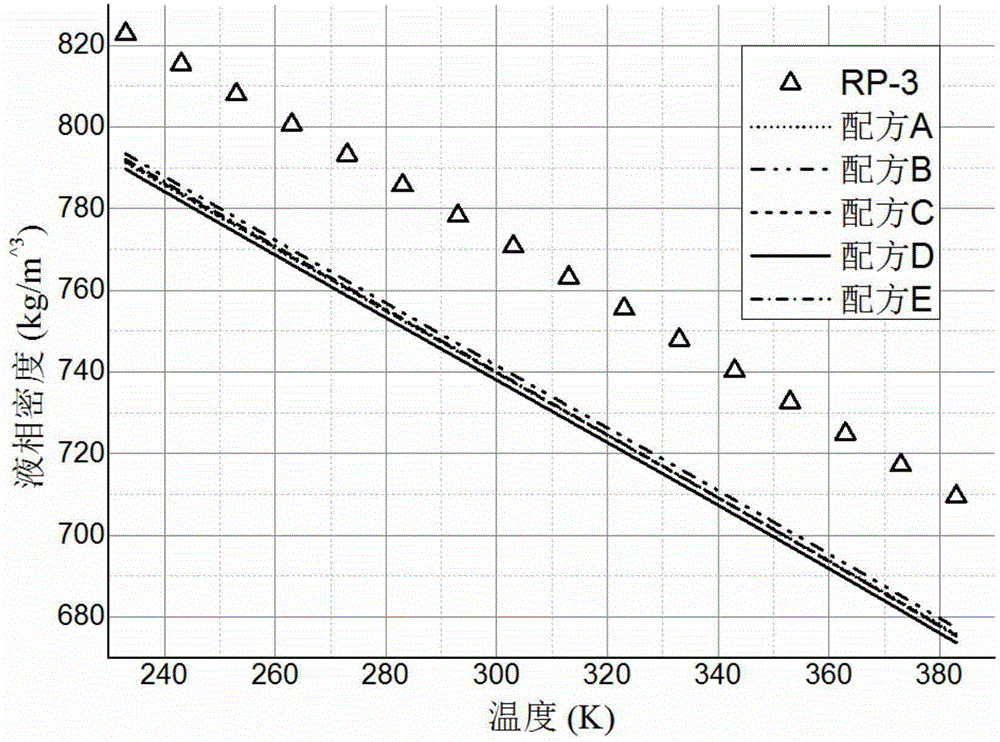

[0071] Step 2: Use the Supertrapp physical property analysis software developed by the National Institu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com