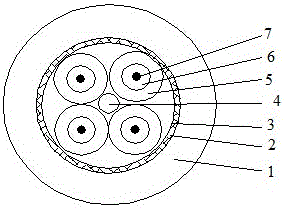

A bending-resistant shielded transmission line

A transmission line and bending-resistant technology, applied in the field of signal transmission lines, can solve the problems of complex process and high cost, and achieve the effects of low cost, high production efficiency and long bending life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]In this embodiment, the ingredients (wt.%) of the sheath layer of the bending-resistant shielded transmission line are: 40% of polyvinyl chloride powder; 28% of trioctyl trimellitate; 10% of calcium carbonate powder; 5% of kaolin powder %; environment-friendly calcium-zinc composite stabilizer 1.5%; stearic acid 0.05%; polystyrene rubber 9%; flame retardant 1.5%; The particle size of the kaolin powder is 70 microns, and the particle size of the kaolin powder is 20 microns. When the above raw materials are mixed, add them into the mixer in the following order: a) PVC powder with 30% of the total amount of PVC powder, b filler, c remaining PVC powder and polystyrene rubber, d environmentally friendly Calcium-zinc composite stabilizer and flame retardant, e-stearic acid and trioctyl trimellitate, the temperature during feeding is 60°C, after the feeding is completed, the temperature is raised to 145°C-150°C for mixing, after the mixing is completed, the The extruder is ext...

Embodiment 2

[0031] In this embodiment, the ingredients (wt.%) of the sheath layer of the bending-resistant shielded transmission line are: 41% of polyvinyl chloride powder; 27% of trioctyl trimellitate; 13.6% of calcium carbonate powder; 3.4% of kaolin powder %; environment-friendly calcium-zinc composite stabilizer 2.0%; stearic acid 0.07%; polystyrene rubber 8%; flame retardant 2.5%; The particle size of kaolin powder is 80 microns, and the particle size of kaolin powder is 30 microns. When the above raw materials are mixed, add them into the mixer in the following order: a) PVC powder with 40% of the total amount of PVC powder, b filler, c remaining PVC powder and polystyrene rubber, d environmentally friendly Calcium-zinc composite stabilizer and flame retardant, e-stearic acid and trioctyl trimellitate, the temperature during feeding is 60°C, after the feeding is completed, the temperature is raised to 145°C-150°C for mixing, after the mixing is completed, the The extruder is extrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com