Rare-earth permanent magnet and production method thereof

A rare earth permanent magnet and magnet technology, applied in the field of material manufacturing, can solve the problems of magnet remanence and reduction of coercivity, and achieve the effects of high coercivity, large magnetic energy product and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

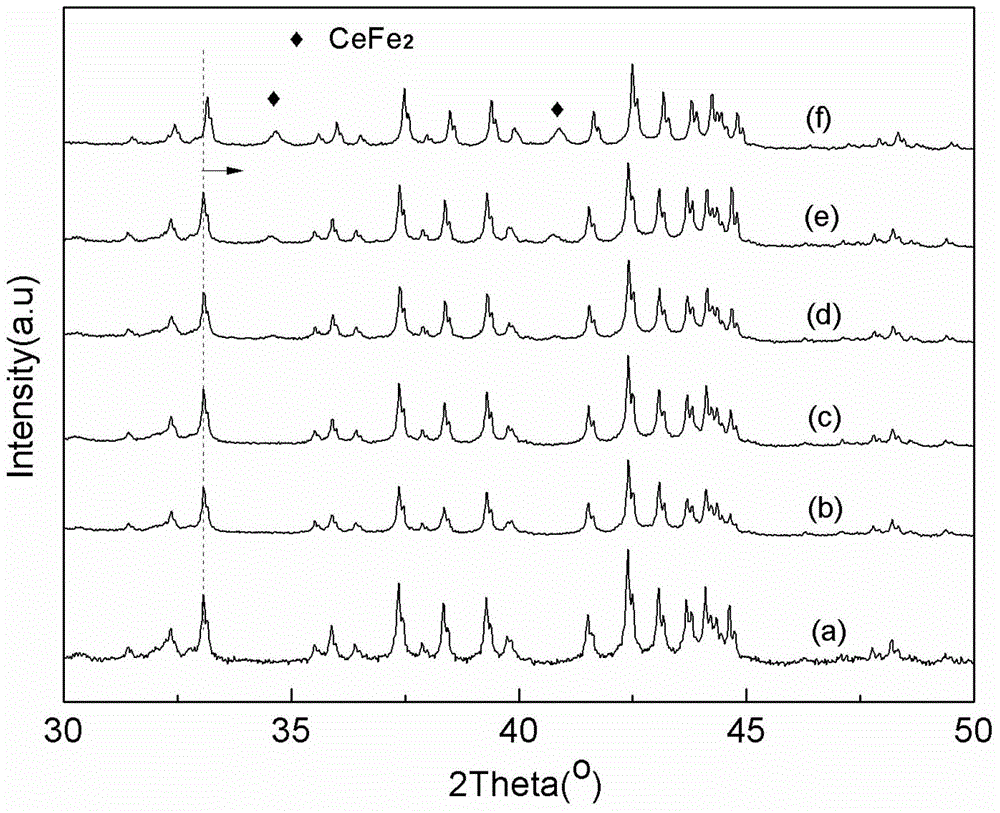

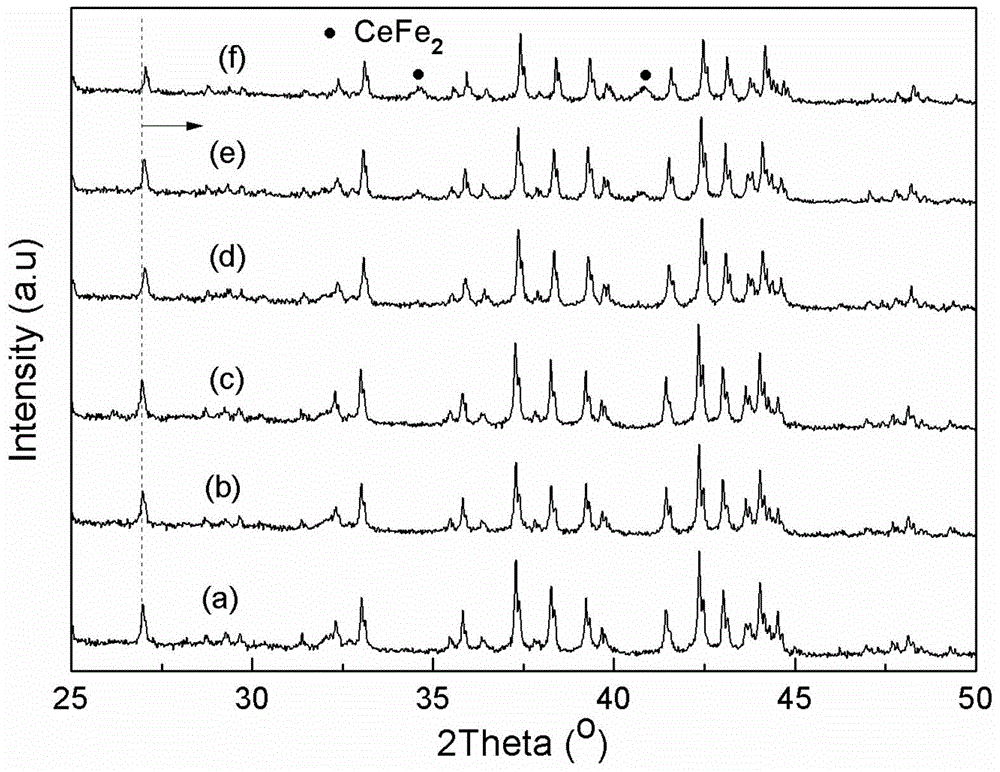

Image

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing the above-mentioned rare earth permanent magnet, comprising the following steps:

[0033] (1) Configure raw materials: according to MM a-b HRE b Fe e B d tm c The mass ratio of a certain amount of metal or alloy raw materials containing corresponding elements is configured, where MM stands for (LRE 1-x Ce x ), and x and 1-x are mass ratios, LRE is one or both of Pr and Nd, and HRE is one or two of La, Y, Gd, Tb, Dy, Ho, Er, Yb, Tm Several, TM is one or more of Al, Cu, Mn, Ga, Nb, Zr, and 0.24≤x≤0.6, 27≤a≤36, 0≤b≤10, 0≤c≤3, 0.8 ≤d≤1.5, e=100-a-d-c-d. Preferably, the raw material of the rare earth element is a mixed rare earth alloy. For example, an alloy containing at least two elements in the three elements of Ce, Pr, and Nd can be used, so that the separation process of the rare earth element is reduced, thereby avoiding energy loss in the separation process. consumption and environmental pollution.

...

Embodiment 1

[0057] A kind of rare earth permanent magnet, mass ratio chemical formula is [(Pr 0.2 Nd 0.8 ) 76 Ce 24 ] 27.5 Dy 3 Fe 68.3 al 0.1 Cu 0.1 B 1 , it can be known from the chemical formula that 24wt.% of Pr / Nd is replaced by Ce. The rare earth permanent magnet was prepared according to the preparation method of Comparative Example 2.

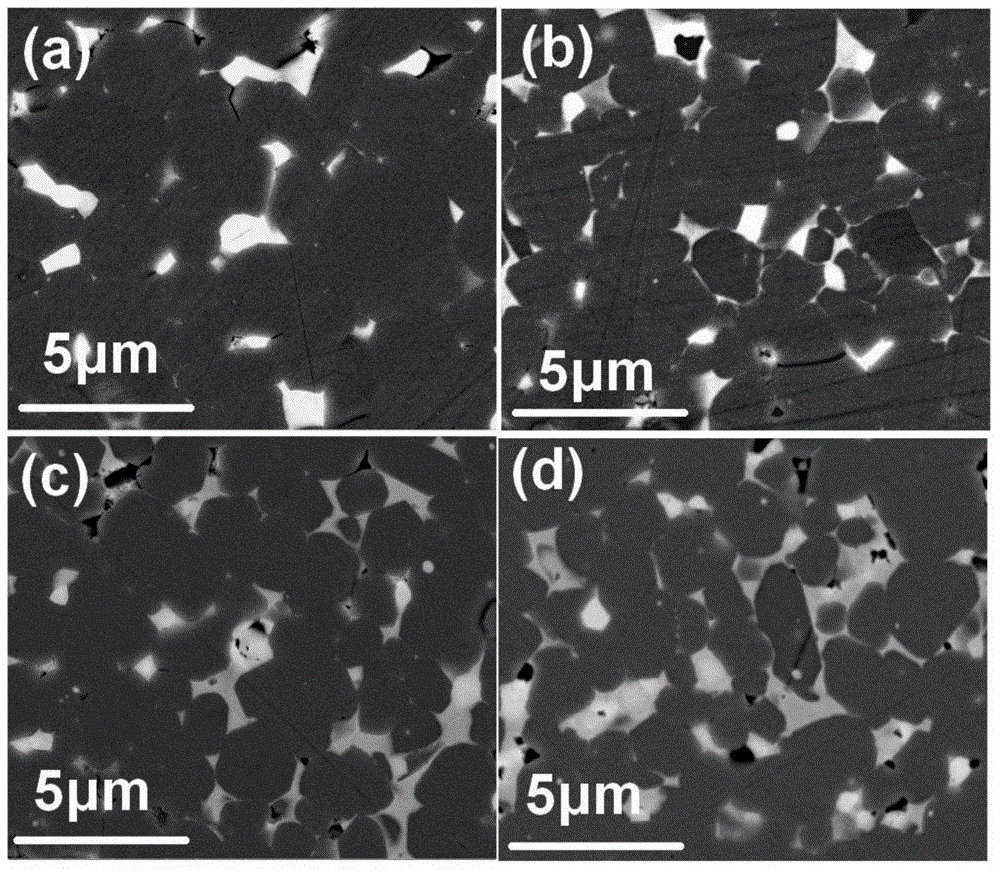

[0058] Image 6 It is the microstructure diagram of the rare earth permanent magnet of embodiment 1, as can be seen from the figure, the rare earth permanent magnet includes 2-14-1 phase, CeFe 2 phase and rare earth-rich phase, among which, CeFe 2 The phase is mainly distributed at the triangular grain boundary in the rare earth permanent magnet.

Embodiment 2

[0060] A kind of rare earth permanent magnet, mass ratio chemical formula is [(Pr 0.2 Nd 0.8 ) 68 Ce 32 ] 27.5 Dy 3 Fe 68.3 al 0.1 Cu 0.1 B 1 , it can be known from the chemical formula that 32wt.% of Pr / Nd is replaced by Ce. The rare earth permanent magnet was prepared according to the preparation method of Comparative Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com