Axial magnetic field modulation type composite motor with improved flux modulation structure and improved magnetizing direction

A technology of magnetization direction and axial magnetic field, which is applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of complex fixing method of magnetic ring and low utilization rate of permanent magnet, etc., and achieve compact and simple motor structure, improved mechanical stability, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

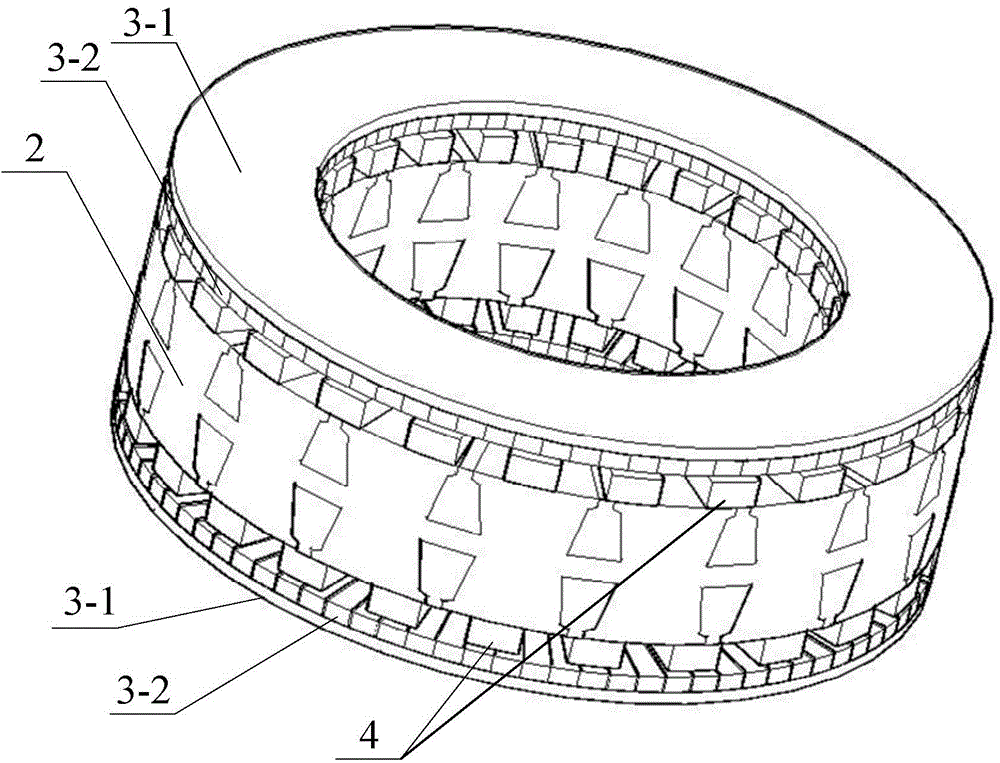

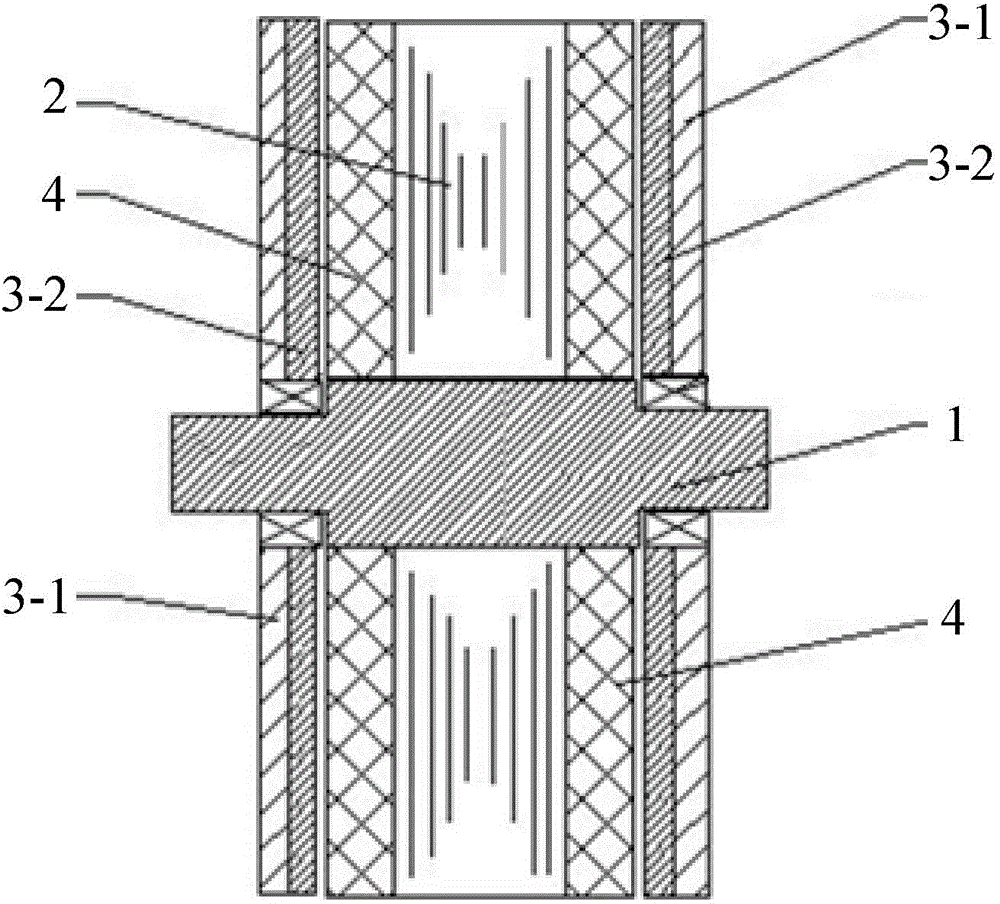

[0024] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the axial magnetic field modulation compound motor with the magnetic modulation structure and the magnetization direction improvement described in this embodiment, it includes a rotating shaft 1, a stator 2, two rotors and two magnetic modulation rings 4, and the stator 2 is fixed on On the rotating shaft 1, two rotors are symmetrically arranged on both sides of the stator 2 in a mirror image. There is an air gap between each rotor and the stator 2. Each rotor is connected to the rotating shaft 1 through a bearing.

[0025] Each air gap side surface of the stator 2 is bonded and fixed with a magnetic modulation ring 4, and the magnetic modulation ring 4 is fixedly connected with the rotating shaft 1; the magnetic modulation ring 4 is composed of magnetic modulation blocks evenly distributed along the circumferential direction;

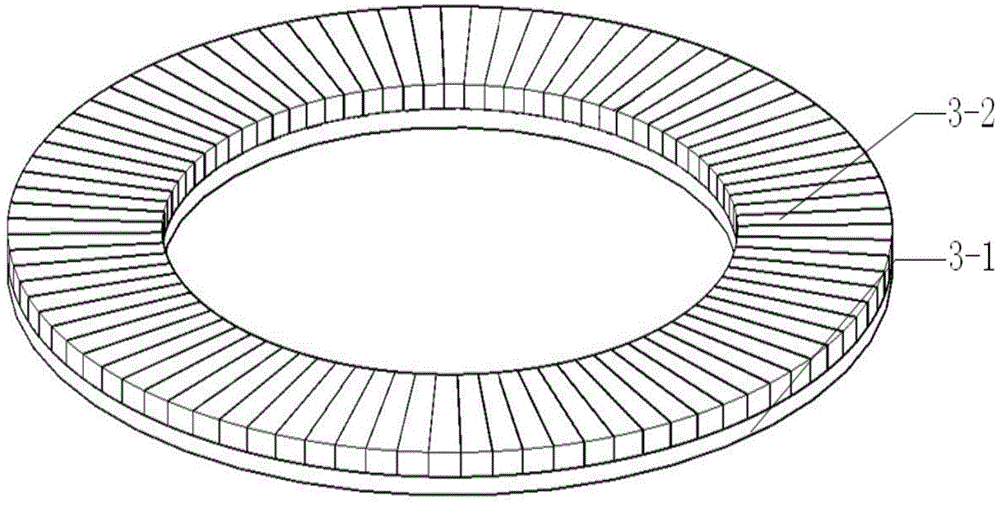

[0026] The rotor includes a rotor d...

specific Embodiment approach 2

[0028] Specific implementation mode two: the following combination Figure 1 to Figure 5 Describe this embodiment, this embodiment will further explain Embodiment 1, each air gap side surface of the stator 2 is evenly provided with a plurality of winding slots, the plurality of winding slots are evenly distributed along the circumferential direction of the stator side wall, the stator 2 two There is a one-to-one correspondence between the winding slots on the side surface of the air gap; each pair of winding slots is provided with an annular stator winding;

[0029] The number of pole pairs P of the permanent magnet ring 3-2 1 and ring stator winding pole pair number P 2 The sum is the number N of magnetic adjustment blocks in the magnetic adjustment ring 4 s .

[0030] Working principle: By analyzing the air-gap harmonic magnetic field obtained by adding a voltage source to the stator armature winding and the air-gap harmonic magnetic field generated by the permanent magne...

specific Embodiment approach 3

[0037] Specific Embodiment 3: This embodiment further describes Embodiment 1 or 2, and the material of the rotating shaft 1 is aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com