Melt-spinning method and melt-spinning apparatus for producing crimped yarn

A technology of melt spinning and crimping, which is applied in the direction of melt spinning, artificial filament heat treatment, filament/thread forming, etc., and can solve problems such as single filament bundle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

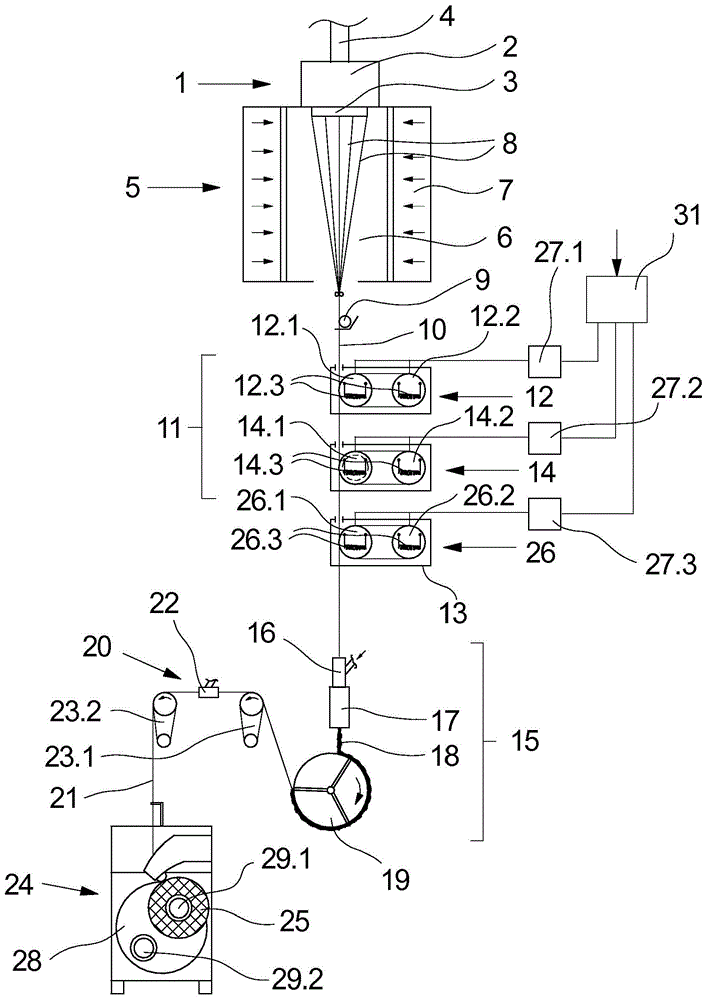

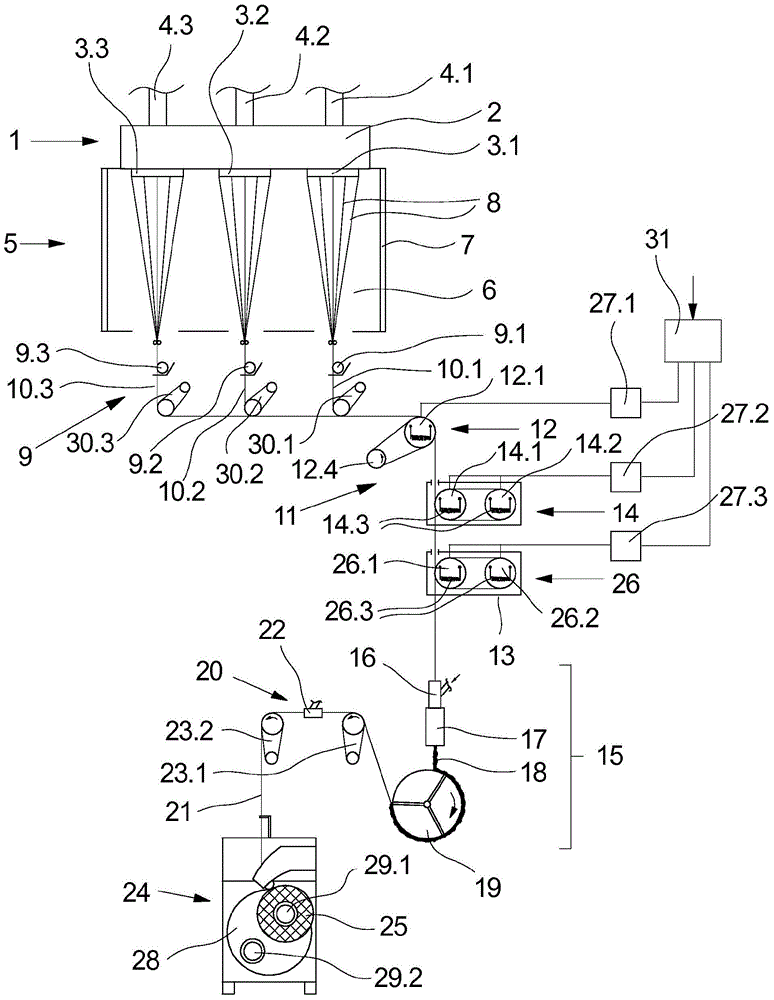

[0027] figure 1 A view of a first embodiment of a melt spinning apparatus for producing crimped filaments from thermoplastic polymers according to the invention is schematically shown in . This exemplary embodiment of the melt spinning device according to the invention is shown as a filament run, wherein such a melt spinning device is also used to produce a plurality of filaments side by side in parallel.

[0028] exist figure 1 The embodiment of the melt spinning apparatus according to the invention shown in has a spinning device 1, a cooling device 5, a drawing device 11, a texturing device 15, a finishing device 20 and a winding device 24, which are relative to the filament path arranged sequentially. The spinning device 1 is shown in this exemplary embodiment by a spinning head 2 . The spinneret 2 is designed to be heated in order to regulate the temperature of the components and lines used to conduct and distribute the polymer melt. The spinning head 2 thus has on its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com