Plant Extract Negative Pressure Concentration System

A negative pressure concentration and extraction technology, which is applied in the direction of evaporator accessories, evaporation, fractionation, etc., can solve the problems of high heat consumption, high boiling temperature of initial extraction liquid, and low concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

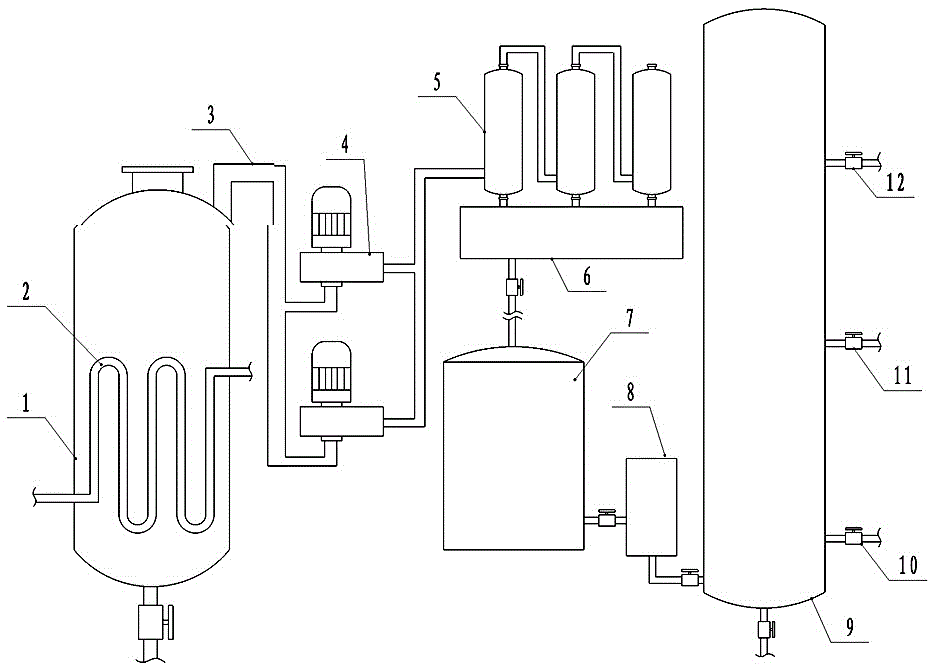

[0007] Example: such as figure 1 As shown, a negative pressure concentration system for plant extracts, the concentration tank 1 of the system is equipped with a steam heating pipe 2, the steam outlet pipe 3 of the extraction liquid is installed above the concentration tank 1, and the steam outlet pipe 3 is connected to the condensing The inlet pipe at the top of the condenser 5, the condenser 5 is not less than two, the inlet pipe at the top of the condenser 5 and the outlet pipe at the tail end are connected together to form a series connection, and the lower end of each condenser 5 has a liquid outlet pipe connected to the temporary solvent. In the storage tank 6, the temporary solvent storage tank 6 is connected to the solvent storage tank 7, and no less than two vacuum pumps 4 are installed in parallel on the steam outlet pipe 3 of the concentration tank, and the exhaust pipes of the vacuum pumps 4 are connected in parallel. After being connected to the inlet pipe at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com