A waste gas purifier for chemical and pharmaceutical industries

A technology of exhaust gas purifier and medicine, applied in the field of air purification, can solve the problems of not being able to completely purify waste gas impurities, unable to completely purify waste gas impurities, reducing work efficiency, etc., achieving a wide range of use, convenient replacement and installation, and improving work efficiency The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

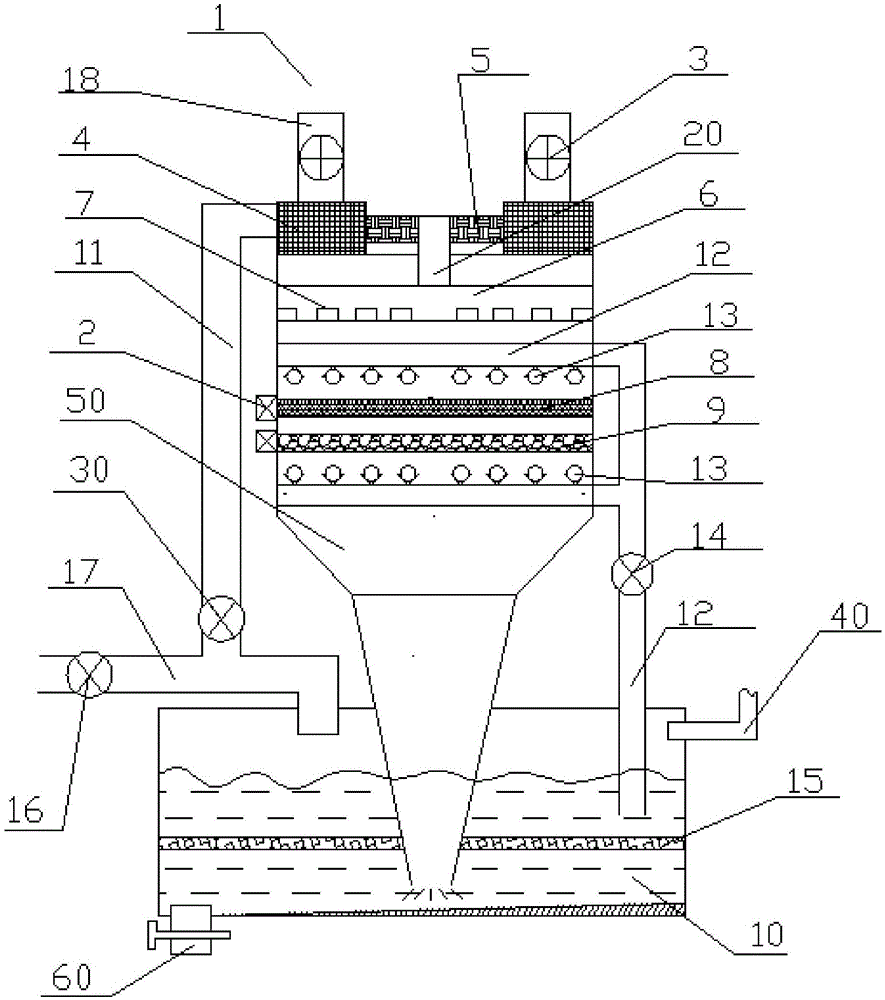

[0025] Such as figure 1 As shown, the first specific embodiment of the present invention is: an exhaust gas purifier for chemical and pharmaceutical industries, which includes a body 1 and a water storage tank 10, the water storage tank 10 is a closed cavity and is arranged on the body 1 Below, filter water is filled in the reservoir 10, and the liquid level in the reservoir 10 is 2 / 3 to 5 / 6 of the total height of the inner cavity of the reservoir, and the preferred liquid level in this embodiment is 2 / 3. A funnel 50 is arranged at the bottom of the body 1, and the lower end of the funnel 50 passes through the closed upper wall of the water storage tank 10 and is inserted under the liquid level in the water storage tank 10. The waste gas is introduced into the water storage tank 10, and the liquid level in the water storage tank 10 exceeds the mouth of the funnel 50 and the mouth of the funnel 50 is completely submerged under the liquid surface, so that the waste gas discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com