A kind of mixed shot blasting method

A mixed blasting and shot blasting technology, applied in used abrasive treatment devices, abrasives, metal processing equipment, etc., can solve problems such as affecting work efficiency, multiple clamping, etc., reducing labor intensity and improving processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

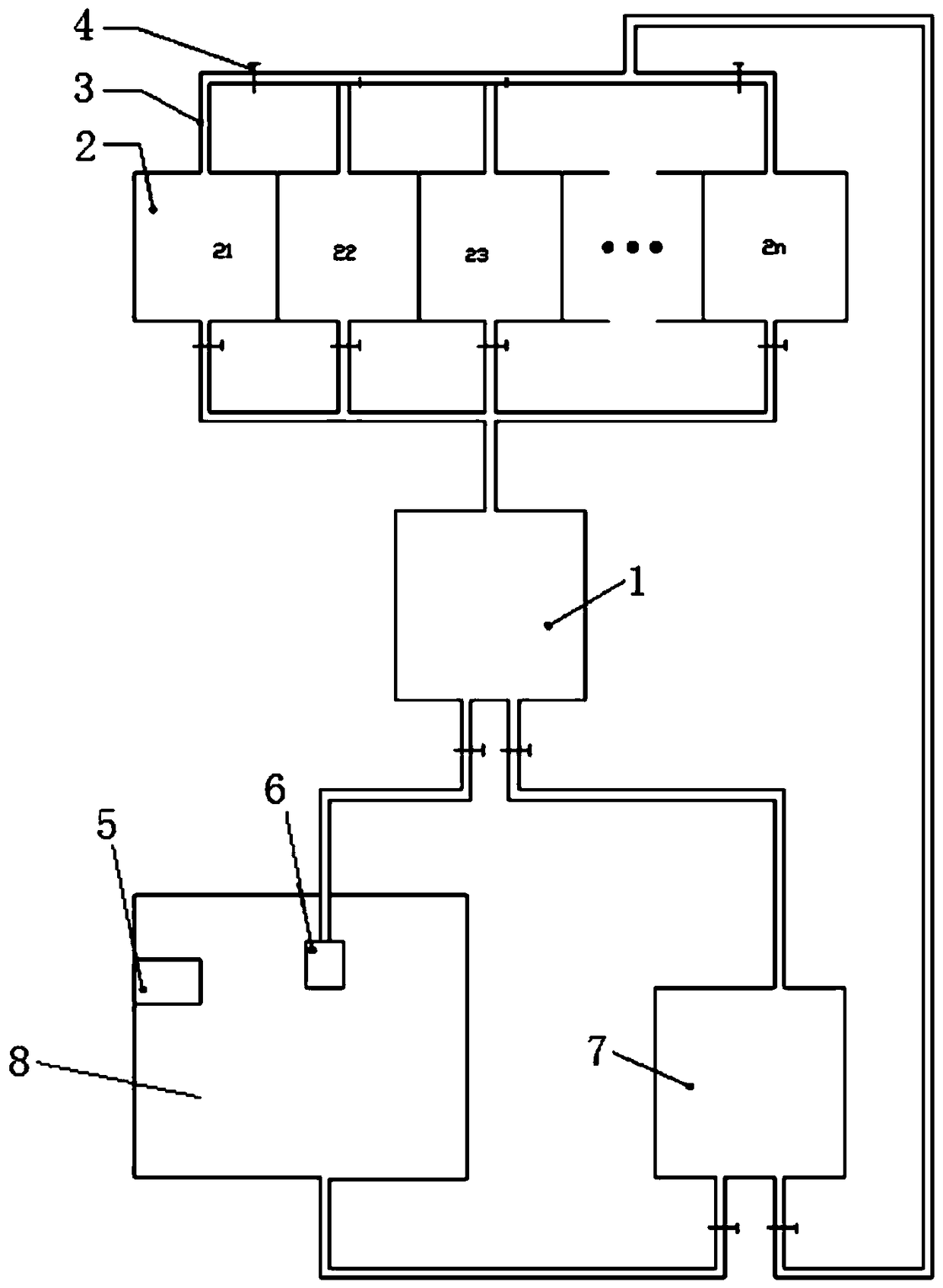

[0036] A mixed shot peening method, combining process and figure 1 described as follows:

[0037] method one

[0038] A variety of projectile spraying process in different time periods: it can be one kind, two or more kinds of projectiles, in the same clamping, the same device can be shot peened in different time periods through different channels and different specifications,

[0039] For example: according to the process requirements, the pipeline 3 connecting the main material bin 1, the auxiliary material bin 2, the shot blaster 8 and the projectile recovery device 7 is equipped with a valve 4, and if the projectiles in the auxiliary material bin 2 are required, the 21 valves are opened. After the corresponding valve 4 passes through the main material bin 1, the shot peening manipulator 6 performs shot peening on the workpiece. After a certain period of shot peening, the corresponding valve 21 is closed, the shot peening manipulator 6 stops peening, and the shot peening m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com