Low-cost simple mold of composite materials for airplanes and fast manufacturing method

A composite material, low-cost technology, applied in the field of low-cost simple mold and rapid manufacturing of composite materials for aircraft, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution can also be realized through the following technical measures and the present invention will be further described below in conjunction with the accompanying drawings:

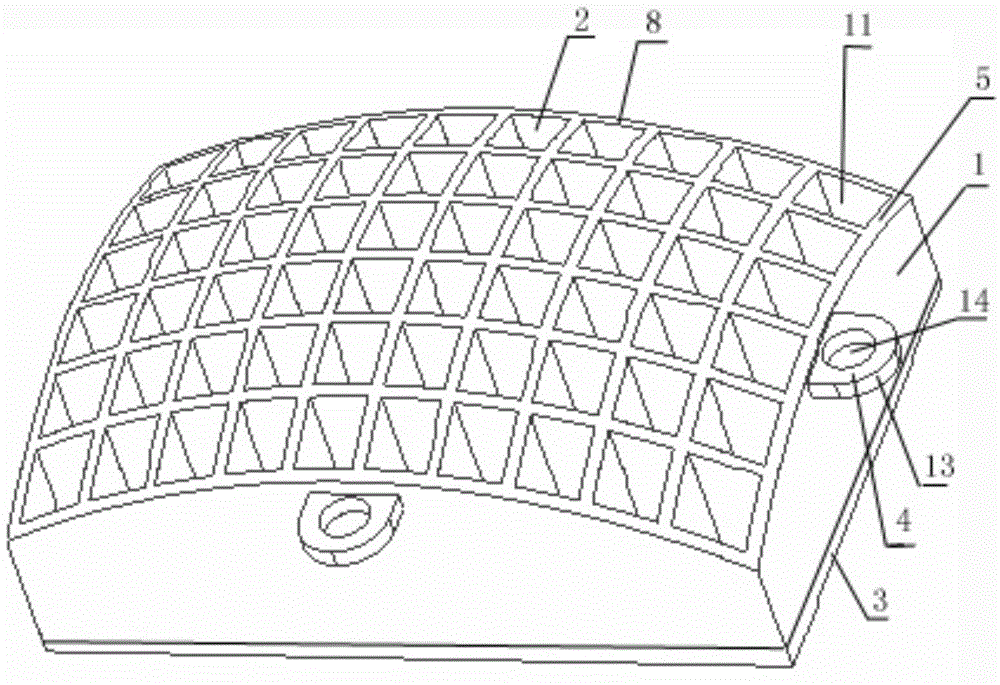

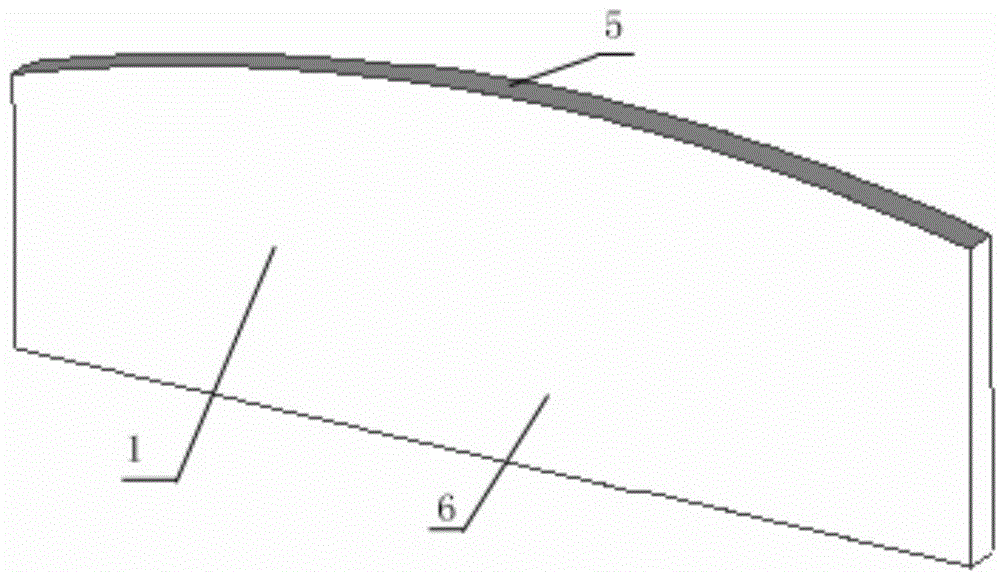

[0022] figure 1 is a schematic diagram of the three-dimensional structure of the present invention, Figure 6 It is a schematic cross-sectional view of the present invention, consisting of a U-to-rib (1), a V-to-rib (2), a base (3), a craft ear hole base (4), a convex profile (5), a support (6), Convex profile (8), support body (9), grid empty groove (11), filler (12), process earhole seat support body (13), process positioning hole (14), it is characterized in that: mainly A grid-like low-cost simple mold is composed of U-directional ribs (1), V-directional ribs (2), and base (3). The material used is ordinary steel, and the grids with the same spacing are adopted, and the spacing size is 200 ~300mm, the number of grids is determined by the size of the composite material. Filler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com