Vibration-absorption protection film and preparation method thereof

A technology of protective film and protective layer, used in protective equipment, chemical instruments and methods, protective clothing, etc., can solve the problem that the probability of damage to mobile phone display components cannot be effectively reduced, the damage cannot be protected, and the impact resistance is poor. And other problems, to achieve the effect of good vibration absorption and anti-vibration function, good fit effect, good elasticity and anti-shock function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

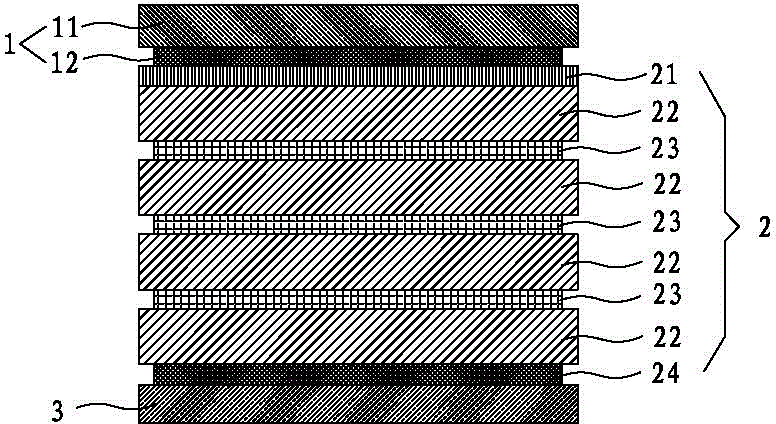

[0057] Such as figure 1 As shown, the anti-vibration and anti-shock protective film provided in this embodiment includes: a buffer layer 2 , a protective layer 1 and a peeling layer 3 . The buffer layer 2 includes 4 layers of transparent films 22: the uppermost layer of PET film, the second layer of PC film, the third layer of PVC film, the bottom layer of PC film, and the uppermost layer of PET film and the second layer of PC film. Adhesive layer 23, is arranged on the adhesive layer 23 between the second layer of PC film and the third layer of PVC film, is arranged on the adhesive layer 23 between the third layer of PVC film and the fourth layer of PC film, is arranged on the most The UV coating 21 on the upper surface of the upper PET film is arranged on the low-tack adhesive layer 24 on the lower surface of the bottom PC film. The protective layer 1 further includes a protective layer base film 11 and a protective layer adhesive layer 12 .

[0058] Wherein, the PET film...

Embodiment 2

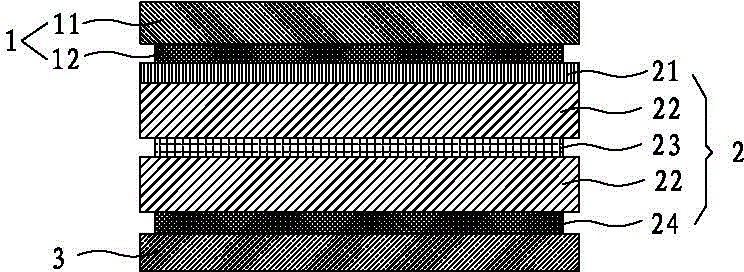

[0063] Such as figure 2 As shown, the anti-vibration and anti-shock protective film provided in this embodiment includes: a buffer layer 2 , a protective layer 1 and a peeling layer 3 . The buffer layer 2 includes 2 layers of PET films: the uppermost layer of PET film, the lowermost layer of PC film, the adhesive layer 23 arranged between the uppermost layer of PET film and the lowermost layer of PC film, and the upper surface of the uppermost layer of PET film. The UV coating 21 is arranged on the low-tack adhesive layer 24 on the bottom surface of the bottom PC film. The protective layer 1 further includes a protective layer base film 11 and a protective layer adhesive layer 12 .

[0064] Wherein, the PET film used in the buffer layer 2 is an optical-grade transparent PET film with a light transmittance greater than 95% and a haze lower than 3%; the PC film is a transparent PC film with a light transmittance greater than 93% and a haze lower than 1%. Among them, the thic...

Embodiment 3

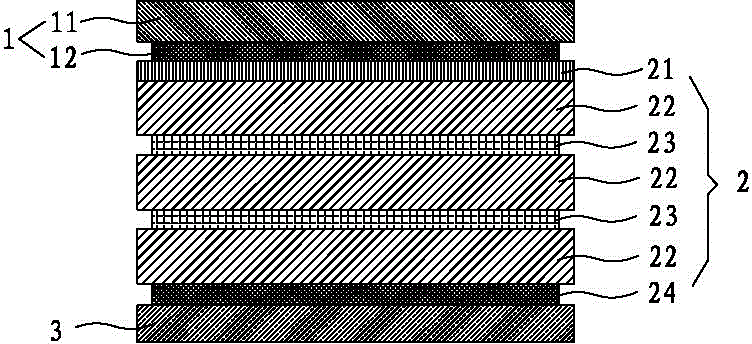

[0070] Such as image 3 As shown, the anti-vibration and anti-shock protective film provided in this embodiment includes: a buffer layer 2 , a protective layer 1 and a peeling layer 3 . The buffer layer 2 includes 3 layers of PET films: the top layer of PET film, the second layer of PVC film, the bottom layer of PC film, and the adhesive layer 23 arranged between the top layer of PET film and the second layer of PVC film is arranged on The bonding layer 23 between the second layer of PVC film and the bottom PC film is arranged on the UV coating 21 on the upper surface of the top PET film, and the low-tack adhesive layer 24 is arranged on the bottom surface of the bottom PC film. The protective layer 1 further includes a protective layer base film 11 and a protective layer adhesive layer 12 .

[0071] Wherein, the PET film used in the buffer layer 2 is an optical-grade transparent PET film with a light transmittance greater than 95% and a haze lower than 3%; the PC film is a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com