A kind of disperse black azo dye mixture

An azo dye and mixture technology, used in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of easy migration of dyes, easy to produce color difference, and the surface is not smooth enough, and achieve good dyeing stability and good dyeing fastness. , Excellent light fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

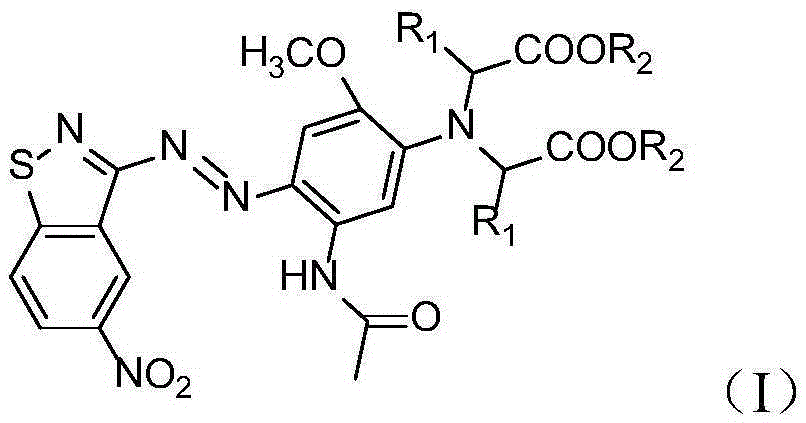

[0042] The preparation method of dye A:

[0043] Sodium nitrite (6.9 g, 0.1 mol, 100 percent) was added to 15 mL of 96% concentrated sulfuric acid, stirred for 5 minutes, and left at 10-15 ° C for 1 hour to obtain a nitrosyl sulfuric acid solution for later use. The diazo component (19.5g, 0.1mol, folded) with the structure shown in (a) was dissolved in 15mL of concentrated sulfuric acid, and the above-mentioned nitrosylsulfuric acid was diazotized slowly at 0-5°C (ice bath), and the reaction After 1-1.5 hours, place it in an ice bath to obtain the diazonium salt for later use. Another coupling component (32.4 g, 0.1 mol, folded) with the structure shown in (b) was dissolved in 10 mL of glacial acetic acid. Slowly drop into the above-mentioned diazonium salt solution at 0-5°C, continue to stir for 10 minutes after the addition, let it stand still, and obtain 48.3g (100%) of the green light blue dye with the structure shown in (I-1) by suction filtration , and the molar yield...

Embodiment 1

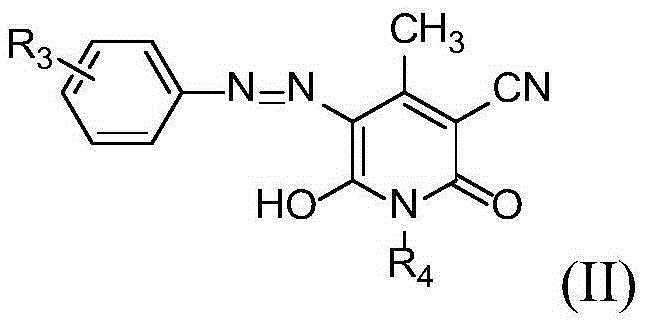

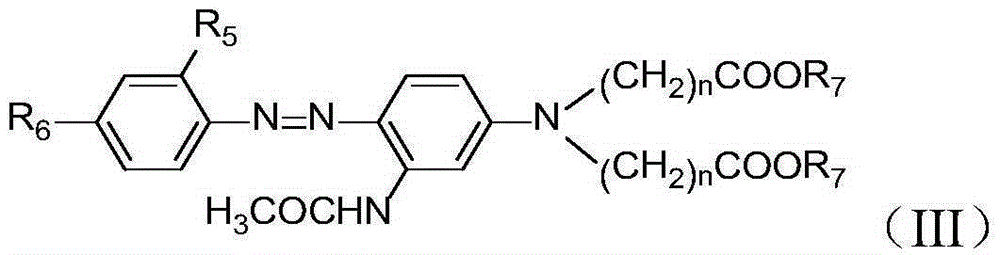

[0047] 22 grams of component A of formula (I-1), 23 grams of component B of formula (II-2), 16 grams of component C of formula (III-1), and 27 grams of component of formula (IV-3) Part D, 12 grams of component E of formula (V-1), 90 grams of naphthalenesulfonic acid formaldehyde condensate (dispersant NNO), blended with water, ground and dispersed with a grinder, and spray-dried to obtain a commercial dye. The dye can provide a deep black color with excellent fastness properties to the fabric.

Embodiment 2

[0049] 31 grams of component A of formula (I-1), 21 grams of component B of formula (II-1), 19 grams of component C of formula (III-5), and 18 grams of component of formula (IV-3) Part D, 11 grams of component E of formula (V-2), 100 grams of methylnaphthalenesulfonic acid formaldehyde condensate (dispersant MF), after adding water and blending, grinding and dispersing with a grinder, and spray drying to obtain commercial dyes . The dye can provide a deep black color with excellent fastness properties to the fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com