Diamond Segment Counting Device and Control Strategy of Diamond Segment Counting Device

A diamond cutter head and counting device technology, applied in the physical field, can solve the problems of low accuracy of weighing conversion, error-prone, high labor intensity, etc., and achieve the effect of avoiding long-term stay, accurate counting and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

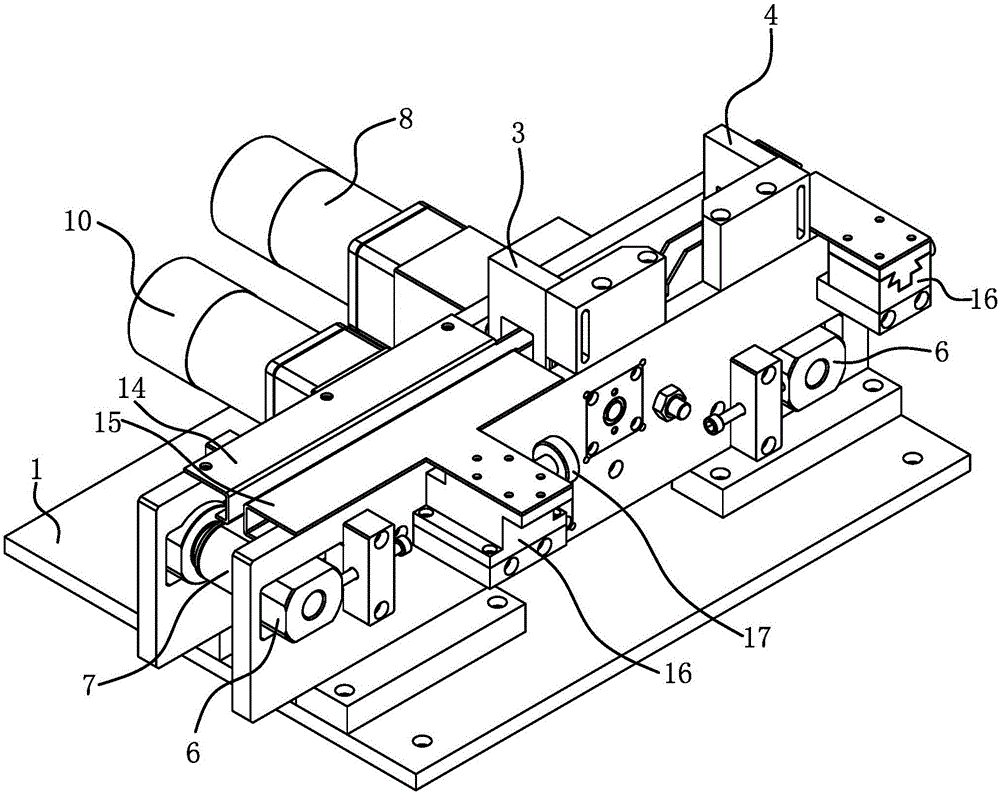

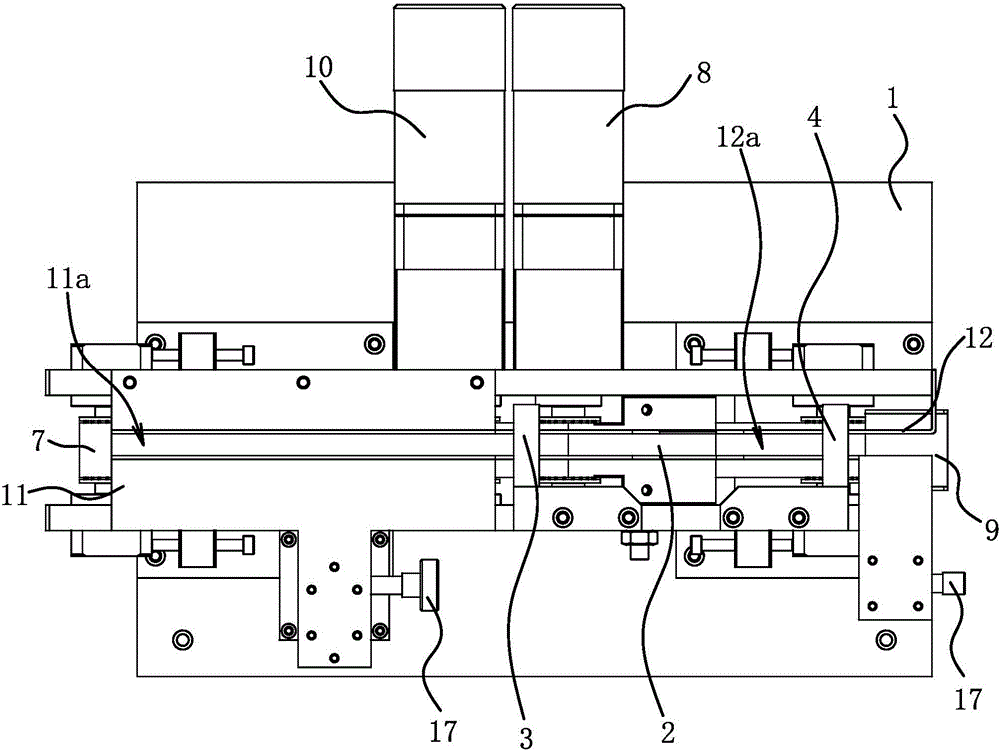

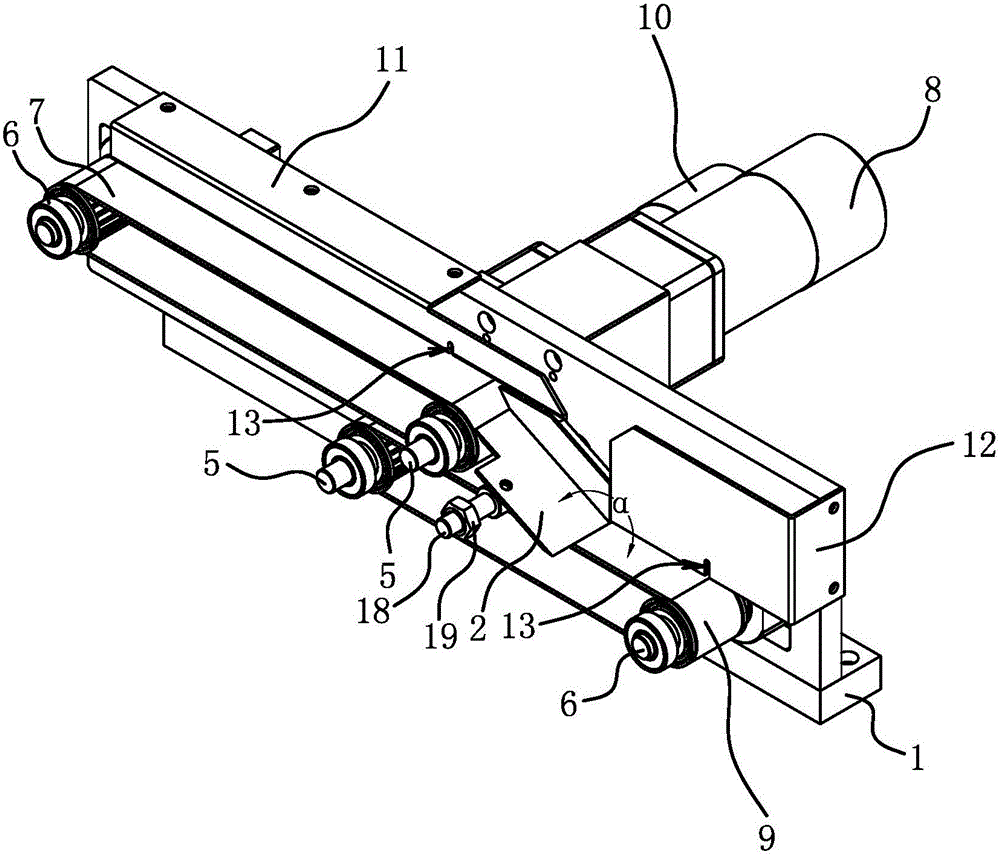

[0026] Such as Figure 1 to Figure 3 As shown, the diamond cutter head counting device includes a base 1, a first-level cutter head horizontal transmission structure, a second-level cutter head horizontal transmission structure, a swash plate 2, a first-level counting sensor 3, a second-level counting sensor 4 and a host computer.

[0027] The base 1 is the basic part of the diamond cutter head counting device, the base 1 can be fixed on the support, and the vibrating plate is also installed on the support.

[0028] The horizontal transmission structure of the primary cutter head and the horizontal transmission structure of the secondary cutter head are roughly the same, both including a transmission belt, a driving wheel 5, a tensioning wheel 6 and a servo motor; the driving wheel 5 and the tensioning wheel 6 are positioned on the base 1, The transmission belt is tensioned by the driving pulley 5 and the tensioning pulley 6, the housing of the servo motor is fixed on the base...

Embodiment 2

[0038] The structure and principle of this embodiment are basically the same as those of Embodiment 1. The basic similarities will not be described redundantly, and only the differences will be described. The differences lie in the control strategy of the diamond tip counting device. Specifically, the control strategy of the diamond cutter head counting device adopts a fixed total and difference control strategy:

[0039] First input the total number of workpieces to be counted in the host computer, such as 100; the set difference between the counting value of the primary counting sensor 3 and the counting value of the secondary counting sensor 4, such as 1.

[0040] Then control the first-level servo motor 8 and the second-level servo motor 10 to start counting, the vibrating disc will input the diamond cutter head into the first-level conveying channel 11a, and the first-level transmission belt 7 will convey the cutter head to the swash plate 2, and the cutter head will move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com