Belt conveyor capable of being horizontally bent

A conveyor and curved belt technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of reduced recovery rate, limited increase, complicated steps, etc., to reduce the loss, wear and tear of edge coal. The effect of small size and simplified transportation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

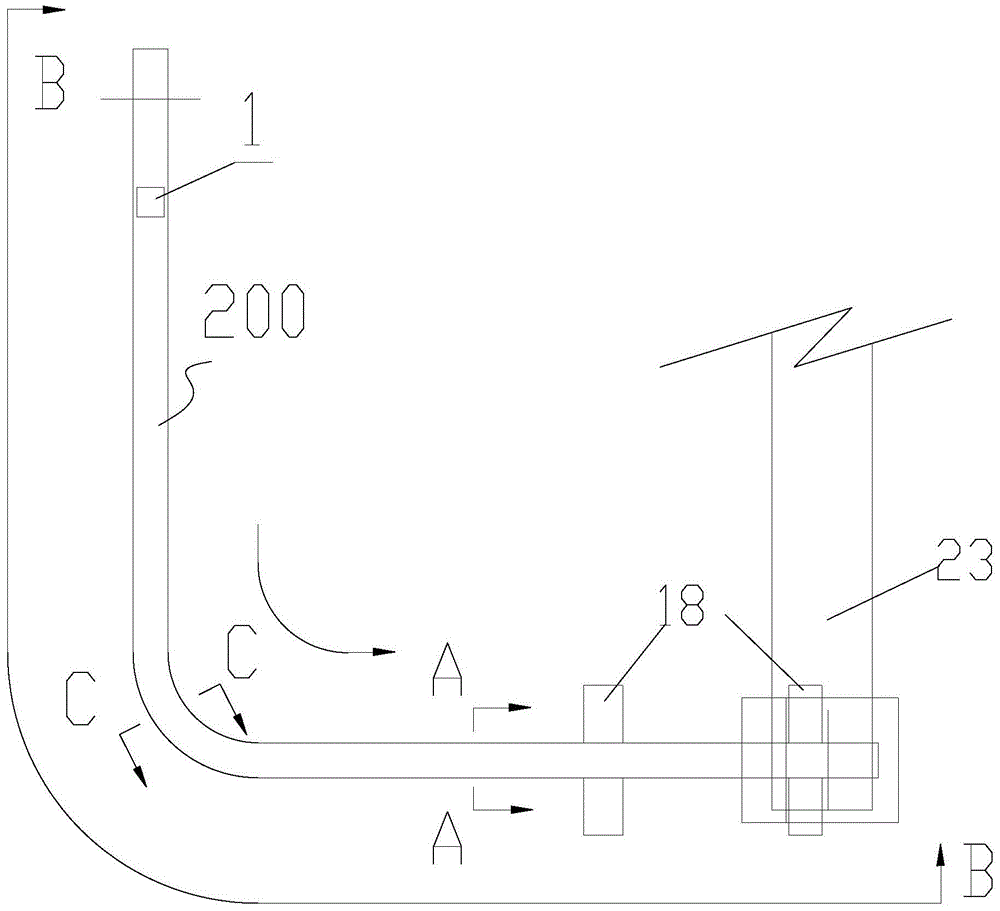

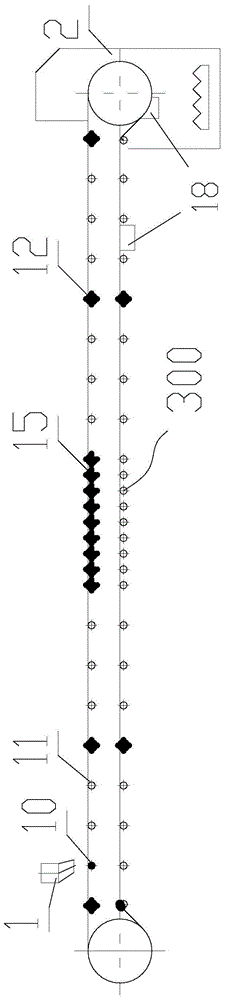

[0042] Such as figure 1 , figure 2 with image 3 As shown, a horizontally bendable belt conveyor includes a frame 100, a conveyor belt 200 and an idler roller set 300 arranged below the conveyor belt. One end of the conveyor belt is provided with a loading device 1 and the other end is provided with an unloading device 2 . Near the unloading device 2 side, a cleaning device 18 is arranged below the conveyor belt.

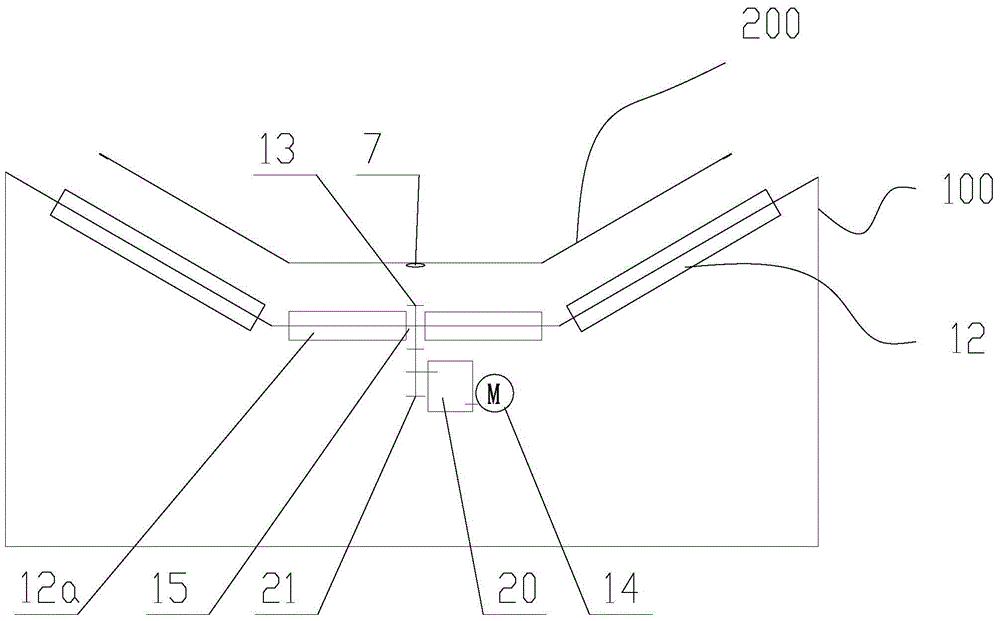

[0043] Such as Figure 5 to Figure 7 As shown, the conveyor belt is a multi-section split structure, each section of the conveyor belt includes a rectangular body 3, the tail of the body is symmetrically extended with a fan-shaped rack mounting part 4, and the second rack mounting part 4 is provided with a fan-shaped concentric I-shaped The front end of the rack 5 is provided with an I-shaped tooth groove 6 corresponding to the rack 5 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com