Production method of steel slag aggregate for asphalt concrete

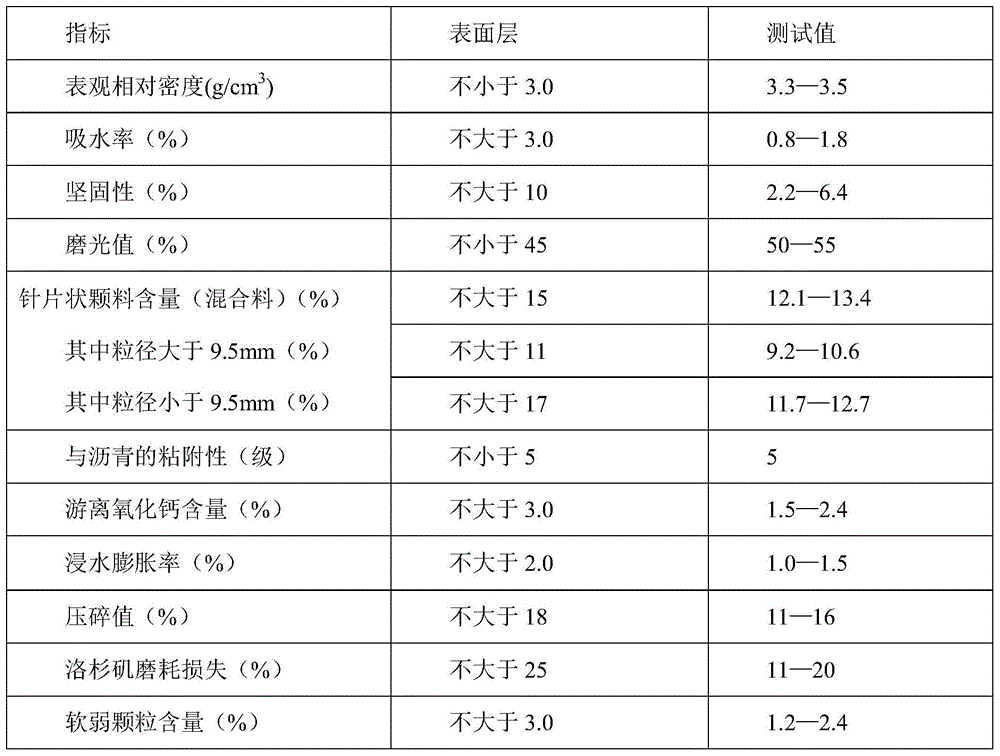

A technology for asphalt concrete and a production method, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of large mud content, not rich in angularity, and large variability of steel slag aggregate specifications, etc. It can achieve the effect of easy breakage, obvious environmental protection benefits, and improved surface cleanliness and surface alkalinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

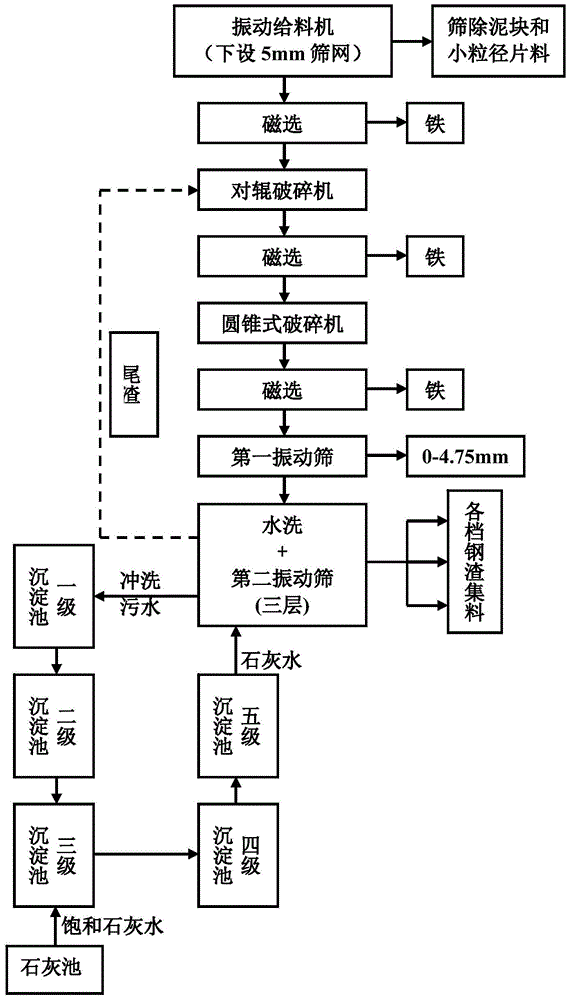

[0028] Feeding: Raw materials enter the vibrating feeder, and pass through the 5mm screen under it to remove mud and small-size flakes;

[0029] First-level magnetic separation: the raw materials screened by the screen pass through the magnetic separation device for first-level magnetic separation, mainly to separate iron and other metals;

[0030] Primary crushing: the material after primary magnetic separation enters the roller crusher for primary crushing;

[0031] Secondary magnetic separation: the materials after the initial crushing are subjected to secondary magnetic separation;

[0032] Fine crushing: The primary crushing and secondary magnetic separation materials enter the cone crusher for fine crushing, and the content of needle-like flake particles of steel slag after crushing is not more than 15%;

[0033] Three-stage magnetic separation: three-stage magnetic separation for crushed materials;

[0034] The above-mentioned three-stage magnetic separation is comple...

Embodiment 2

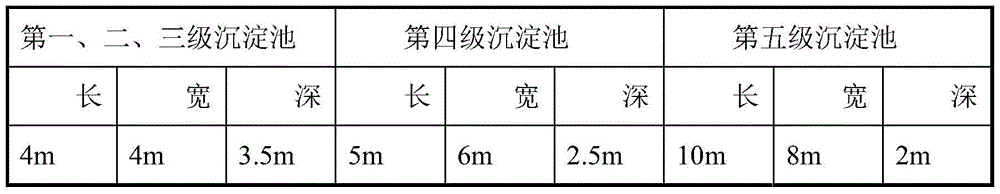

[0049] Take the steel slag aged for one year after hot-splashing treatment in a large iron and steel enterprise in Hubei as raw material, the others are the same as in Example 1, and some parameters of the vibrating screen and belt conveyor used are as follows:

[0050]

[0051] The yield of the obtained product (the sum of aggregates of all grades, excluding the 0-4.75mm part) is about 70%.

Embodiment 3

[0053] Take the steel slag aged for one year after hot-splashing treatment in a large iron and steel enterprise in Hubei as raw material, the others are the same as in Example 1, and some parameters of the vibrating screen and belt conveyor used are as follows:

[0054]

[0055] The yield of the obtained product (the sum of all grades of aggregates, excluding the 0-4.75mm part) is about 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com