Coke-oven gas quench-type methanation reaction device and reaction method thereof

A methanation reactor and reaction device technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of longer process, increased pressure drop, increased number of reactors, etc., to achieve reduced circulation, short process and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

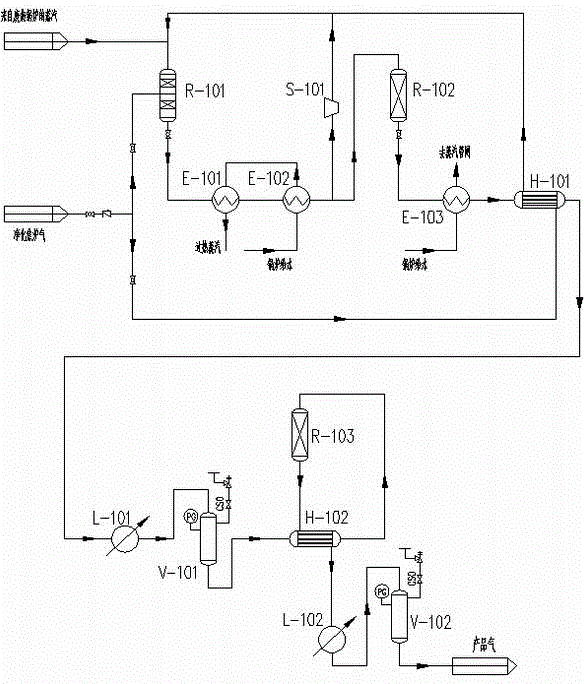

[0021] Purified coke oven gas, its composition (dry basis: %) is H 2 : 57.4; CH 4 : 25.8; CO: 8.2; CO 2 : 1.8; the remainder is an inert gas. Total flow 1000 Nm 3 / h, pressure 2.8 MPa, temperature 42°C. Workflow see figure 1 .

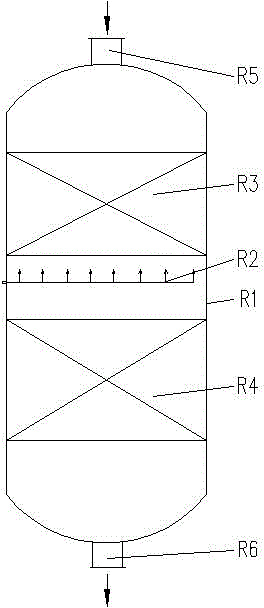

[0022] 1000 Nm 3 / h The coke oven gas is divided into two streams, the flow rate of the first stream is 400Nm 3 / h, heat exchange with the outlet gas of the secondary methanation reactor R-102, the temperature rises to 300°C, and the cycle gas from the cycler S-101 (flow rate is 160Nm 3 / h) mixing, the gas composition after mixing (dry basis: %) is H 2 : 51.8, CH 4 : 34.7, CO: 5.3, CO 2 : 2.1, temperature 280°C. The mixed gas enters the first cold-shock methanation reactor R-101, flows through the first-stage methanation catalyst bed R3, and the methanation reaction occurs, and the temperature of the gas exiting the first-stage bed is 585°C. Coke oven gas provided by a cold shock gas distributor R2 (flow rate 600Nm 3 / h) Mixing in the shock...

Embodiment 2

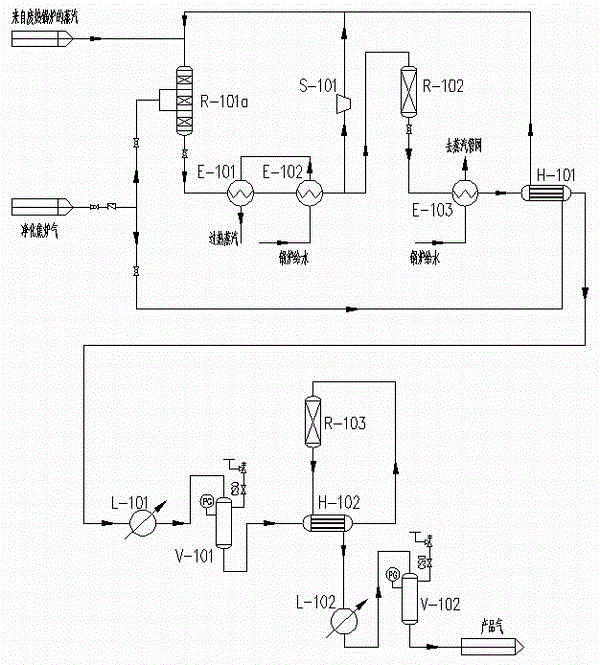

[0025] Purified coke oven gas, its composition (dry basis: %) is: H 2 : 57.4; CH 4 : 25.8; CO: 8.2; CO 2 : 1.8; the remainder is an inert gas. Total flow 1000 Nm 3 / h, pressure 2.8 MPa, temperature 42°C. Workflow see figure 2 .

[0026] 1000 N m 3 / h The coke oven gas is divided into three streams, the flow rate of the first stream is 300Nm 3 / h, heat exchange with the outlet gas of the secondary methanation reactor R-102, the temperature rises to 290 °C, and the cycle gas from the cycle machine S-101 (flow rate is 90Nm 3 / h) mixing, the temperature after mixing is 280°C. The mixed gas enters the second cold-shock methanation reactor R-101a, flows through the first-stage methanation catalyst bed R3, and the methanation reaction occurs, and the temperature of the gas exiting the first-stage methanation catalyst bed R3 is 578°C. This gas is combined with the second coke oven gas (flow rate 300Nm) provided by the first cold shock gas distributor R2 3 / h) Mixing in the ...

Embodiment 3

[0029] Purified coke oven gas, its composition (dry basis: %) is H 2 : 57.4; CH 4 : 25.8; CO: 8.2; CO 2 : 1.8; the remainder is an inert gas. Total flow 1000 Nm 3 / h, pressure 2.8 MPa, temperature 42°C. Workflow see figure 2 .

[0030] 1000 Nm 3 / h The coke oven gas is divided into three streams, the flow rate of the first stream is 200Nm 3 / h, heat exchange with the outlet gas of the secondary methanation reactor R-102, the temperature rises to 290°C, and the cycle gas from the cycler S-101 (flow rate is 200Nm 3 / h) mixing, the temperature after mixing is 280°C. The mixed gas enters the second cold-shock methanation reactor R-101a, flows through the first-stage methanation catalyst bed R3, and the methanation reaction occurs, and the temperature of the gas exiting the first-stage methanation catalyst bed R3 is 518°C. This gas is combined with the second coke oven gas (flow rate 400Nm) provided by the first cold shock gas distributor R2 3 / h) Mixing in the shock zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com