Spaced staggered reverse deflecting flow energy dissipation hydraulic rectifying device and method

A rectification device and staggered technology, which is applied in the field of interval staggered reverse deflection energy dissipation hydraulic rectification devices, can solve the problems of unstable water flow, sediment deposition, etc., and achieve the prevention and control of sediment deposition, increased flow velocity, The effect of increasing the bottom flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

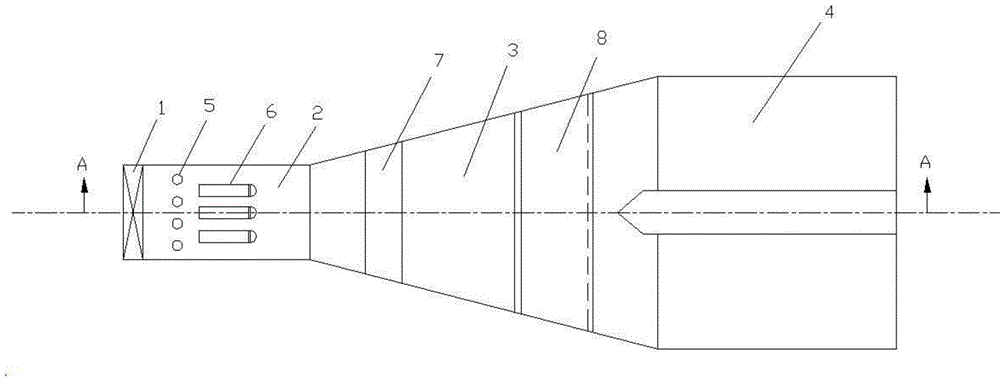

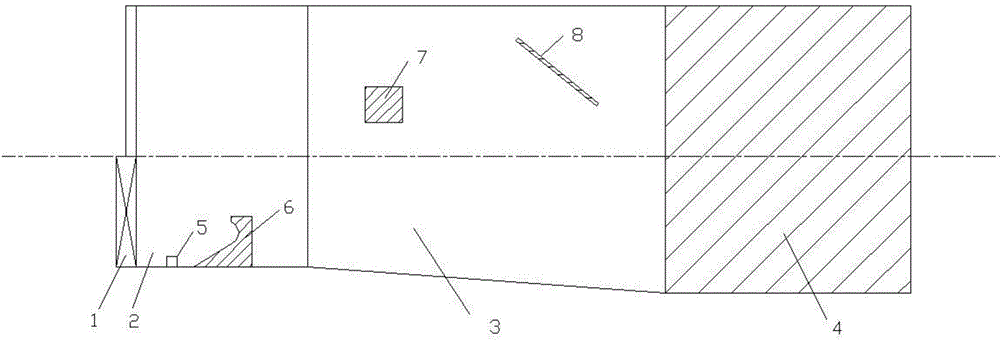

[0031] refer to Figure 1-Figure 2 , a spaced staggered reverse deflected flow energy dissipation hydraulic rectification device, comprising a gate 1, aqueduct 2, a forebay 3, an inlet pool 4, an interval type bottom sill 5, an interval type reverse deflected flow energy dissipation pier 6, rectification Beam 7 and pressure water plate 8.

[0032] The spaced bottom sill 5 is arranged behind the gate 1, and the height of the spaced bottom sill 5 is lower than the opening of the gate 1. The spaced bottom sill 5 is symmetrically distributed on the center line of the aqueduct 2, and the two spaced bottom sills 5 The interval dimension and the quantity of the interval type bottom sill 5 are determined according to the width of the aqueduct 2 . The spaced bottom sill 5 is a cylinder with a circular horizontal section. The spaced reverse deflecting flow energy dissipation pier 6 is arranged symmetrically in a staggered manner with the spaced bottom sill 5 along the centerline of th...

Embodiment 2

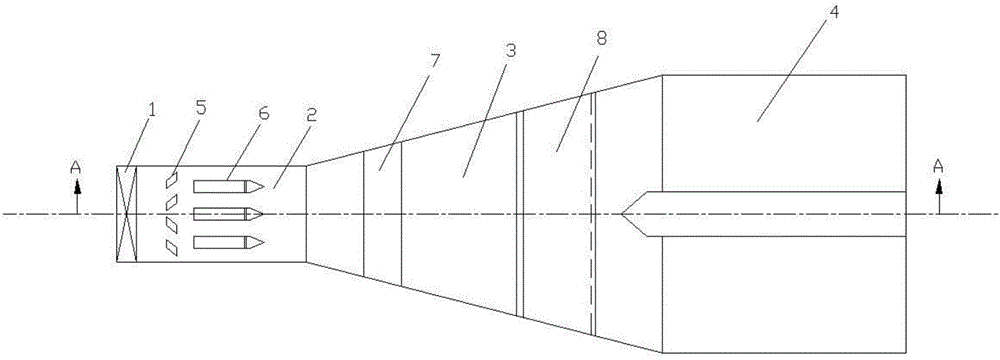

[0040] refer to Figure 3-Figure 4 , a spaced staggered reverse deflected flow energy dissipation hydraulic rectification device, comprising a gate 1, aqueduct 2, a forebay 3, an inlet pool 4, an interval type bottom sill 5, an interval type reverse deflected flow energy dissipation pier 6, rectification Beam 7 and pressure water plate 8.

[0041] The spaced bottom sill 5 is arranged behind the gate 1, and the height of the spaced bottom sill 5 is lower than the opening of the gate 1. The spaced bottom sill 5 is symmetrically distributed on the center line of the aqueduct 2, and the two spaced bottom sills 5 The interval dimension and the quantity of the interval type bottom sill 5 are determined according to the width of the aqueduct 2 . The spaced bottom sill 5 is a quadrangular prism with a parallelogram in horizontal section. The spaced reverse deflecting flow energy dissipation pier 6 is arranged symmetrically in a staggered manner with the spaced bottom sill 5 along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com