Annular float valve core type drain valve

A ring-shaped float and steam trap technology, which is applied to valve details, valve devices, steam traps, etc., to achieve the effects of low failure rate, low manufacturing, assembly and maintenance costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

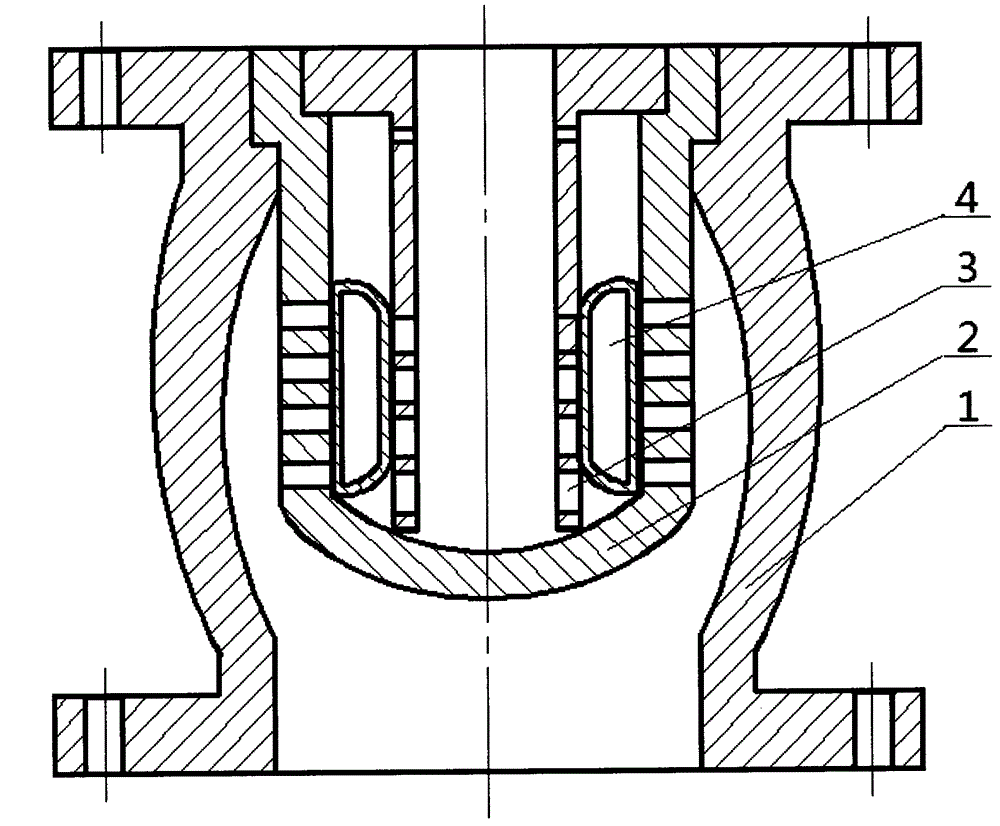

[0014] An annular float spool type steam trap is composed of a valve body 1, a valve seat 2, a downcomer 3, and an annular float spool 4; The upper end is connected with the upper end of the valve seat 2, and the annular float spool 4 is installed between the valve seat 2 and the downcomer 3.

[0015] The above-mentioned annular float spool type steam trap is characterized in that: the valve seat 2 is a blind pipe structure, and the lower half of the pipe wall is circumferentially provided with drainage screen holes.

[0016] The above-mentioned annular float spool type steam trap is characterized in that: the lower half of the downcomer 3 is provided with drainage screen holes in the circumferential direction, and a pair of balance holes are provided in the upper circumferential direction.

[0017] The above-mentioned annular float spool type steam trap is characterized in that: the annular float spool 4 is a hollow annular body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com