Method and device for achieving information collection automation during production process of PCBA (printed circuit board assembly) flow line

A production process and information collection technology, which is applied in the direction of collaborative operation of devices, instruments, manufacturing computing systems, etc., can solve problems such as poor data accuracy, inconsistent information, product quality assessment and control effects in the production process, and achieve monitoring and improvement. The effect of improving quality, improving production efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

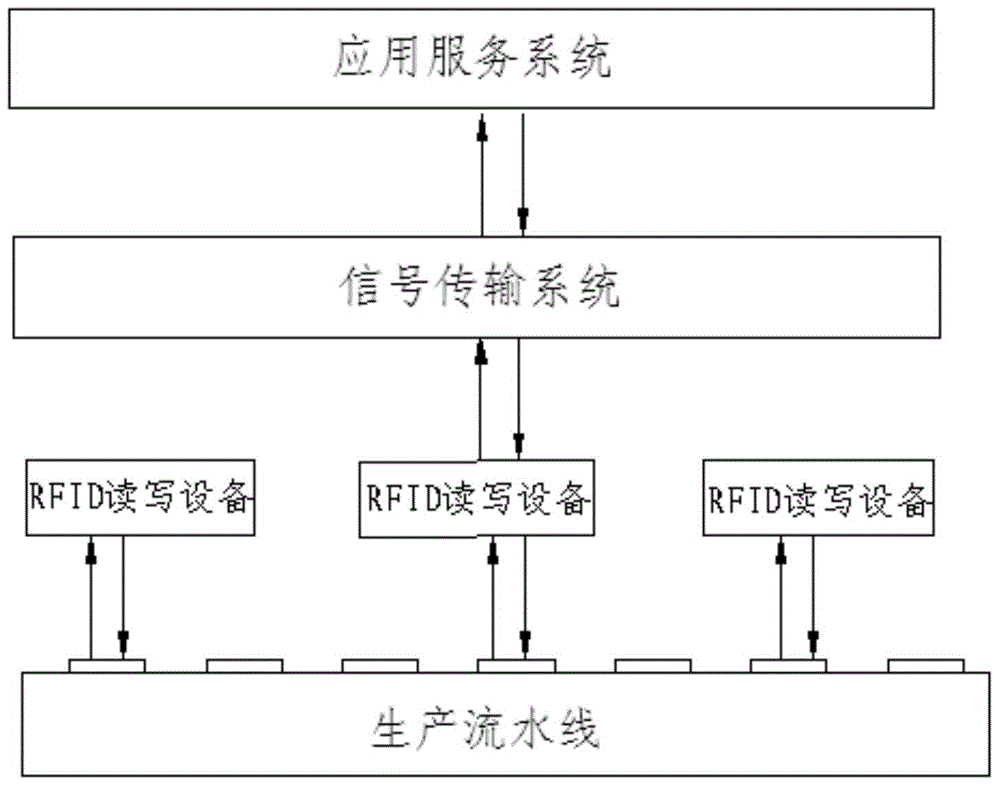

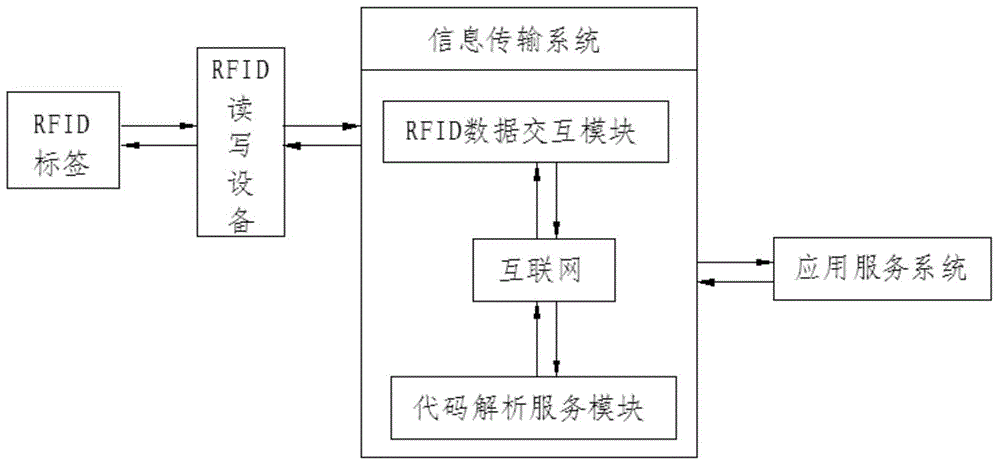

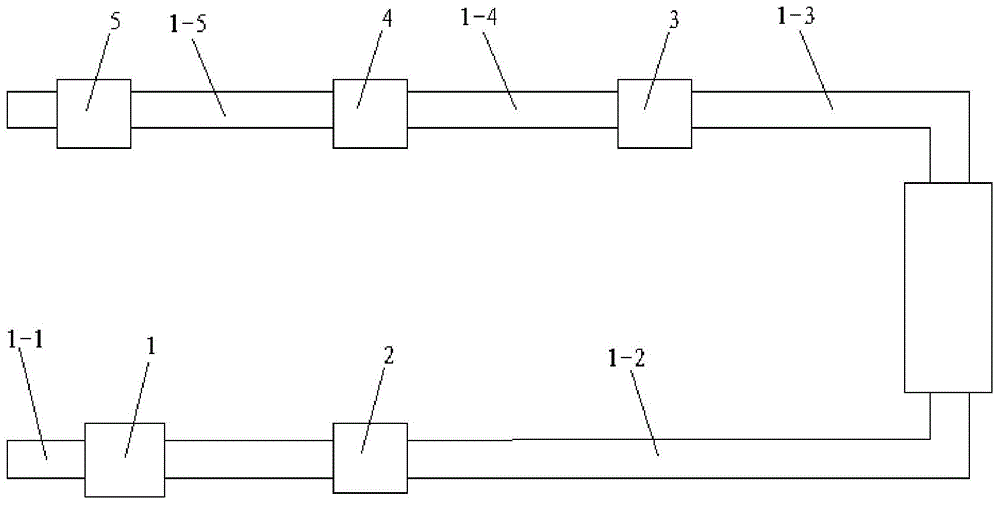

[0048] Such as Figure 1-Figure 2 As shown, the device for realizing information collection automation in the PCBA assembly line production process involved in this embodiment includes several RFID readers 18, RFID data interaction system 19, code analysis system 20, information service system 21, and enterprise information server; The RFID chip is embedded in the product PCB board 17, and the RFID reader 18 is installed in the set position of the PCBA production line 16; the RFID chip is embedded on the home appliance controller PCB board, and the RFID reader 18 collects the product PCB board carried on the conveyor belt 17 RFID chip data, the obtained data is sent to the application service system through the information transmission system for data storage and processing, and the production process data is automatically collected according to the read-write equipment set up in different work stations, and the relevant products generated during the product production process ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com