Preparation method of LED white light diode

A diode and LED chip technology is applied in the field of preparation of LED white light diodes, which can solve the problems of low production efficiency, reduced light yield of phosphors, high equipment and mold costs, and achieves low production input costs, rapid mass production, and products. The effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with the given examples, but not limited thereto.

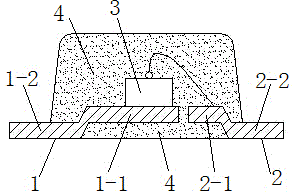

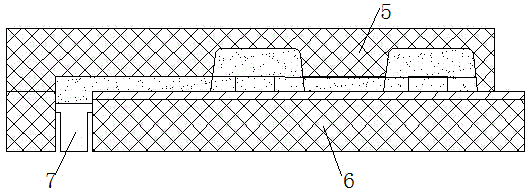

[0018] Such as figure 1 , 2 Shown, a kind of preparation method of LED white light diode, described LED white light diode comprises first lead 1, second lead 2, blue LED chip 3 and epoxy resin adhesive layer 4 containing yellow fluorescent powder, and described first The lead 1 has a first patch base island 1-1 and a first pin 1-2 integrated with each other, and the second lead 2 has a second patch base island 2-1 and a second pin 2- 2. The blue LED chip 3 is mounted on the first SMD base island 1-1 and electrically connected to the first SMD base island 1-1, and the surface of the blue LED chip 3 is connected to the second SMD base island. The island 2-1 is electrically connected, and the first patch base island 1-1, the second patch base island 2-1 and the blue LED chip 3 are covered with an epoxy resin glue layer 4 containing yellow phosphor powder Inside; and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com