Polymer composite solid electrolyte and preparation method thereof

A technology of solid electrolyte and composite materials, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of low ion conductivity and mechanical properties, large quantities, etc., achieve superior performance, reduce production costs, and avoid organic solvents The effect of the release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

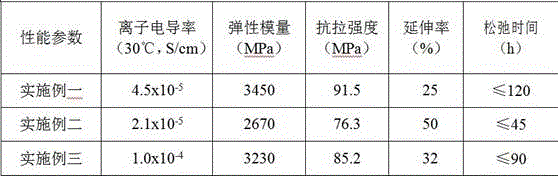

Examples

Embodiment 1

[0029] In this example, the preparation method of the polymer composite solid electrolyte is based on the aqueous solution casting method, and the steps are as follows:

[0030] a. Pour 600 parts of cold water into the reaction kettle, start the mixer, add 60 parts of polyvinyl alcohol with an alcoholysis degree of 88%, slowly raise the temperature to 90°C, and mix mechanically for 2 hours to obtain a uniform solution;

[0031] b. Cool down to 50°C, add 30 parts of lithium perchlorate, and stir for 2.5 hours to completely dissolve it in the aqueous solution of polyvinyl alcohol;

[0032] c. Continue to cool down to 40°C, slowly add 25 parts of an aqueous dispersion of silica nanoparticles (20% solid content), and mix for 3 hours under the joint action of ultrasonic waves and mechanical stirring;

[0033] d. Add 5 parts of water-dispersible polymeric isocyanate dropwise and stir for 15-30 minutes;

[0034] e. The above solution was poured into a polytetrafluoroethylene co...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, especially in that:

[0038] In this embodiment, the preparation method of polymer composite solid electrolyte, the steps are as follows:

[0039] a. Pour 600 parts of cold water into the reaction kettle, start the mixer, add 55 parts of polyvinyl acetate-ethylene emulsion (VAE) rubber powder, slowly raise the temperature to 60°C, and mix mechanically for 2 hours to obtain a uniform solution;

[0040] b. Cool down to 50°C, add 35 parts of lithium carbonate, and stir for 3 hours to completely dissolve in the VAE solution;

[0041] c. Continue to cool down to 30-40°C, slowly add 30 parts of nano-calcium carbonate aqueous dispersion (with a solid content of 20%), and mix for 2.5 hours under the joint action of ultrasonic waves and mechanical stirring;

[0042] d. Add 4 parts of water-dispersible polymeric polyisocyanate dropwise and stir for 15-30 minutes;

[0043] e. This step is identical with embodiment one; ...

Embodiment 3

[0046] This embodiment is basically the same as the previous embodiment, and the special features are:

[0047] In this embodiment, the preparation method of polymer composite solid electrolyte, the steps are as follows:

[0048] a. Pour 600 parts of cold water into the reaction kettle, start the mixer, add 50 parts of polyvinyl alcohol with an alcoholysis degree of 99% and 10 parts of carboxymethyl cellulose, slowly raise the temperature to 95°C, and mix mechanically for 2 hours to obtain a uniform solution;

[0049] b. Cool down to 50°C, add 30 parts of lithium sulfate, and stir for 2.5 hours to completely dissolve in the mixed aqueous solution of polyvinyl alcohol and carboxymethyl cellulose;

[0050] c. Continue to cool down to 30-40°C, slowly add 20 parts of nano-titanium dioxide aqueous dispersion (with a solid content of 20%), and mix for 3 hours under the joint action of ultrasonic waves and mechanical stirring;

[0051] d. Add 6 parts of high-functionality polyis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com