Bilateral linear motor with primary electric excitation series magnetic circuit

A series of magnetic circuit, linear motor technology, applied in electrical components, electromechanical devices, electric components and other directions, can solve the problems of increase, material waste cost, large proportion of secondary yoke iron core, etc., to improve power density, increase load ability, the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

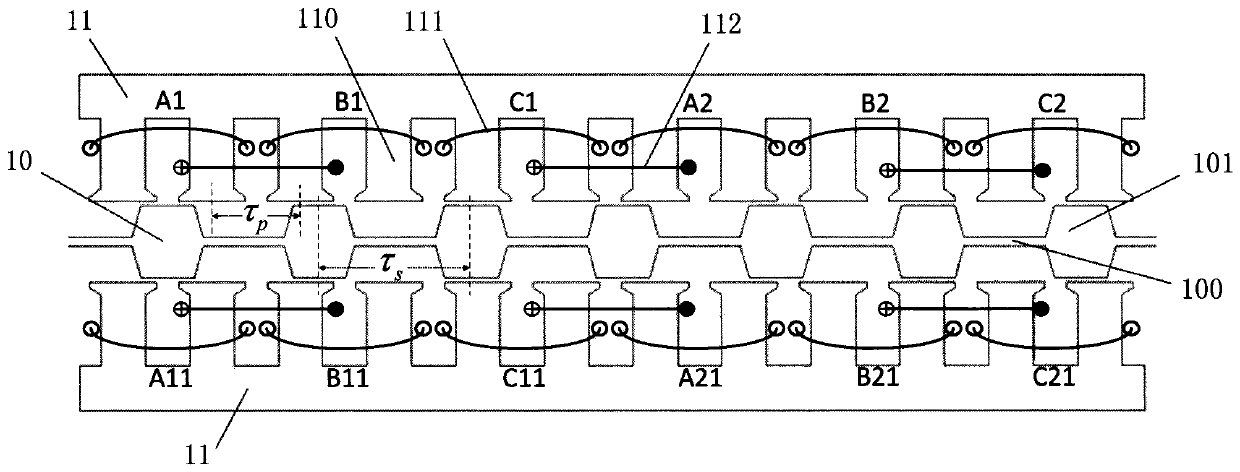

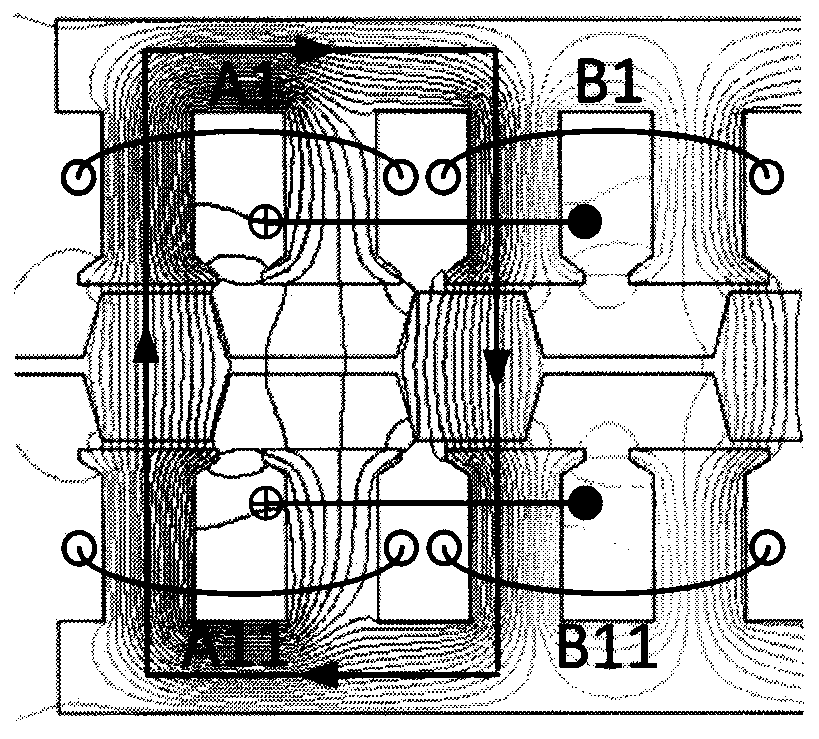

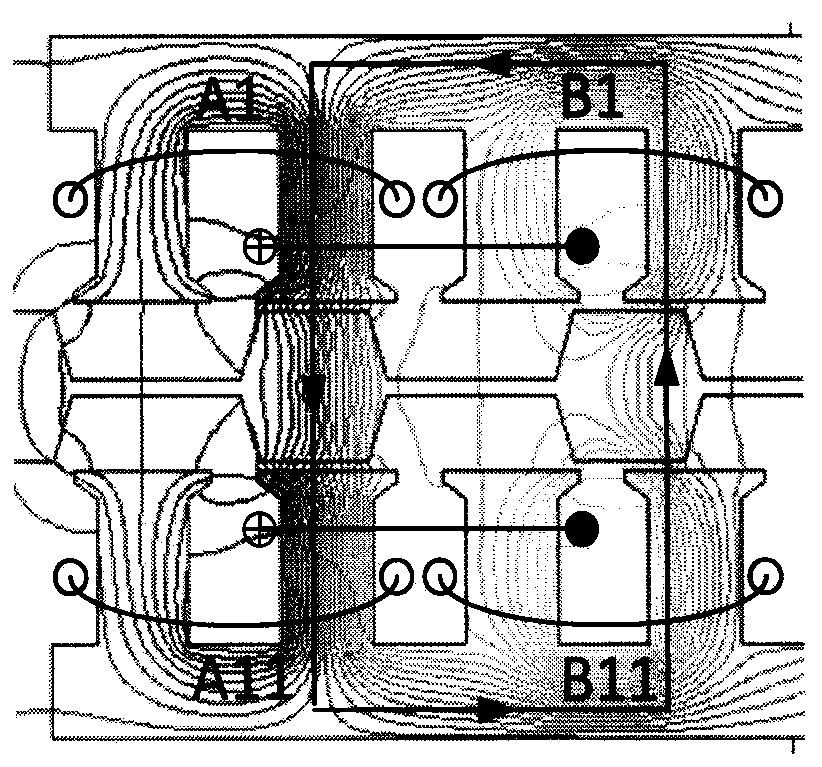

[0030] see figure 1, the primary electric excitation series magnetic circuit bilateral linear motor of the present invention comprises a bilateral primary 11 and a secondary 10, the primary 11 and the secondary 10 are both magnetically permeable materials with an air gap between them, and the primary 11 is provided with a magnetically permeable tooth 110 , the concentrated armature windings 111 and the concentrated excitation windings 112 are arranged alternately on the magnetically permeable teeth 110 . In the motor of this embodiment, m=3, k=1, n=1, wherein, m is the phase number of the motor, n and k are positive integers, n is the number of motor units, and k is the unilateral primary in each motor unit The number of concentrated armature winding pairs connected in series in any phase of the armature winding. That is, the motor is a three-phase motor with three phases A, B, and C, and includes n=1 motor units, and each motor unit has k=1 pairs of concentrated armature win...

Embodiment 2

[0038] Figure 4 It is also a bilateral linear motor with primary electric excitation series magnetic circuit. In this embodiment, k=1, n=2, m=3, that is, the motor is a three-phase motor, including 2 motor units, each motor unit has k=1 pair of centralized armature winding. The difference between this embodiment and Embodiment 1 is that n=2, that is, it consists of two motors of Embodiment 1. Therefore, this motor also has the characteristics of the motor of embodiment 1. n=2 motor units can be controlled individually, or connected in series as a motor control.

Embodiment 3

[0040] Figure 5 Also for a bilateral primary electric excitation secondary yokeless linear motor. In this embodiment, k=2, n=1, m=3, that is, the motor is a three-phase motor, including 1 motor unit, and there are k=2 pairs of concentrated armature windings in each unilateral primary, so a single The number of side primary 11 magnetic conducting teeth 110 is Ns=4*m*k*n=24, and the number of magnetic conducting teeth 110 is successively provided with concentrated armature winding 111 is 2*m*k*n=12, from Starting from the first magnetically conductive teeth 110, every two magnetically conductive teeth 110 are covered with a concentrated armature winding 111, and adjacent concentrated armature windings 111 share one slot; the remaining 2*m*k*n=12 slots Set m*k*n=6 concentrated excitation windings 112 in sequence and each concentrated excitation winding 112 is covered with two magnetically conductive teeth, that is, starting from the second magnetically conductive tooth 110, eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com