Polyester film

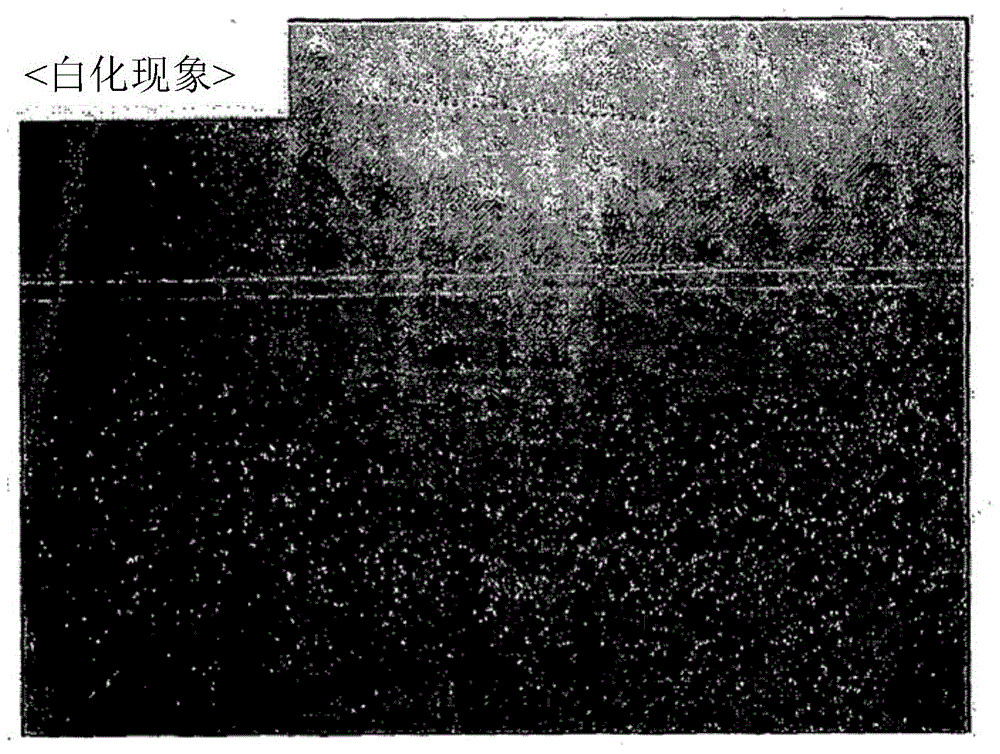

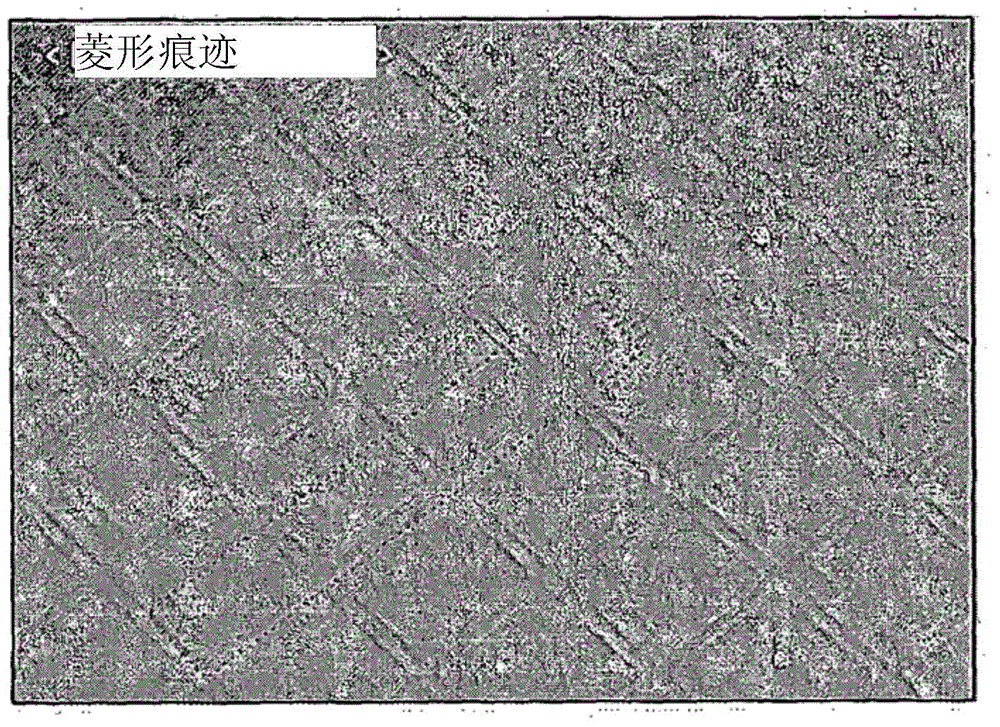

A technology of polyester film and polyester base film, which is applied in the field of polyester film, can solve the problem of not being able to completely block the leakage of oligomers, and achieve the effect of avoiding the increase of haze and blocking the leakage of oligomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0149] 1) Preparation of water dispersion resin composition 1

[0150] 16% by weight of KLX-007 binder (TAKAMATSU Corp., Japan, water-dispersed resin composition with a solid content of 25%), 0.3% by weight of silicone-based wetting agent (Dow Corning Corp., polyester- Siloxane copolymer, Q2-5212), and 0.3% by weight of colloidal silicon particles with an average particle size of 140 nm were added to water and stirred for 2 hours to obtain a water-dispersed resin composition 1 with a total solid content of 4.6% by weight.

[0151] In the KLX-007 adhesive, the solid content weight ratio (A:B) of the acrylic resin A and the water-dispersed polyester-based resin B obtained by copolymerizing the glycidyl group-containing free-radically polymerizable unsaturated monomer is 50 :50,

[0152] The acrylic resin contains a glycidyl group-containing radically polymerizable unsaturated monomer as a comonomer in an amount of 50 mol% based on the total monomer components, and

[0153] The...

example 2

[0158] 1) Preparation of water dispersion resin composition 2

[0159] 16% by weight of the KLX-007 adhesive (TAKAMATSU Corp., Japan, a water-dispersed resin composition with a solid content of 25%), 0.4% by weight (10 parts by weight, based on the solid content of the adhesive) A compound represented by the following chemical formula 3, 0.3% by weight of a silicone-based wetting agent (Dow Corning Corp., polyester-siloxane copolymer, Q2-5212), and 0.3% by weight of a colloid having an average particle size of 140 nm The silicon particles were added to water and stirred for 2 hours, thereby obtaining a water-dispersed resin composition 2 having a total solid content of 4.6% by weight.

[0160] [chemical formula 3]

[0161]

[0162] 2) Preparation of oligomer retarded polyester film

[0163] After the dehydrated polyethylene terephthalate chips were put into the extruder and melted and extruded, the temperature was rapidly cooled and hardened using a casting drum with a su...

example 7

[0186] 1) Preparation of water dispersion resin composition 3

[0187] As the binder, an acrylic resin A copolymerized with a glycidyl group-containing radically polymerizable unsaturated monomer and a water-dispersible polyester-based resin B with a solid content weight ratio (A:B) of 40:60 were used. adhesive.

[0188] The acrylic resin A which copolymerized 60 mol% of glycidyl acrylate and 40 mol% of vinyl propionate and whose weight average molecular weight was 35000 was used.

[0189] Water-dispersible polyester-based resin B is an acid component (content of 50 mole %) using sulfoterephthalic acid (15 mole %) and terephthalic acid (85 mole %) and diethylene glycol A resin having a weight-average molecular weight of 14,000 obtained by polymerizing a diol component (50 mol %) of alcohol (50 mol %) and ethylene glycol (50 mol %).

[0190] A total solids content of 0.8 wt% was prepared by adding 0.5 wt% (solids) binder and 0.3 wt% silicone-based wetting agent (BYK 348, BYK ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com