Acoustic sensor with diaphragm made of fiber composite material

A technology of fiber composite materials and acoustic sensors, applied in the field of acoustic sensors, to achieve the effects of low manufacturing cost, low material cost, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

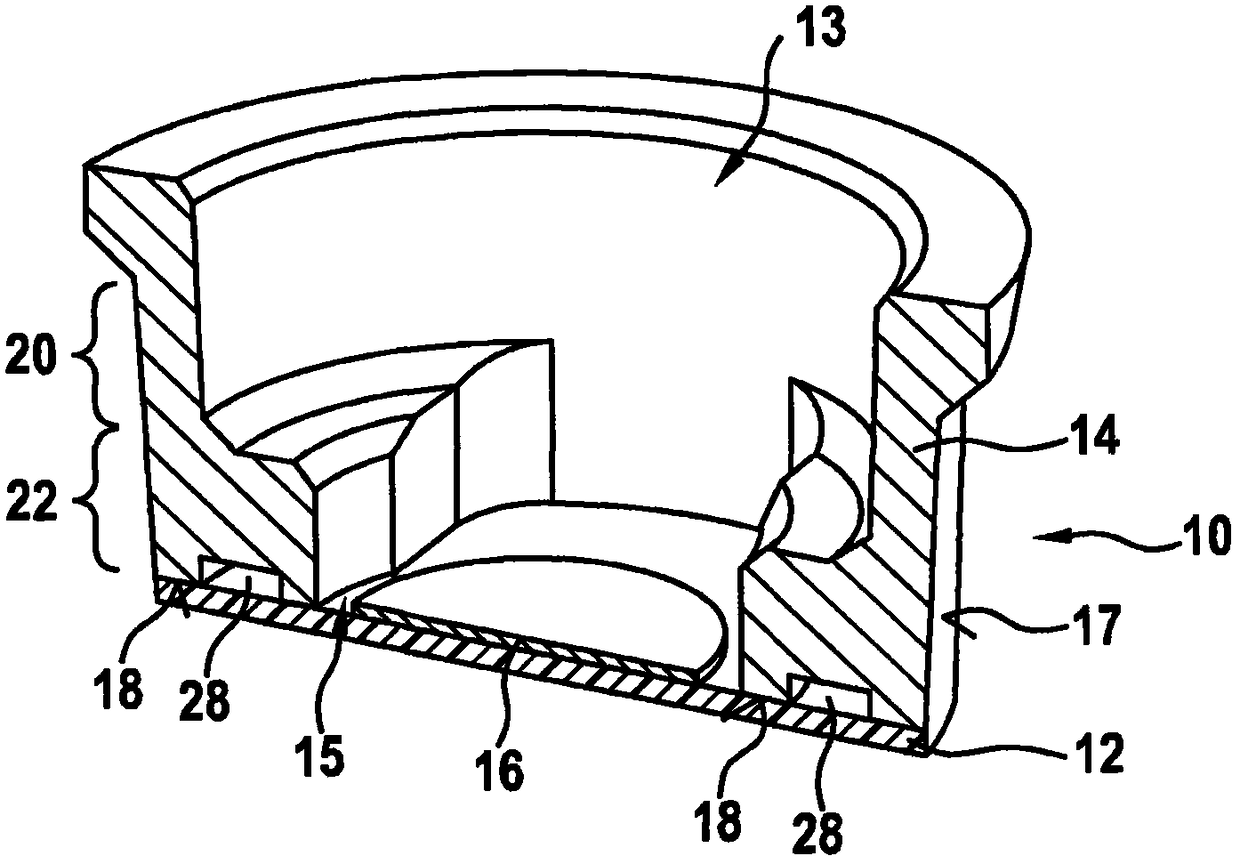

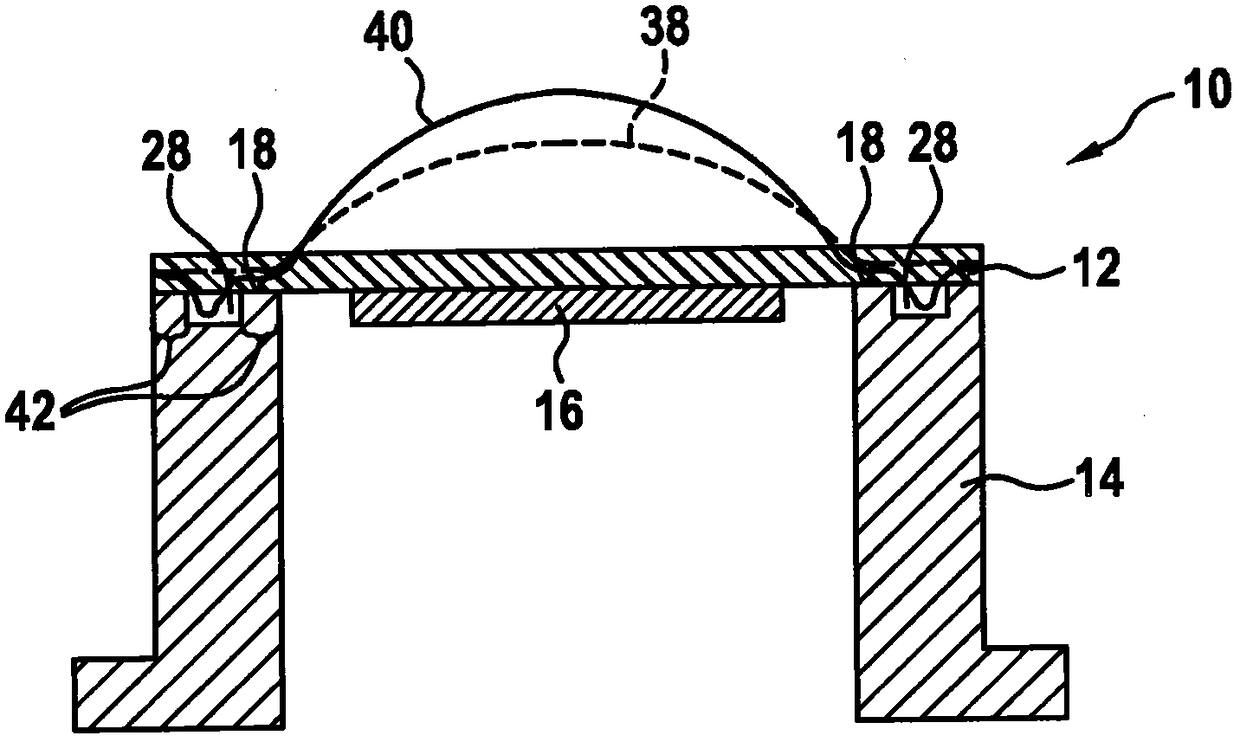

[0040] figure 1 The structure of an acoustic sensor 10 , which is designed as a pot transducer, is schematically shown. The acoustic sensor comprises a membrane 12 which is produced from a fiber composite material, for example carbon fiber reinforced plastic. Membrane 12 is connected to piezoelectric actuator 16 , which transmits the electromechanical interaction of acoustic sensor 10 as a transducer element. Furthermore, piezo actuators 16 are connected via openings 13 to electronic adjustment and control elements, which are in figure 1 not shown in

[0041] In order to form the pot converter 10 , the sensor housing 14 is formed as a hollow body which is open at both end faces 13 , 15 . Here, an end face 15 of the hollow body 14 is connected to the membrane 12 . For example, the membrane 12 can be glued to the bearing surface 18 of the sensor housing or of the hollow body 14 . Furthermore, the surrounding side wall 17 of the sensor housing 14 includes two wall sections 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com