Flour milling apparatus integrating dosing, stirring and kneading

A kind of flour and integrated technology, which is applied to the structural parts of mixing/kneading machinery, mixing/kneading with vertical installation tools, etc., which can solve the problems that cannot be completed independently, the artificial muscle dough hammer and the lifting shovel cooperate incorrectly, and knead dough Problems such as strong movement, to achieve the effect of safe and reliable equipment work, not easy to cooperate with mistakes, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

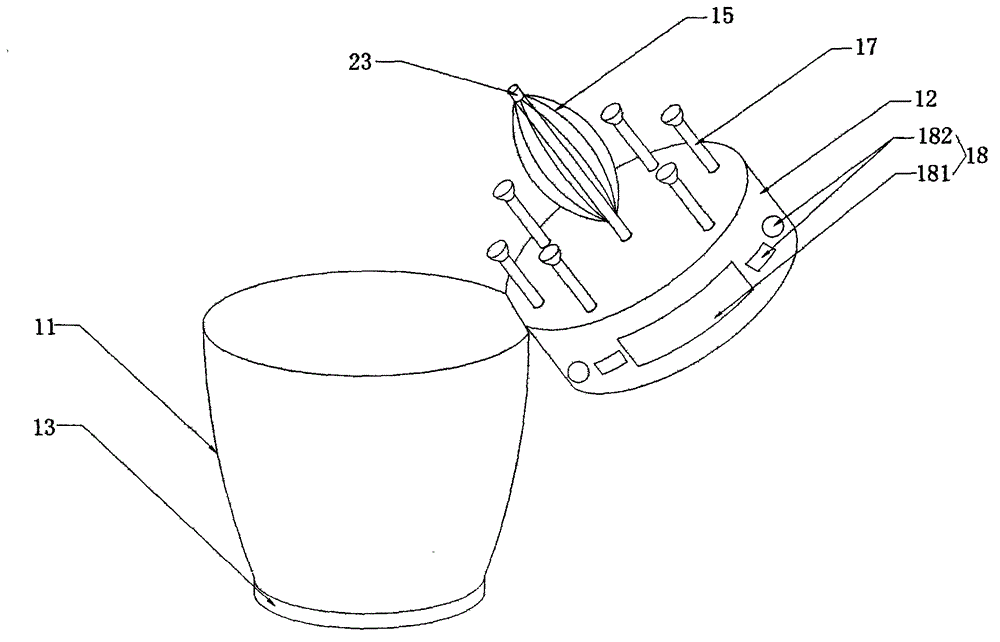

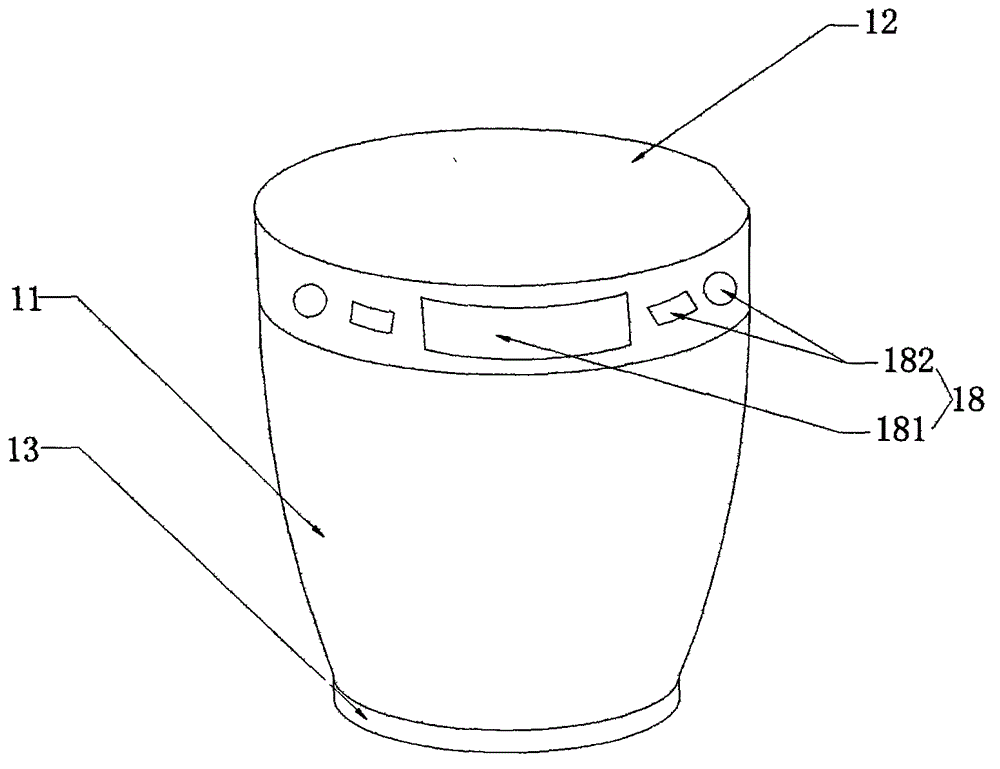

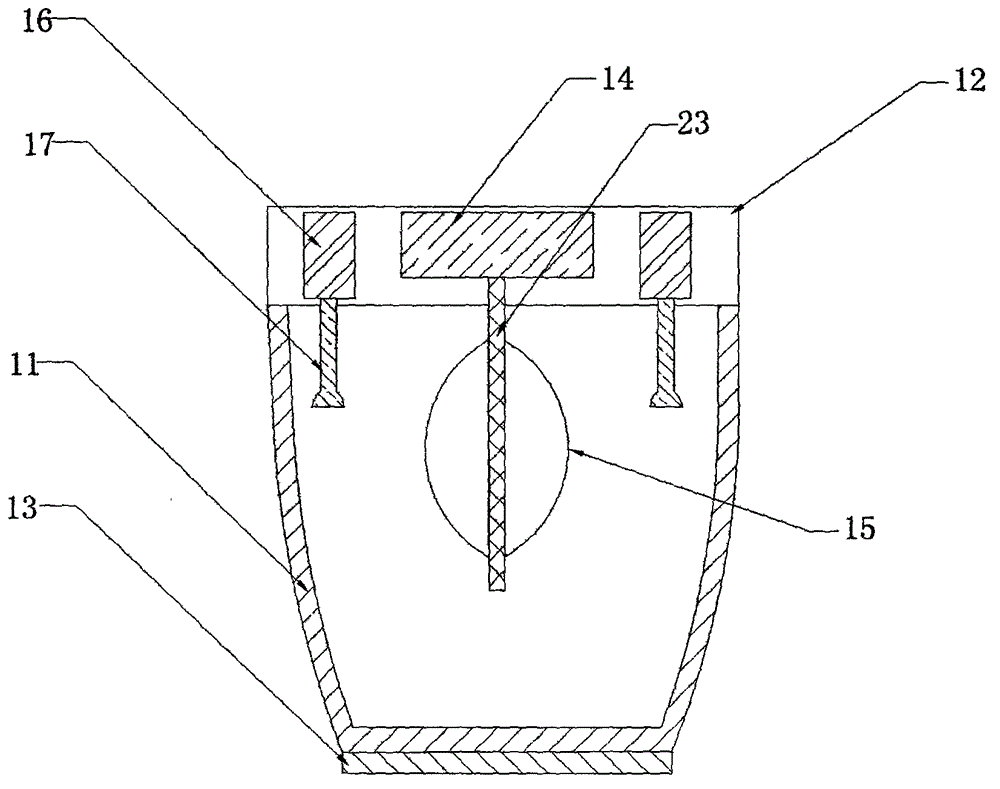

[0031] refer to Figure 1-3 , the flour processing equipment integrating batching, stirring and dough kneading provided by the present invention includes a mixing barrel body 11, a mixing barrel cover 12, an electronic scale 13, a stirring motor 14, a stirring impeller 15, a plurality of electric cylinders 16, a plurality of Kneading dough hammer 17 and control unit 18; mixing bucket cover 12 is hinged with one side of mixing bucket body 11; mixing bucket cover 12 is provided with accommodating cavity, stirring motor 14 and electric cylinder 16 are all fixed in the accommodating cavity; stirring The motor 14 is fixed at the center of the accommodating cavity, the stirring motor 14 is connected to a rotating shaft 23, and the stirring impeller 15 is fixed on the rotating shaft 23; a plurality of electric cylinders 16 are evenly arranged around the stirring motor 14, and the output shaft of the electric cylinder 16 is connected to a kneading hammer 17; the electronic scale 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com