Endoscope bending mechanism free of rivet connection

A bending mechanism and endoscope technology, applied in endoscopy, medical science, surgery, etc., can solve the problems of difficult to guarantee accuracy, high production cost, complicated manufacturing process, etc., and achieve simplified processing and assembly processes and improved accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

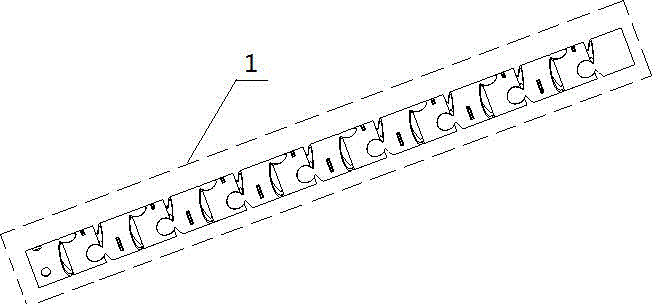

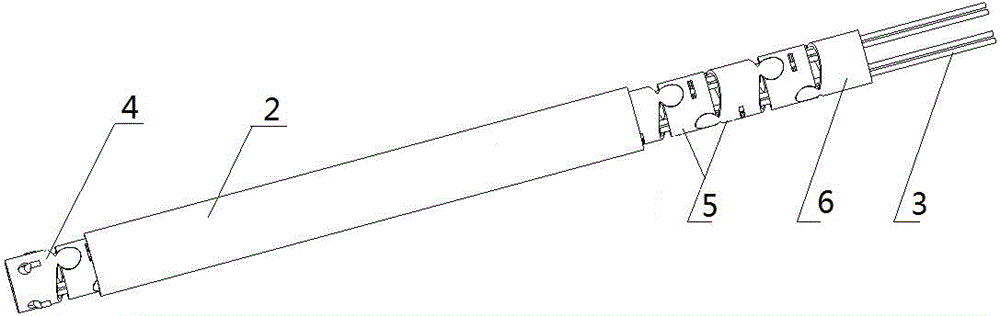

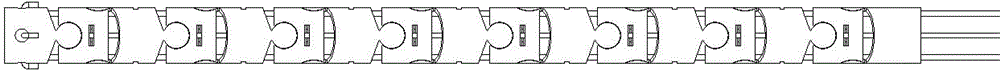

[0024] Such as Figure 1-10 As shown, it is a four-way bending mechanism; the endoscope bending mechanism includes a main frame 1, a braided mesh and a rubber coating 2, and a traction wire 3. The main frame 1 is covered with a layer of braided mesh and rubber coating 2, and the main frame 1 is pierced and connected with several pulling wires 3 to form a rivet-free endoscope bending mechanism as a whole.

[0025] Among them, the main body frame 1 is composed of several connecting rings cut from a thin-walled circular tube. The connecting rings include front-end rings 4 at both ends, rear-end rings 6 and several extension rings 5 in the middle; The hole 7, the right end of the front end ring 4 distributes two circular connecting ears 8 symmetrically along the radial direction, the right end surface of the front end ring 4 has a joint surface 9 that fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com