Air sterilization and disinfection method and system

An air sterilization and air technology, applied in the direction of disinfection, deodorization, etc., can solve the problems of ozone generation, harmful substances, large energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

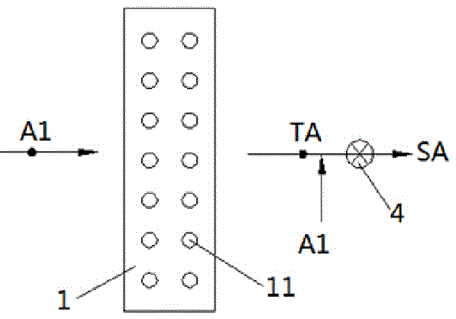

[0024] Such as figure 1 As shown, an air sterilization and disinfection system is composed of a thermal energy device 1 with cooling or heating functions, a fan 4 and pipelines. The thermal energy device 1 is connected to the fan 4 through pipelines; the thermal energy device 1 includes elements 11 . The element 11 can be a heating element or a cooling element, and the heating element is selected from an electric heating element, or a water heating element, a steam heating element, a refrigerant heating element (such as Freon, etc.), an air heating element or a flue gas heating element , the refrigeration element is selected from water refrigeration elements, cold fluid refrigeration elements (such as ethylene glycol, etc.), refrigerant refrigeration elements (such as Freon, etc.).

[0025] The sterilization and disinfection process of this system is as follows: the air A1 from a certain space passes through the thermal energy device 1 and is heated or cooled to become TA, bac...

Embodiment 2

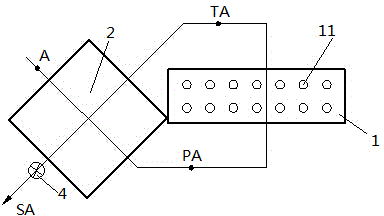

[0030] Such as figure 2 As shown, an air sterilization and disinfection system is characterized in that the system is composed of a heat energy device 1 with refrigeration or heating, a heat recovery device 2, a fan 4 and pipelines, and the heat recovery device 2 includes alternately arranged air intake passages and The air outlet channel, the air intake channel, the thermal energy device 1, the air outlet channel, and the fan 4 are connected in turn through pipelines; the thermal energy device 1 includes an element 11, and the element 11 can be a heating element or a cooling element, and the heating element is selected from Electric heating element, or water heating element, steam heating element, refrigerant heating element (such as freon, etc.), air heating element or flue gas heating element, and the cooling element is selected from water cooling element, cold fluid cooling element (such as ethylene glycol etc.), refrigerant refrigeration components (such as Freon, etc.)....

Embodiment 3

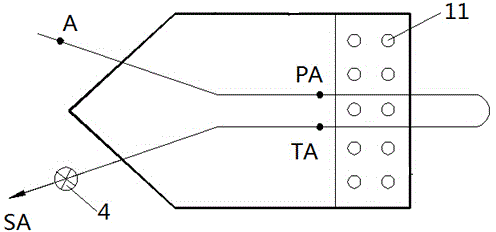

[0036] Such as image 3 with 4 As shown, the thermal energy device 1 and the heat recovery device 2 are integrated, that is, the system is directly composed of elements 11, a plurality of heat exchange walls 31 and fans, and two adjacent heat exchange walls 31 form an air intake channel or The air outlet channel, the air inlet channel or the air outlet channel are arranged alternately; the air inlet channel, the element 11, the air outlet channel, and the fan are connected in sequence, and the element 11 can be a heating element or a cooling element, and the heating element is selected from an electric heating element, or is Water heating element, steam heating element, refrigerant heating element (such as freon, etc.), air heating element or flue gas heating element, and the cooling element is selected from water cooling element, cold fluid cooling element (such as ethylene glycol, etc.), refrigerant cooling Components (such as Freon, etc.).

[0037] Such as Figure 5 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com