An internal high pressure forming system for pipe fittings

A technology for internal high pressure forming and pipe fittings, applied in the field of high pressure forming systems for pipe fittings, can solve the problems of low quality and precision of pipe fittings, high equipment pressure holding requirements, easy deformation of molds, etc., and achieves improved quality, high fatigue strength, and thinning. volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

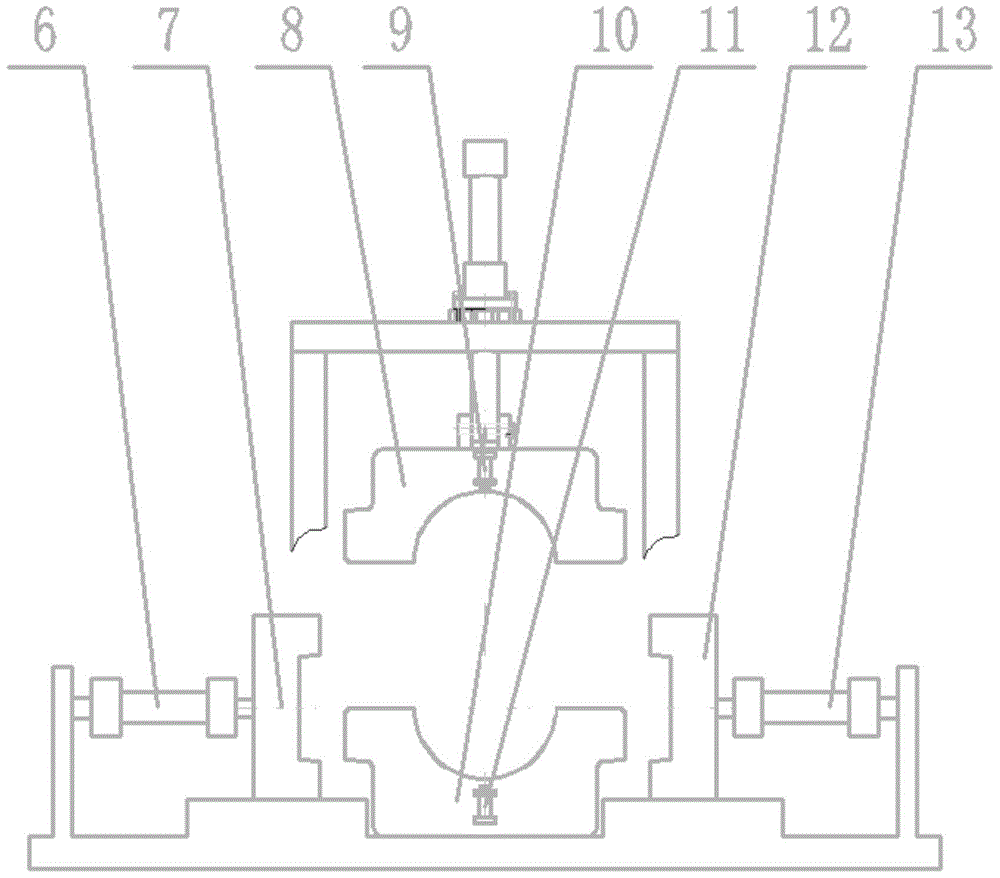

[0014] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

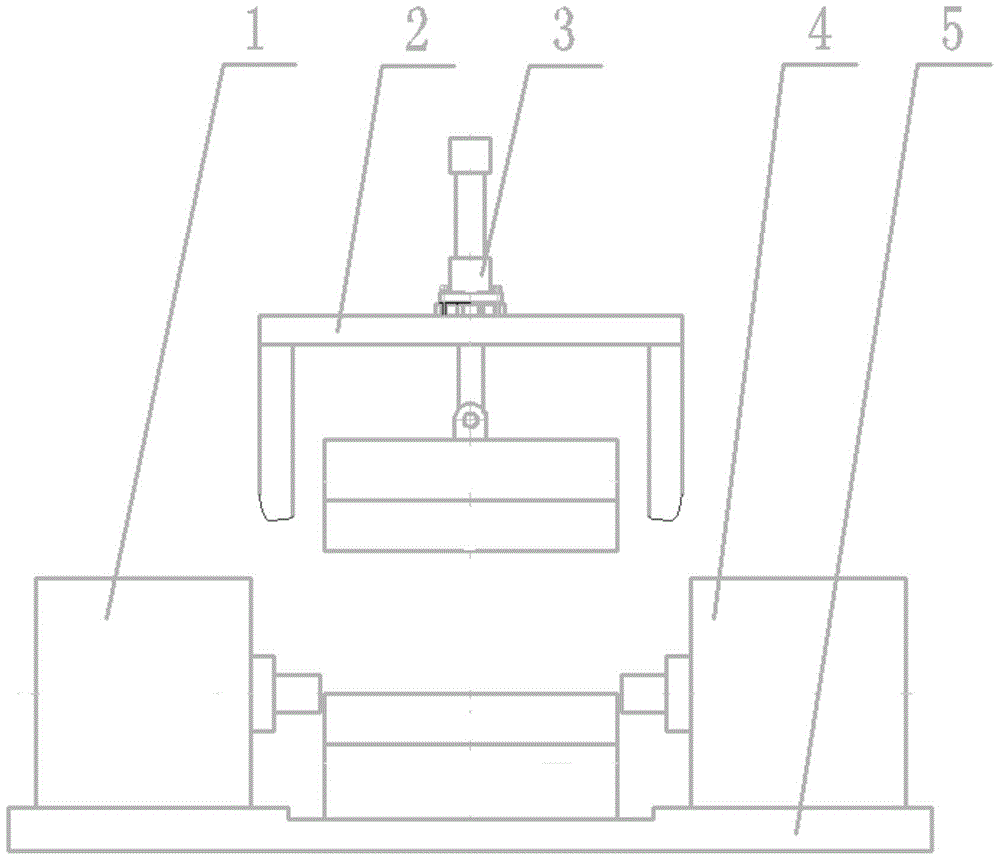

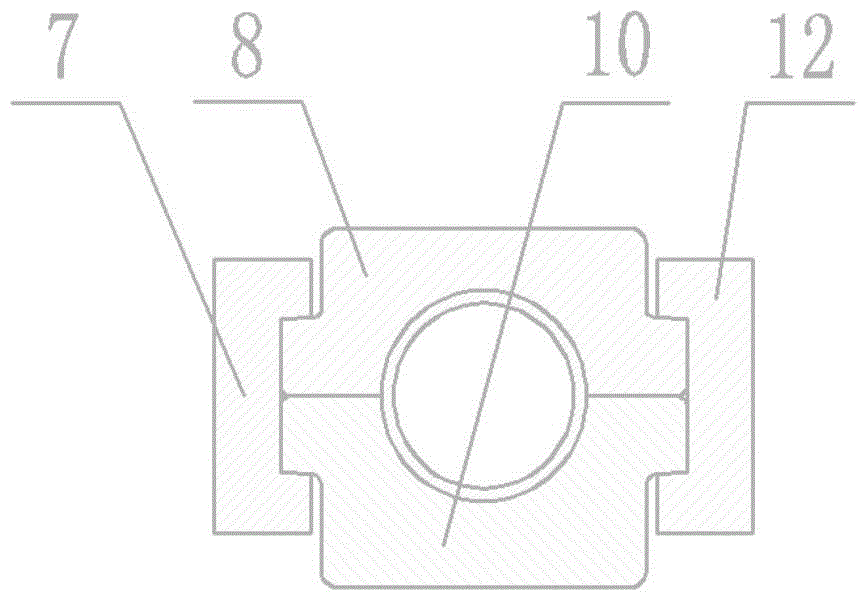

[0015] refer to figure 1 and figure 2 , a high-pressure forming system for pipe fittings, including a frame 2 and a lower platform 5, characterized in that the frame 2 is fixed on the lower platform 5, the lifting cylinder 3 is fixed on the frame 2, and is connected with the upper mold 8, because The function of the lifting cylinder 3 is to lift the upper mold 8, and its force only needs to overcome the dead weight of the upper mold 8, so the quality and type of the lifting cylinder 3 are relatively small; The oil cylinder 9 is used to separate the formed part from the upper mold 8 after forming, so as to prevent the formed pipe from being dropped and damaged when the upper mold 8 is lifted due to the deformation of the tube blank and the close fit of the upper mold 8 during the forming process. The locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com