Punching die

A technology of stamping dies and dies, applied in the field of dies, can solve problems such as worker fatigue, reduce die life, and large vibration of punching machines, and achieve the effects of less vibration of machine tools, prolonging service life, and reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

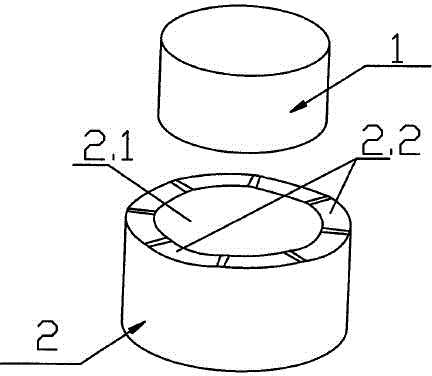

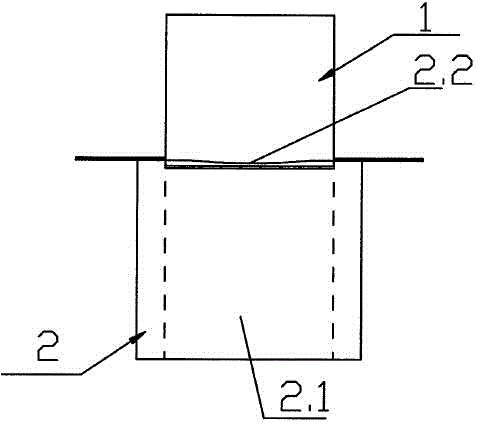

[0015] Such as figure 1 , 2 As shown, the present invention discloses a stamping die, including a punch 1 and a die 2, the die 2 is cylindrical, the inner cavity of the die 2 is the stroke cavity 2.1 of the punch 1, the punch 1 and the die 2 The shape and size of the inner cavity match, the upper end surface of the die 2 is a raw material placement platform, the upper end surface of the die 2 is provided with a feeding mechanism, and the feeding mechanism is set horizontally with the placement platform, and the shear surface at the upper end surface of the die 2 is 2.2 into a curved shape.

[0016] The longitudinal section of the shearing surface 2.2 is corrugated. The shearing surface of the die on the existing stamping die is a plane. After the material is placed on it, when stamping, all surfaces of the material are stressed, please punch it off at the same time, so the requirements for the punching machine are high. And the shearing surface 2.2 of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com