A powerful five-axis linkage milling head in the form of ab pendulum

A five-axis linkage and B-axis technology, applied in the direction of drive devices, milling machine equipment, milling machine equipment details, etc., can solve the problems that restrict the development speed of the machine tool industry to high-end CNC products, the development of functional components lags behind, and the accuracy and rigidity are not enough. Achieve the effects of reducing adverse effects, compact structure, and high running precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

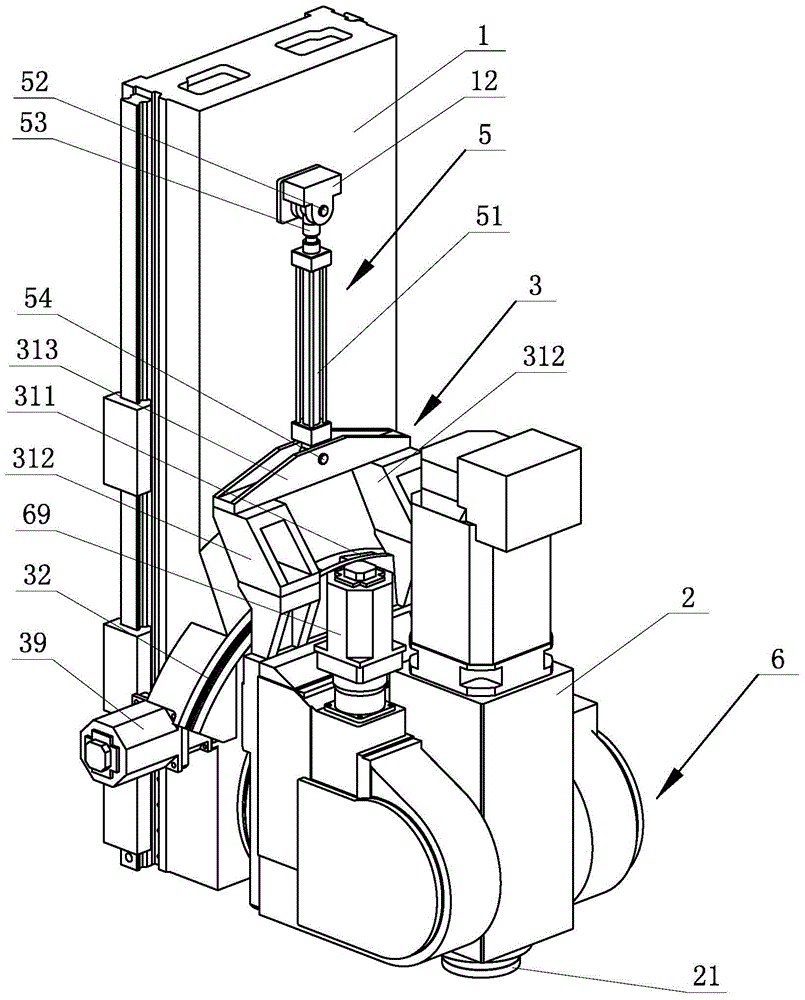

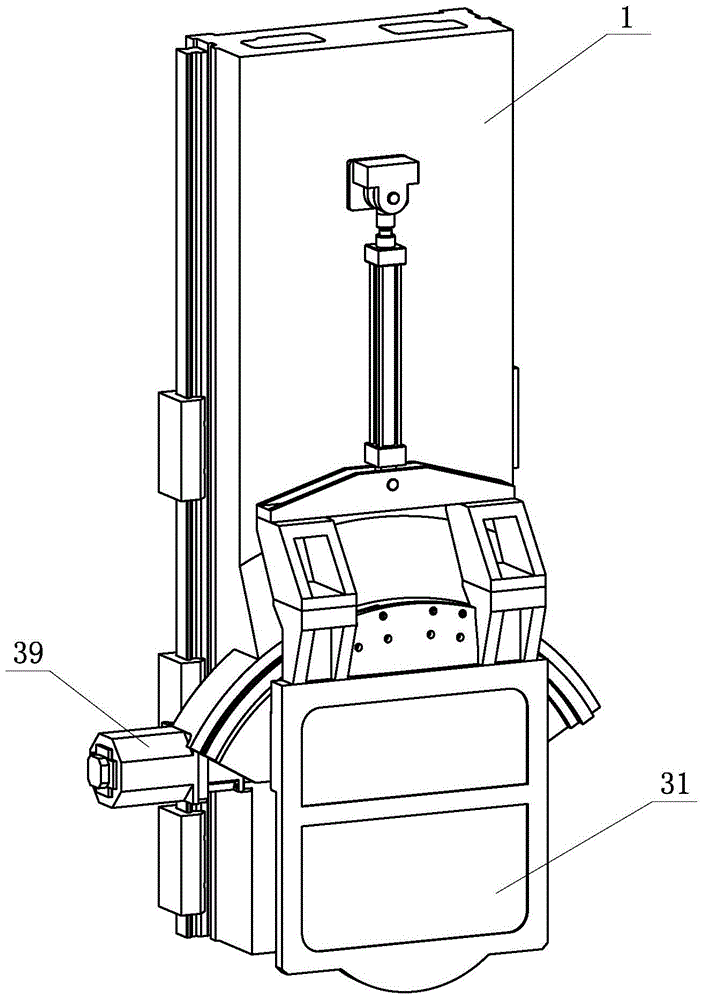

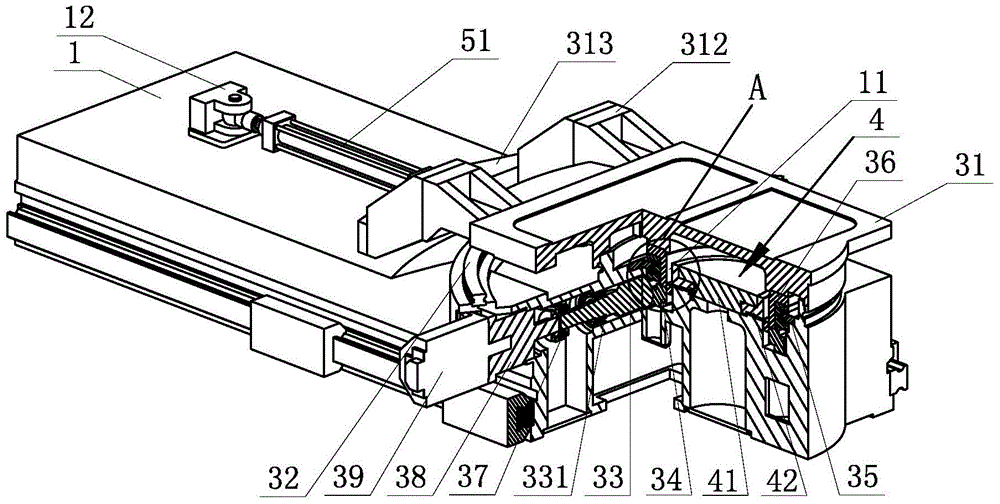

[0029] As shown in the figure, the AB pendulum type powerful five-axis linkage milling head includes a ram 1, an A-axis assembly, a B-axis assembly and a spindle housing 2. The spindle 21 is installed at the bottom of the spindle housing 2, and the A-axis assembly includes an A-axis. Slewing mechanism 3, A-axis clamping mechanism 4 and A-axis balance assembly 5 for balancing the roll force when A-axis swings, B-axis assembly includes B-axis slewing mechanism 6 and B-axis clamping mechanism 7, A-axis slewing mechanism 3 is used to drive the spindle housing 2 of the B-axis assembly to swing left and right, the A-axis clamping mechanism 4 is used to realize the clamping action of the A-axis, the B-axis rotary mechanism 6 is used to drive the spindle housing 2 to swing back and forth, and the B-axis clamping mechanism 7 It is used to realize the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com