Ship floating maintenance platform

A technology for repairing platforms and ships, which is applied in the field of floating platforms and special platforms, to achieve the effects of easy operation, reduced maintenance costs, and reduced lifting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

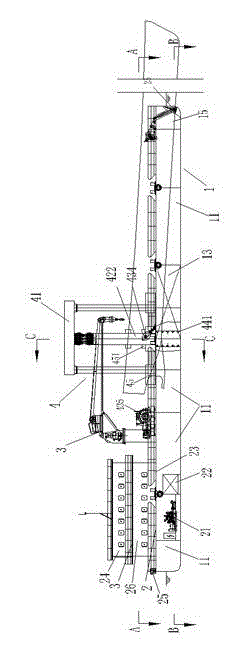

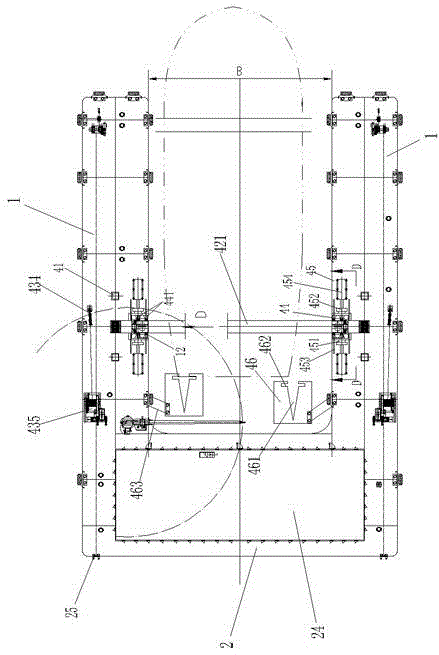

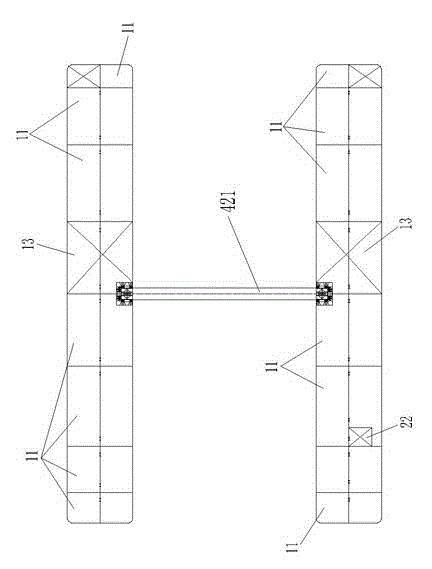

[0024] Such as Figure 1 to Figure 5 As shown, the present invention is a welded box structure surrounded by three sides and floating on the water surface in a C shape, including longitudinal floating bodies 1 on both sides and horizontal floating bodies 2 that are vertically fixedly connected to the longitudinal floating body 1 at both ends, the vertical floating body 1 and the horizontal floating body. The lower part of the buoyant body 2 is provided with multiple groups of empty chambers 11, which provide sufficient buoyancy for the present invention. Diesel generator set compartment 21 and fuel tank 22 are adjacently arranged in the bottom of transverse buoyancy body 2, which can save fuel delivery pipelines and also reduce the center of gravity of the present invention. The main deck 23 of the transverse buoyant body 2 of the present embodiment is provided with 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com