Hydrothermal purification method of lithium tetraborate

A lithium tetraborate and purification method technology, applied in the directions of tetrafluoroboric acid, borates, boron oxide compounds, etc., can solve the problems of unsatisfactory purification effect, complicated process and high cost, and achieve large-scale, simple process, high cost, etc. Install simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

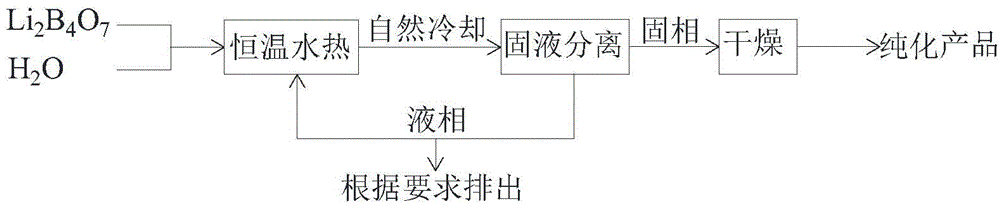

Method used

Image

Examples

Embodiment 1

[0039] Mix 2.5 g of commercial anhydrous lithium tetraborate solid and 47.5 g of deionized lithium tetraborate, add it to a hydrothermal reaction kettle, conduct a hydrothermal reaction at 100°C for 2 hours, take it out and cool it down to room temperature naturally. The solid-liquid was separated, and dried at 100° C. to obtain 1.3 g of purified lithium tetraborate trihydrate, with a yield of 48%. The obtained purified lithium tetraborate was detected, and the results are shown in Table 2:

[0040] Table 2 Chemical composition and impurity content in the purified lithium tetraborate of Example 1

[0041] Test items

Embodiment 2

[0043] Mix 7.5 g of commercial anhydrous lithium tetraborate solids with 42.5 g of deionized lithium tetraborate, add it to a hydrothermal reaction kettle, conduct a hydrothermal reaction at 120°C for 5 hours, take it out and cool it down to room temperature naturally. The solid-liquid was separated, and dried at 150°C to obtain 8.2 g of purified lithium tetraborate trihydrate, with a yield of 82%. The obtained purified lithium tetraborate was detected, and the results are shown in Table 3:

[0044] Table 3 Chemical composition and impurity content in the purified lithium tetraborate of Example 2

[0045] Test items

Embodiment 3

[0047] Mix 15 g of commercial anhydrous lithium tetraborate solid with 35 g of deionized lithium tetraborate, add it to a hydrothermal reaction kettle, conduct a hydrothermal reaction at 140°C for 10 hours, take it out and cool it down to room temperature naturally. The solid-liquid was separated, and dried at 180°C to obtain 18.1 g of purified lithium tetraborate trihydrate, with a yield of 92%. The obtained purified lithium tetraborate was detected, and the results are shown in Table 4:

[0048] Table 4 Example 3 Chemical composition and impurity content in the purified lithium tetraborate

[0049] Test items

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com