In-situ leaching uranium mine wastewater evaporating device and method

A mine wastewater and evaporation device technology, which is applied in mining wastewater treatment, energy wastewater treatment, general water supply conservation, etc., can solve the problems of high land acquisition and environmental protection requirements, small evaporation, and large impact of natural conditions, etc., to improve the evaporation of wastewater The effect of volume, reduced floor area, good economy and rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

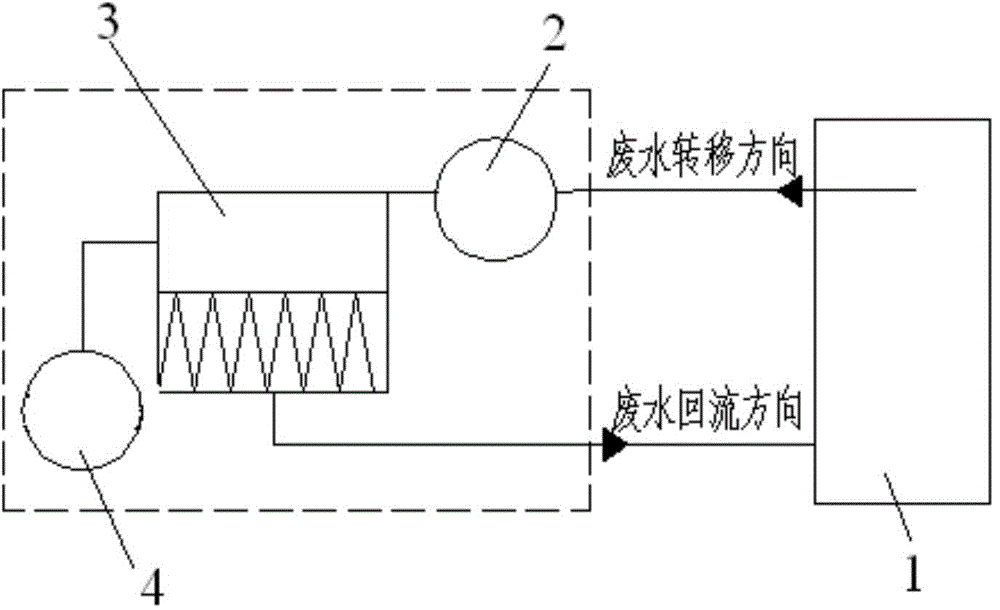

[0027] Such as figure 1 As shown, an in-situ leaching uranium mine wastewater evaporation method according to the present invention includes the following steps:

[0028] (a) The in-situ leaching uranium mine wastewater in the evaporation pond 1 is lifted into the evaporation device 3 using a submersible pump, the outdoor temperature is 20°C, and the waste water temperature is controlled to 16°C;

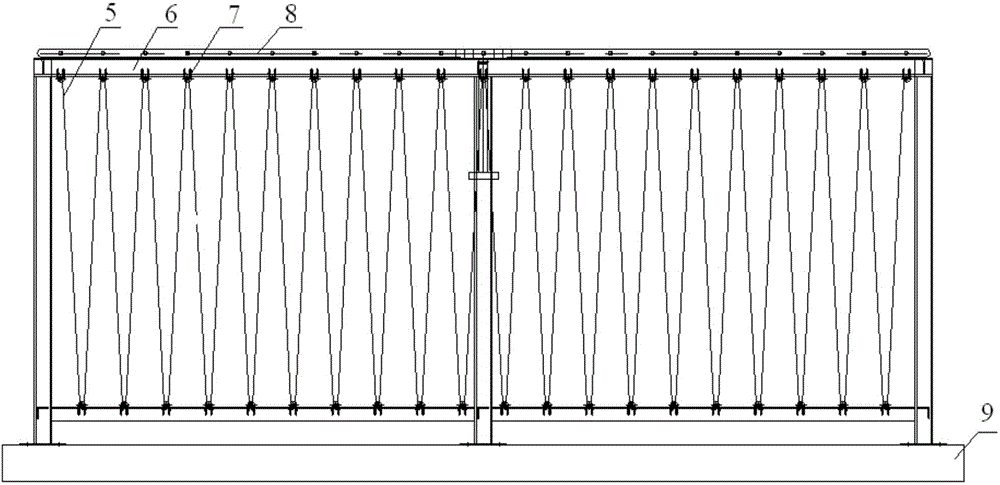

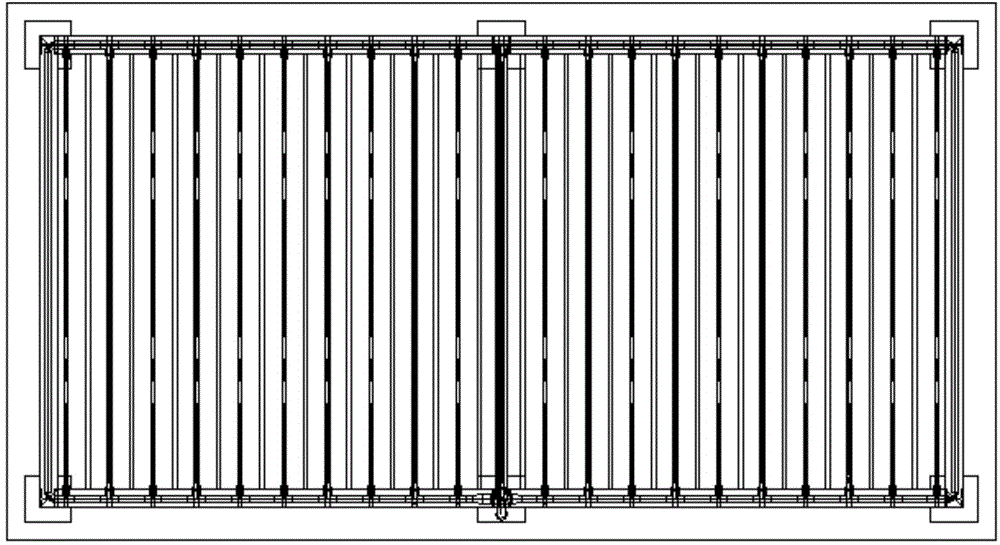

[0029] (b) In the evaporator 3, the wastewater enters the liquid distribution pipe 8, and is evenly sprayed on the base material 5 through the liquid distribution hole on the liquid distribution pipe 8 to evaporate; the wastewater inlet time is 5 minutes, and the inlet volume is 290g / m 2 ; Control air humidity 46%RH, wind speed 1.5m / s; the overall water retention capacity of the base material is about 31kg; the base material is polypropylene woven cloth or carbon fiber woven cloth;

[0030] (c) Waiting for 25 minutes, all the wastewater adsorbed on the base material 5 evaporates completel...

Embodiment 2

[0038] Such as figure 1 As shown, an in-situ leaching uranium mine wastewater evaporation method according to the present invention includes the following steps:

[0039] (a) The in-situ leaching uranium mine wastewater in the evaporation pond 1 is lifted to the evaporation device 3 using a submersible pump, the outdoor temperature is 25°C, and the waste water temperature is controlled to 10°C;

[0040] (b) In the evaporator 3, the wastewater enters the liquid distribution pipe 8, and is evenly sprayed on the base material 5 through the liquid distribution holes on the liquid distribution pipe 8 to evaporate; the water inlet time is 5min, and the liquid inlet amount is 289g / m 2 ; Control air humidity 39%RH, wind speed 2.1m / s; the overall water retention capacity of the base material is about 30kg; the base material is polypropylene woven cloth or carbon fiber woven cloth;

[0041] (c) Waiting for 25 minutes, all the wastewater adsorbed on the base material 5 evaporates completely, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com