A kind of high dry point heavy distillate oil hydrocracking method

A heavy distillate oil, hydrocracking technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of increasing the difficulty of hydrogenation, slowing down the diffusion speed, and reducing the reaction speed, etc. Strong effect, lower inhibitory effect, good activity stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

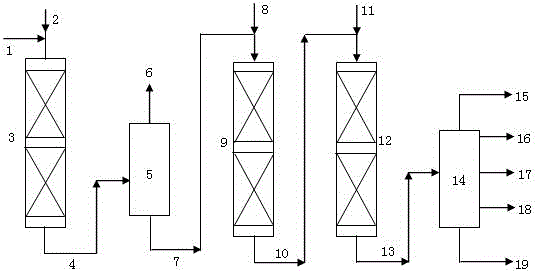

[0045] use figure 1 Process flow shown. Hydrofining catalyst A is used in both the first and second stages, and FC-50 catalyst is used in the third stage; the refined nitrogen content in the second stage is controlled to be 15~25μg / g, and the cracking stage adopts a single pass process, and the cracking stage is controlled >370°C single-pass conversion is ~70wt%.

Embodiment 2

[0047] use figure 1 Process flow shown. Hydrofining catalyst B is used in both the first and second stages, and FC-50 catalyst is used in the third stage. The refined nitrogen content in the second stage is controlled to be 15~25μg / g, the cracking section adopts a single-pass process, and the single-pass conversion rate of the cracking section>370°C is controlled to ~70wt%.

Embodiment 3

[0049] use figure 1 In the process flow shown, the first stage uses hydrofinishing catalyst A, the second stage uses hydrotreating catalyst B, and the third stage uses FC-50 catalyst. The refined nitrogen content in the second stage is controlled to be 15~25μg / g, the cracking section adopts a single-pass process, and the single-pass conversion rate of the cracking section>370°C is controlled to ~70wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com