Textile shaping and drying all-in-one machine

A technology of setting drying and all-in-one machine, applied in dryers, textiles, papermaking, drying and other directions, can solve problems such as low efficiency and cumbersome processes, and achieve the effects of improving work efficiency, reducing pollution and reducing defective rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the invention is not limited by the embodiments.

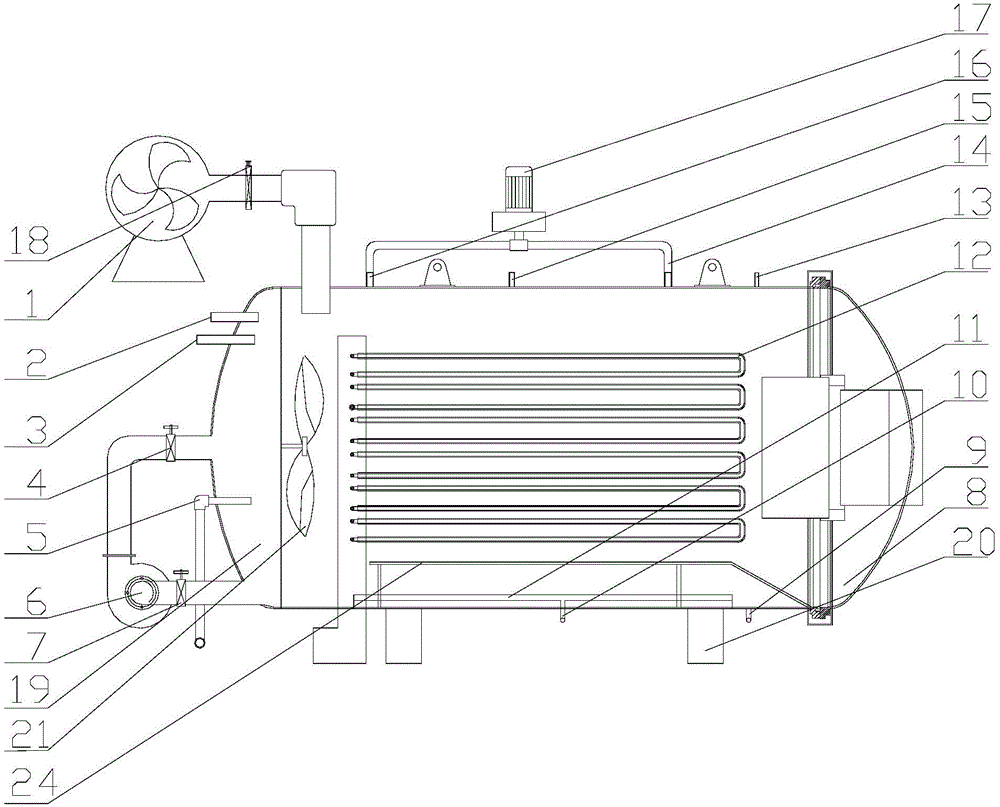

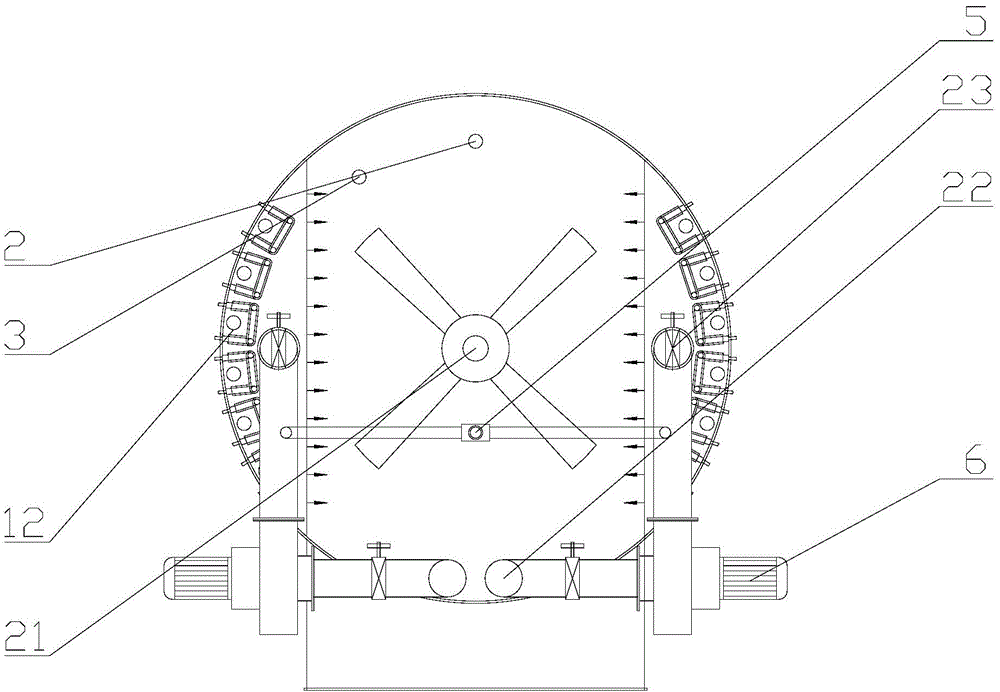

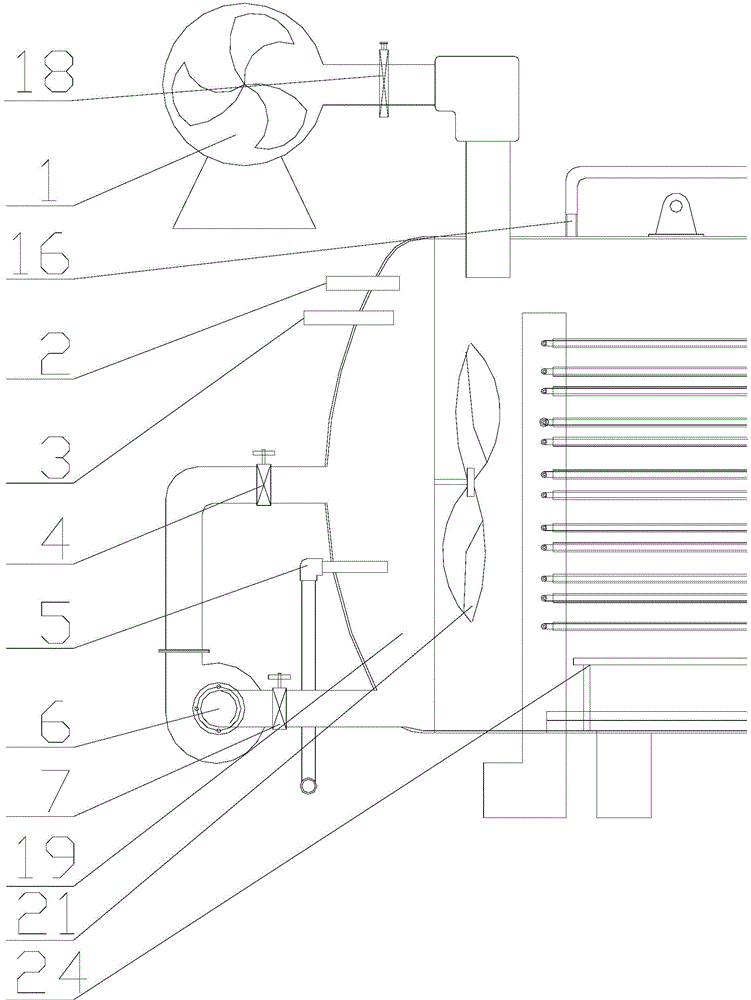

[0019] See figure 1 , figure 2 , image 3 , Figure 4 As shown, an all-in-one textile drying machine is mainly composed of a base 20, a body 19, and a sealed door 8, and also includes an electric heating tube 12, a vacuum pump 1, a dehumidification fan 17, a circulation fan 6, a magnetic automatic fan 21, and a high-pressure sprayer. Sprinkler pipe 5, safety valve 15, exhaust valve 9, steam plate 11 and steam interface 10; the body 19 is made of steel plate and is in the shape of a barrel, and the front side of the body 19 is provided with a sealed door that fits with the body 19 8. The airtight door 8 is connected with the body 19 by hinges; the inside of the body 19 is provided with electric heating tubes 12, and the electric heating tubes 12 are arranged in two rows, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com