Steel-concrete multi-chamber beam-slab floor and its processing technology

A technology of floor and beam slab, applied to bridges, bridge parts, bridge materials, etc., can solve the problems of large floor of reinforced concrete structure, low bending strength of all-steel single-layer thick steel plate, inconvenient construction and transportation, etc. Achieve the effects of being conducive to ecological construction, enhancing bearing capacity, and facilitating deflection control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

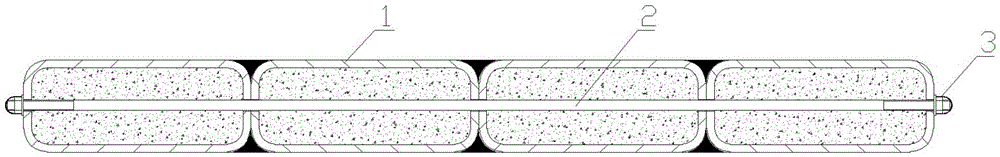

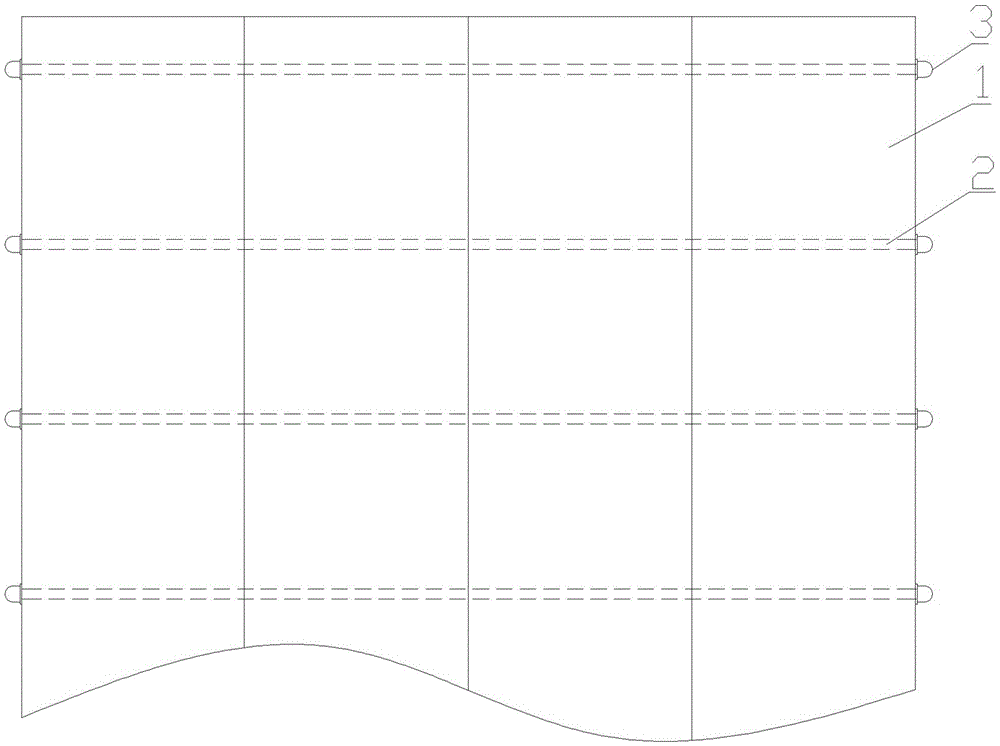

[0017] see figure 1 and figure 2 , the base plate in this embodiment is composed of two or more rectangular tubes 1 arranged side by side, fastened by means of connectors penetrating transversely, and the connecting surfaces between adjacent rectangular tubes are welded to form an integrated structure. The cavity of each rectangular tube Injection concrete in the body. Specifically, the rectangular tubes 1 arranged in parallel are evenly distributed with corresponding threaded holes or through holes along their longitudinal direction, and are fastened by means of screw rods 2 connected in series. The nuts at both ends of the screw rods are also provided with protective decorative caps 3 . The through holes can be configured as slot-shaped holes, so as to reduce the precision requirements for connecting the rectangular tubes and improve the processing efficiency of the bottom plate.

[0018] Two rows of threaded holes or through holes are arranged on the same side of the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com