Oil-water separator

An oil-water separation device and a technology for residual oil, which are used in general water supply conservation, water conservancy projects, and open-air water surface cleaning, etc., and can solve problems such as the inability to quickly recover small river channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

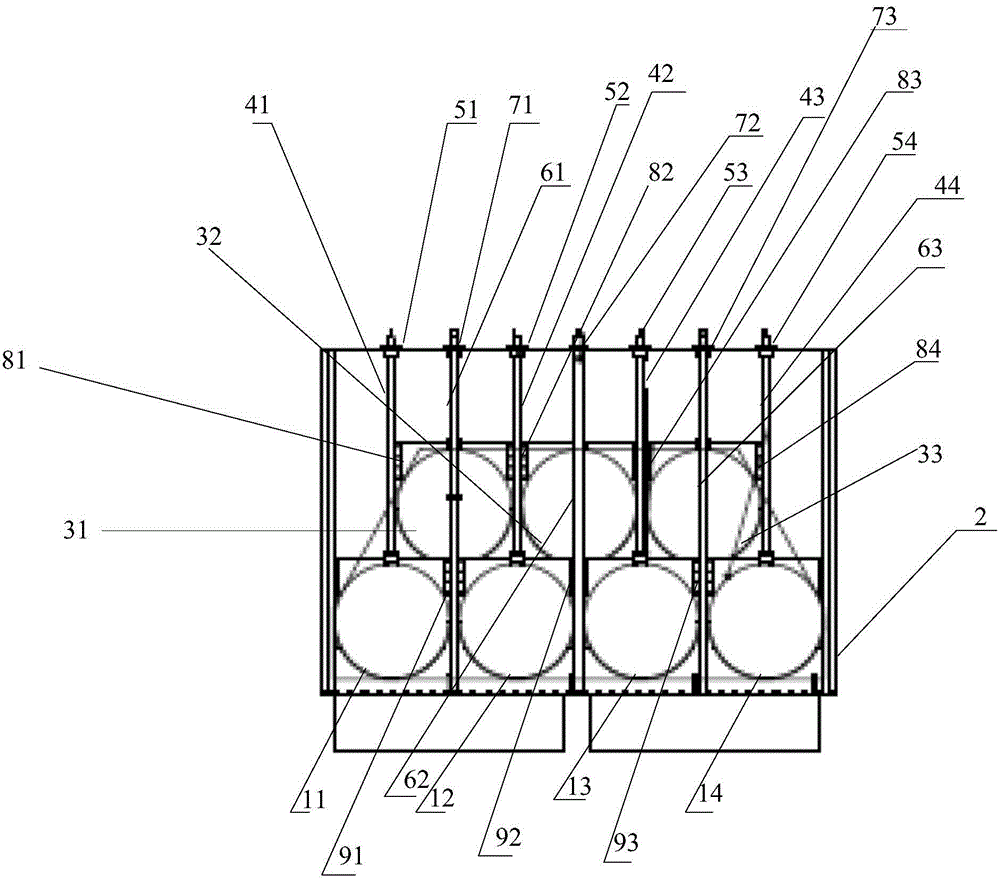

[0029] This embodiment provides an oil-water separation device, such as figure 1 As shown, the device includes: a first group of rams 1, a frame 2, a second group of rams 3, a first group of lead screws 4, and a second group of lead screws 5; wherein,

[0030] One end of the first group of gates 1 is arranged on the upper end of one side of the frame 2, and one side of the first group of gates 1 is attached to the first group of sealing grooves; the first group of gates 1 at least includes: The first gate plate 11, the second gate plate 12, the third gate plate 13 and the fourth gate plate 14; the first set of sealing grooves at least include: the first sealing groove, the second sealing groove, the third sealing groove and the first sealing groove Four sealing grooves.

[0031] The second group of rams 3 is arranged above the first group of rams 1, and one side of the second group of rams 3 is attached to the second group of sealing grooves; the second group of rams at least...

Embodiment 2

[0053] In practical application, when using the oil-water separation device provided by the present invention to carry out residual oil recovery in small rivers, the main steps are as follows:

[0054] 1) Site selection.

[0055] The water volume of small rivers has the characteristics of obvious seasonal changes, and the width of the river bed is different. Therefore, when choosing the location of the oil-water separation device, three factors should be considered: the width of the river bed, the height of the water level, and the velocity of the water flow. For example, for seasonal rivers, during the flood season, the water level is high and the flow velocity is fast. When selecting a location, avoid areas with high water level and high flow velocity, and choose locations with low flow velocity and low water level to facilitate device assembly and later oil-water separation. operate. When the river is in the dry season, you should choose a section with a relatively flat ri...

Embodiment 3

[0063] Utilize the oil-water separation device provided by the present invention, in the emergency drill of leaking oil spilled into the river held in a small river basin, 5 oil product interception points were set in combination with the channel width of the river and upstream tributaries and the river water flow conditions; At 3.9 kilometers from the point, the water velocity is about 0.2m / s, and the flow rate is 1m 3 / s, the width of the river bed is about 6 meters, combined with the situation of the river on site, the oil-water separation device and the earth dam shall be combined to implement the interception and recovery of oil products.

[0064] When an emergency occurs when oil spills into the ditch, the emergency repair personnel choose the river where the river bed is narrow and the river water flow is small, and the construction vehicles can easily enter the river, and place the oil-water separation device on the bank to prepare for equipment installation. The excav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com