Intelligent closestool testing production line

A smart toilet and production line technology, applied in the testing of machines/structural components, measuring devices, flushing toilets, etc., can solve the problems of wasting manpower and working time, reducing production efficiency, and difficulty in achieving high efficiency, so as to improve detection efficiency and Effects of monitoring, reducing product damage, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

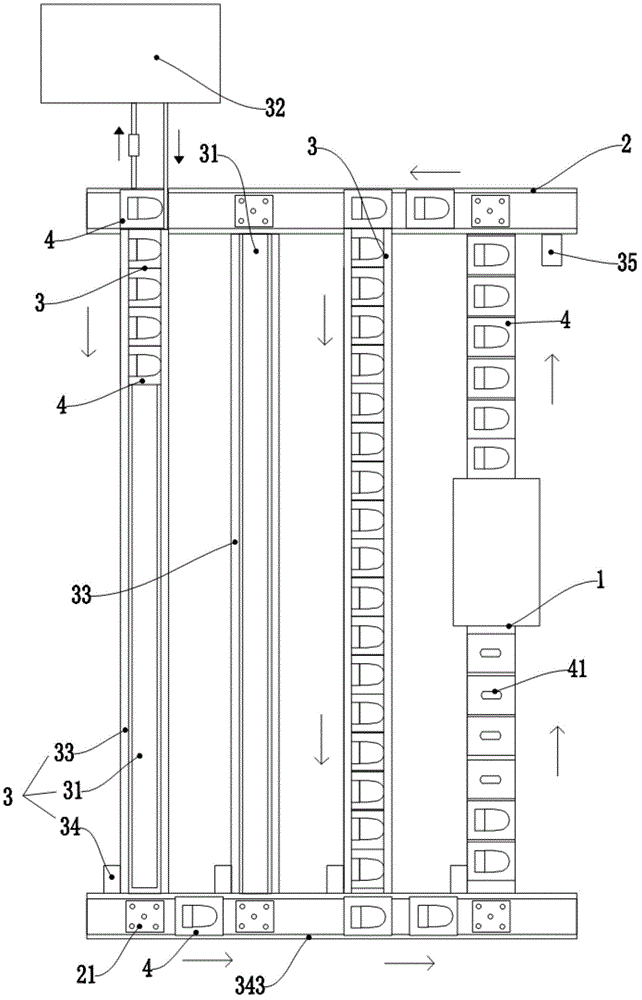

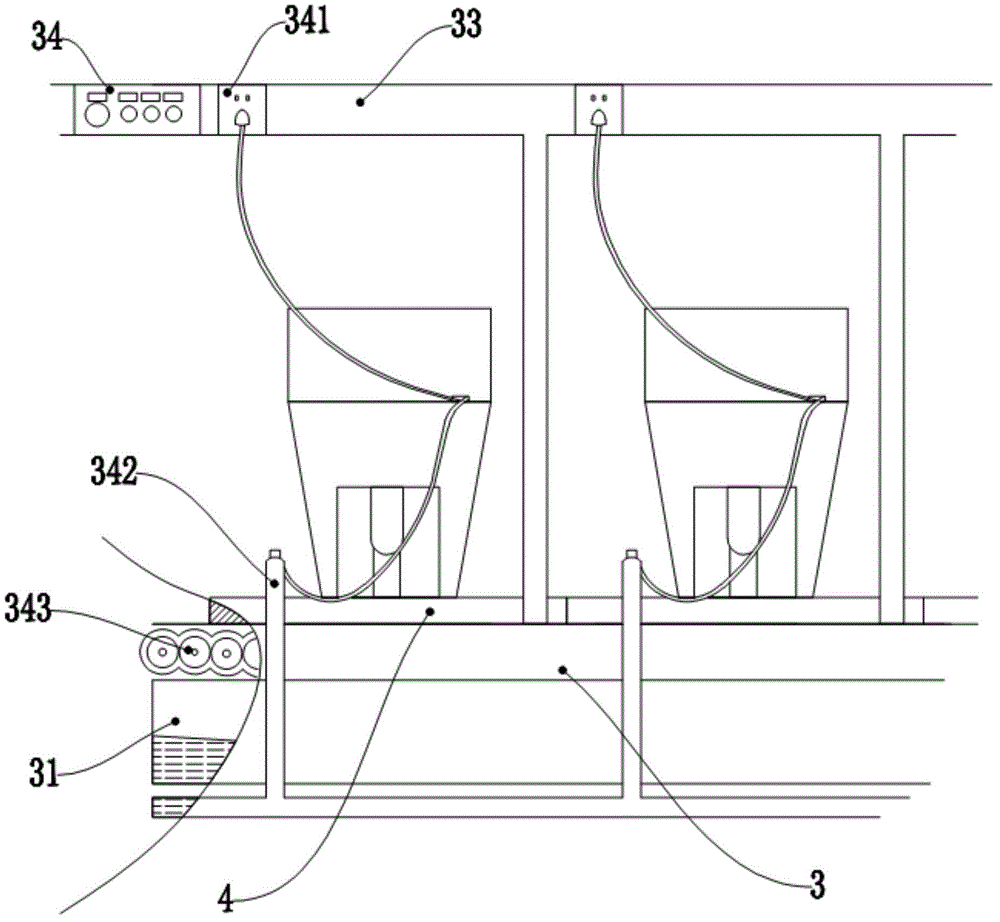

[0022] The intelligent toilet test production line includes an online and offline module for moving and taking the intelligent toilet 1, a transversal transition module 2 for rotating the intelligent toilet, and a test module 3 for detecting the aging of the intelligent toilet;

[0023] The first and last ends of the online and offline module 1 and the test module 3 correspond to each other, and are connected to each other by the traverse transition module 2 to form a closed loop;

[0024] After the smart toilet to be tested is placed on the running line of the online and offline module 1, it is transmitted by the online and offline module 1, and enters the testing module 3 through the traverse transition module 2 for testing. After the test is completed Return to the operating line of the online and offline module 1 via the other tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com