A calibration method for a production logging well temperature instrument

A well temperature and instrument technology, which is applied in the field of new calibration of production logging well temperature instruments, can solve the problems of small range of adjustable resistance resistance, low calibration accuracy, and large influence of temperature drift, so as to reduce well temperature The effect of measuring error, improving adjustment accuracy and saving adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

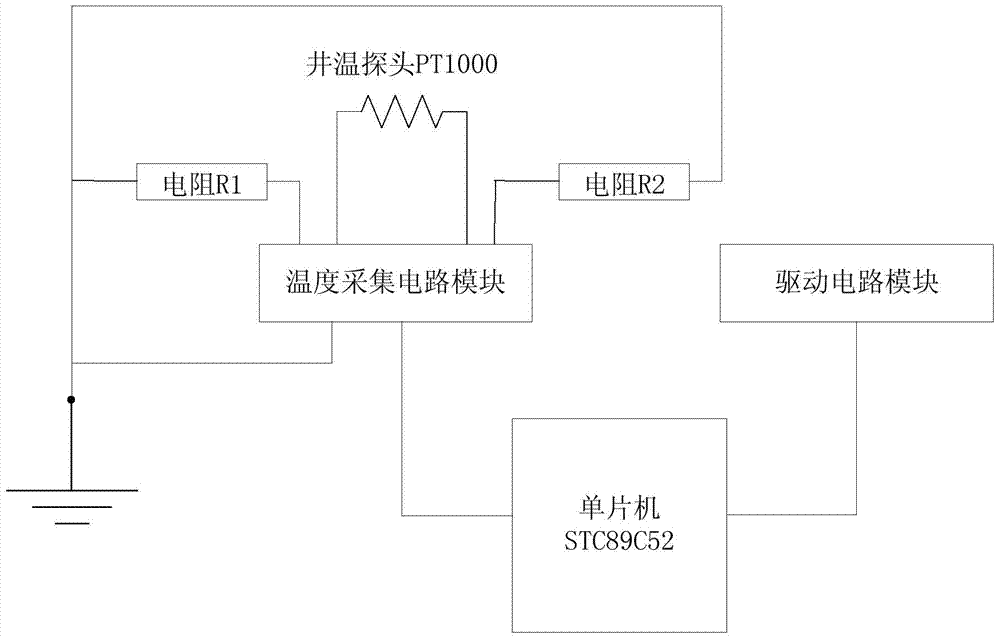

[0037] refer to figure 1 The block diagram of the instrument circuit, including well temperature probe PT1000, fixed resistors R1, R2 temperature acquisition circuit module, single-chip microcomputer STC89C52, and drive circuit module. in:

[0038] The temperature acquisition circuit module is used to collect, amplify, and shape the voltage signal of the well temperature probe, and transmit it to the single-chip microcomputer;

[0039] The well temperature probe can measure the change of external temperature by detecting the change of temperature;

[0040] The driving circuit module is used to transmit the output signal of the single-chip microcomputer to the ground operating system;

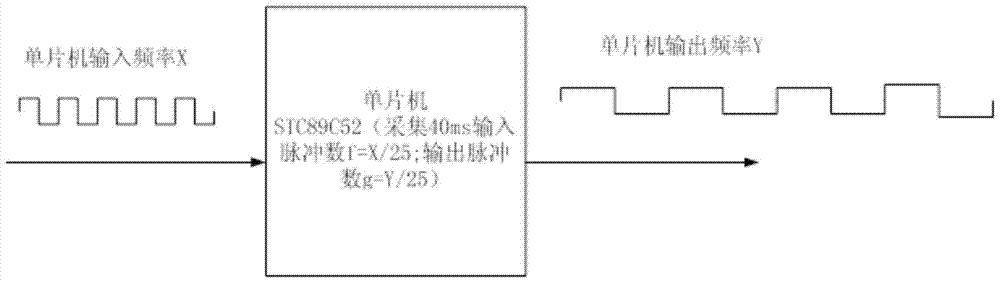

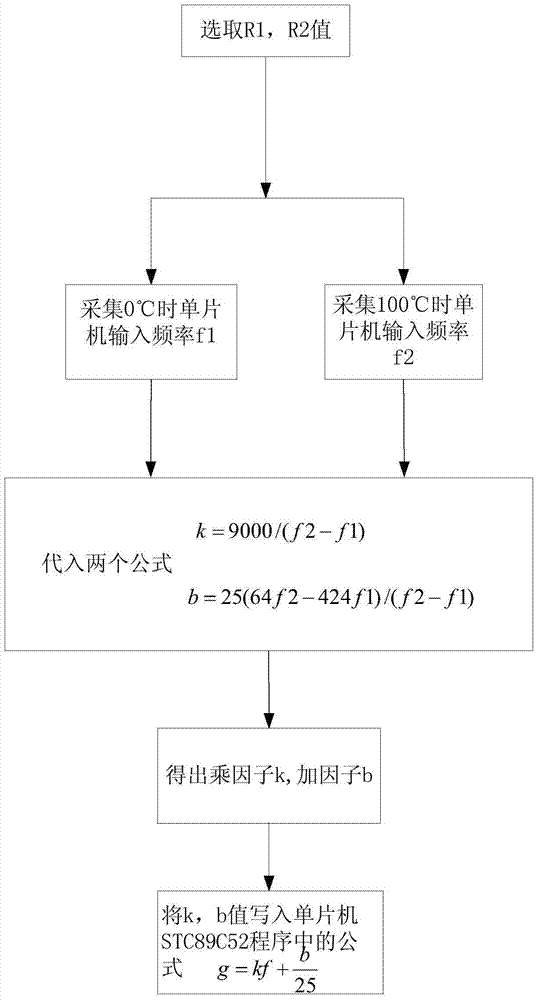

[0041] The single-chip microcomputer, through the relational expression g=kf+b / 25 of its input signal pulse number and output signal pulse number, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com