Coal-mass gas extraction method and device

A technology for gas extraction and coal body, which is applied in the field of coal body gas extraction device and coal body gas extraction, can solve the problems of not being able to guarantee the safe production of coal mines in a short time, not being able to use effectively, and wasting good resources, etc. To achieve the effect of shortening the extraction time, reducing the impact and making full use of it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

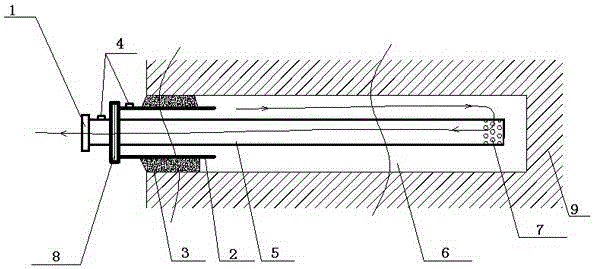

[0020] Such as figure 1 As shown, a coal gas drainage method is used for coal that is not easily broken. A drainage pipe 5 is laid from the orifice of the drainage borehole 6 to the bottom of the hole. The front end of the drainage pipe 5 is connected with the hole sealing device, and the end is set The secondary drainage hole 7 is drained by the negative pressure source pipe 1 of the mine drainage system connected to the plugging device, so that the gas in the drainage borehole flows to the bottom of the drainage borehole 6 from the secondary drainage hole 7 Into the drainage pipe 5.

[0021] A coal gas drainage device used in the above method includes a negative pressure source pipe 1 connected with a mine drainage system and a plugging pipe 2 installed at the orifice of the drainage borehole 6. The negative pressure source pipe 1 is movably connected to the plugging pipe 2. A plugging material 3 is provided between the two sides of the plugging pipe 2 and the drainage borehole...

Embodiment 2

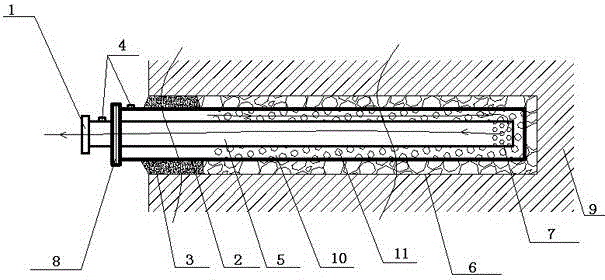

[0025] Such as figure 2 As shown, a coal gas drainage method is used for fragile coal. A drainage pipe 5 is laid from the orifice of the drainage borehole 6 to the bottom of the hole. The front end of the drainage pipe 5 is connected with the hole sealing device, and the end is set The auxiliary drainage hole 7 is connected to the supporting pipe 10 at the end of the plugging device, and the drainage pipe 5 is located in the cavity enclosed by the plugging device and the supporting pipe 10 to prevent coal from squeezing the drainage pipe 5 and blocking the drainage The mining borehole 6, through the drainage of the negative pressure source pipe 1 of the mine drainage system connected with the plugging device, causes the gas in the drainage borehole 6 to flow to the bottom of the drainage borehole 6, from the secondary drainage hole 7 Into the drainage pipe.

[0026] A coal gas drainage device used in the above method includes a negative pressure source pipe 1 connected with a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com