Columnar hydraulic tappet

A hydraulic tappet and columnar technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of low processing efficiency, multi-process, time-consuming and labor-intensive, etc., to avoid hole processing waste, simple plunger structure, Good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

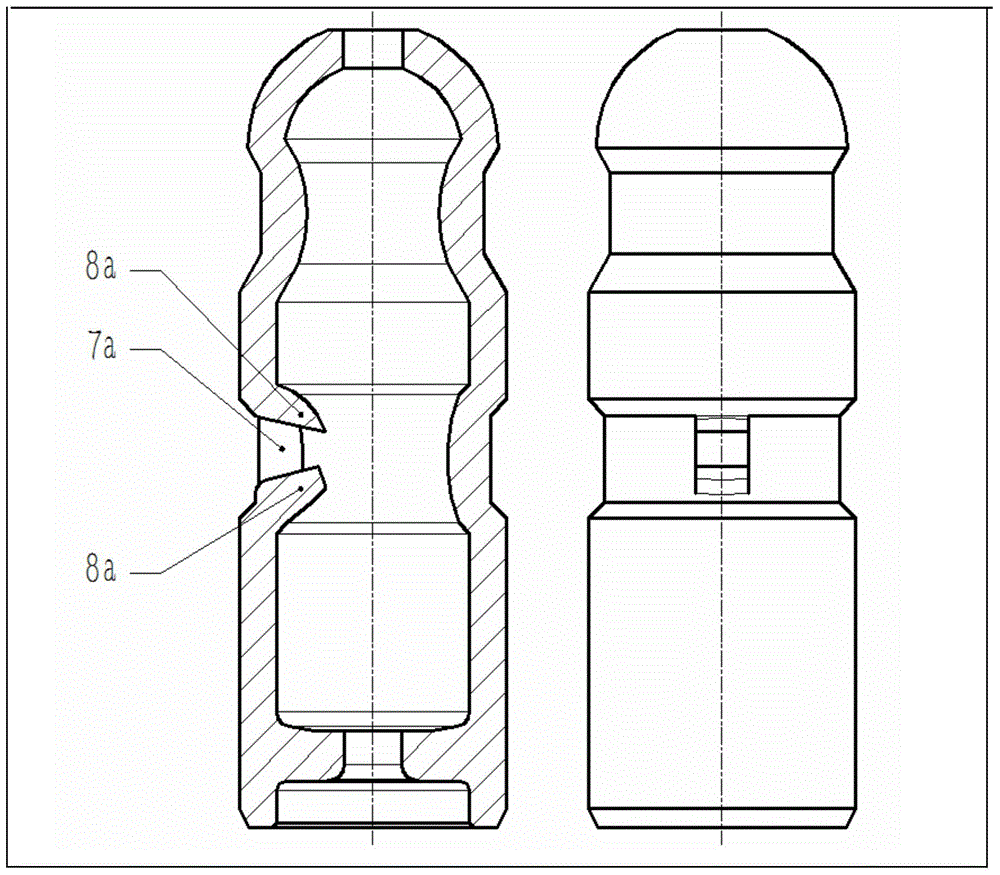

Embodiment 1

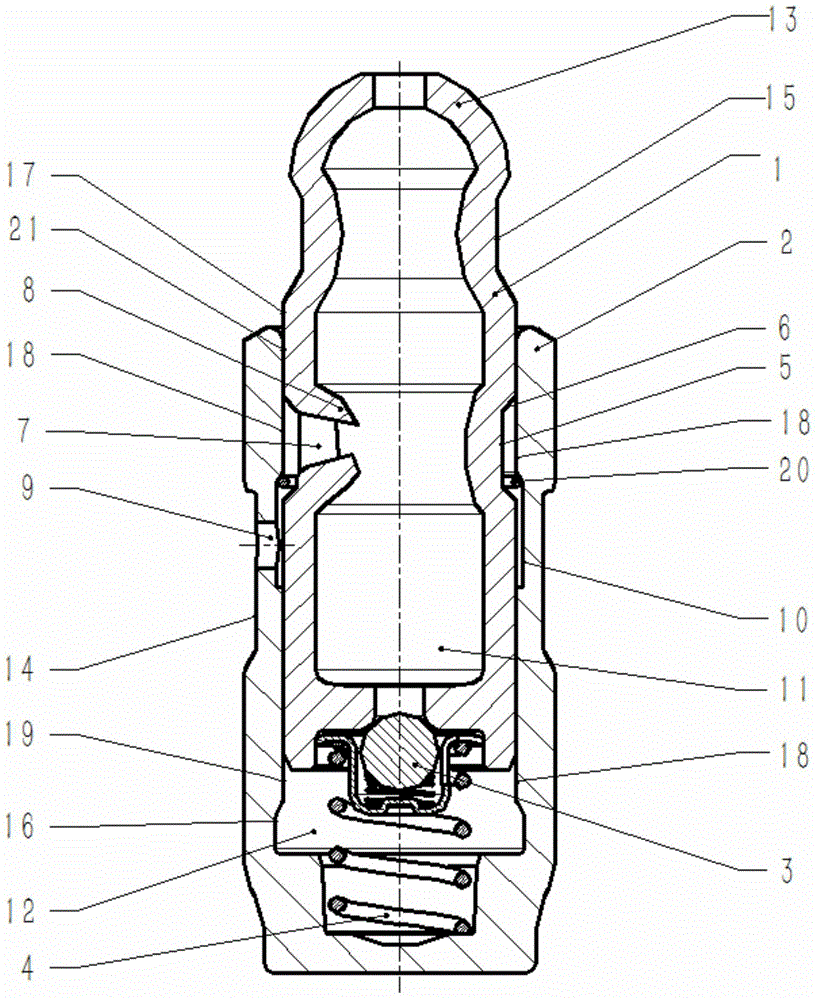

[0053] Such as figure 1As shown, the columnar hydraulic tappet used in the engine valve train has a pot-shaped housing (2), and an axially slidable plunger is arranged in the inner cavity of the housing (2) (1). There is a high-pressure chamber (12) between the lower end surface of the plunger (1) and the housing (2), and the high-pressure chamber (12) can be closed by a one-way valve (3) located at the lower end of the plunger (1). There is a return spring (4) connecting the plunger (1) and the housing (2) in the high-pressure chamber (12). On the outer diameter of the housing (2) there is an outer ring groove (14) for the circulation of the hydraulic medium, and on the radial inner side of the housing (2) there is an inner ring groove (10) for the circulation of the hydraulic medium. One or more oil holes (9) for the circulation of hydraulic medium are provided between the inner ring groove (10) of the housing and the outer ring groove (14) of the housing. The inner wall o...

Embodiment 2

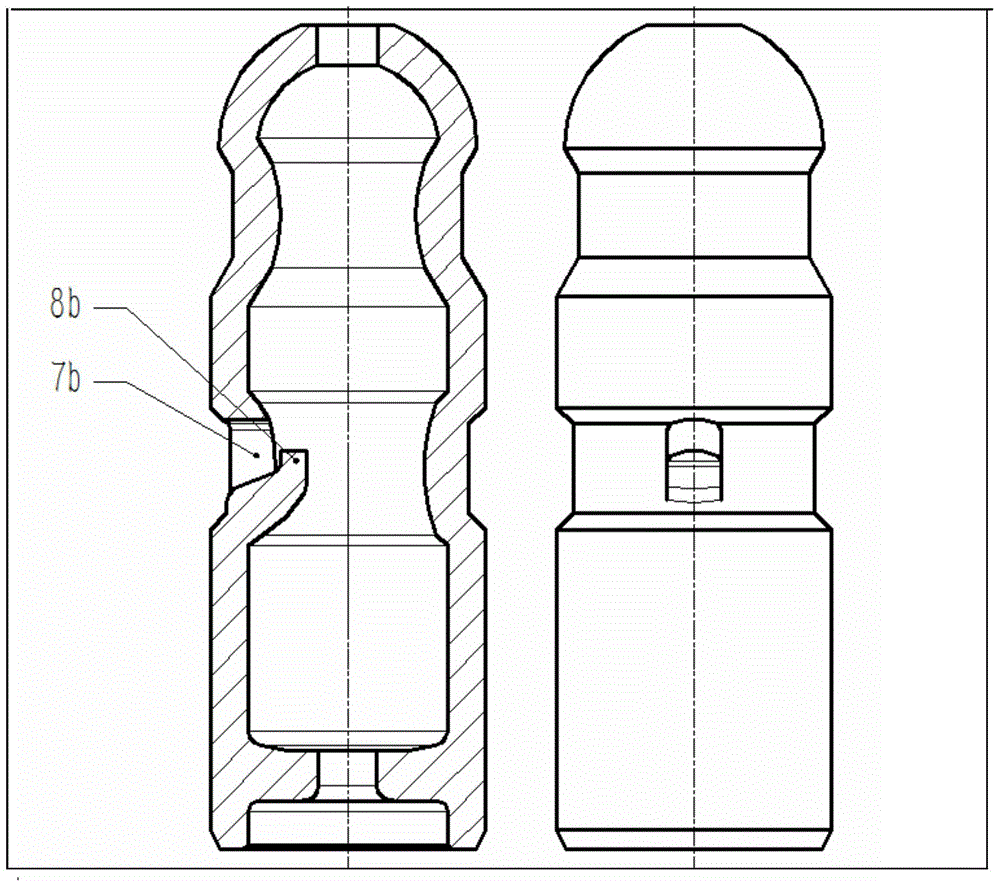

[0059] Such as image 3 As shown, the difference from Embodiment 1 is that the structure of the plunger oil inlet hole (7b) is a single-sided window structure, and the window opening direction is upward.

Embodiment 3

[0061] Such as Figure 4 As shown, the difference from Embodiment 1 is that the structure of the plunger oil inlet hole (7c) is a single-sided window structure, and the window opening direction is downward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com