Calibration method of coupling position relationship between micro lens array and detector

A technology of microlens array and calibration method, applied in the field of instrument parameter calibration, can solve the problems of low precision, calibration, poor result stability, etc., and achieve the effect of simple application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

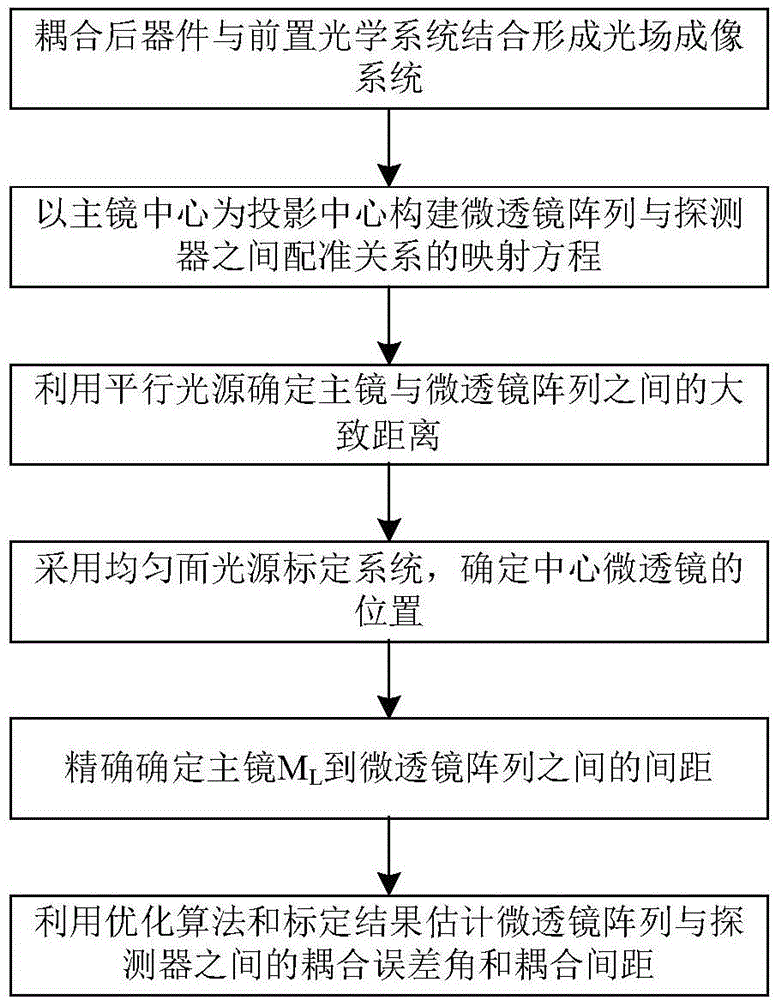

[0019] The present invention is a method for calibrating the coupling position relationship parameters for the microlens array and the detector coupling device, the process is as follows figure 1 shown, including the following steps:

[0020] Step 1: Combining the microlens array and the detector coupled device with the pre-optical system to form a light field imaging system.

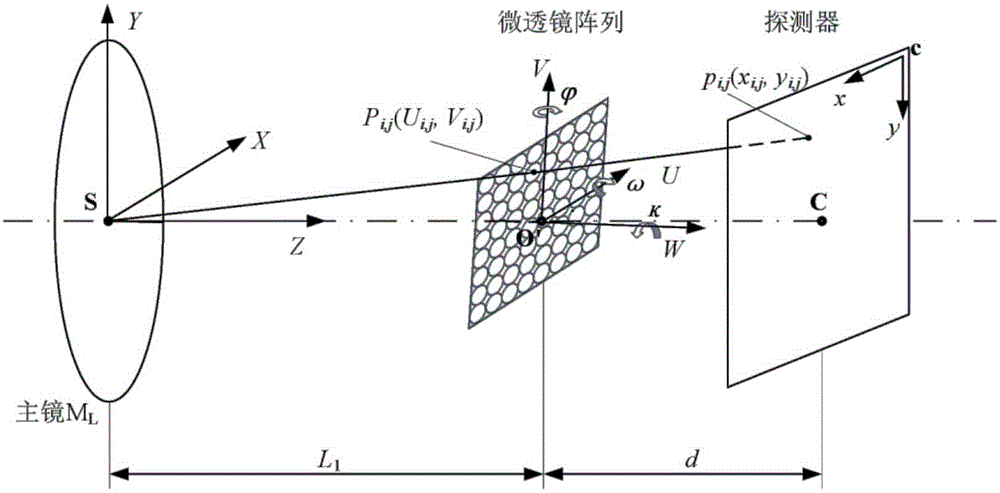

[0021] Coupling the microlens array and the detector, the ideal distance between the two is the focal length f of the microlens m , the actual distance is d, which is the parameter to be calibrated. There are inclination and oblique angles between the plane where the coupled microlens array is located and the plane where the detector is located, that is, the following coupling rotation error angle , ω, κ are also parameters to be calibrated. The coupled device is combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com