Manufacturing method of backside image sensor

An image sensor, back-illuminated technology, used in semiconductor/solid-state device manufacturing, radiation control devices, electrical components, etc., can solve the problems of poor optoelectronic characteristics and output quality, high manufacturing costs, and complex manufacturing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

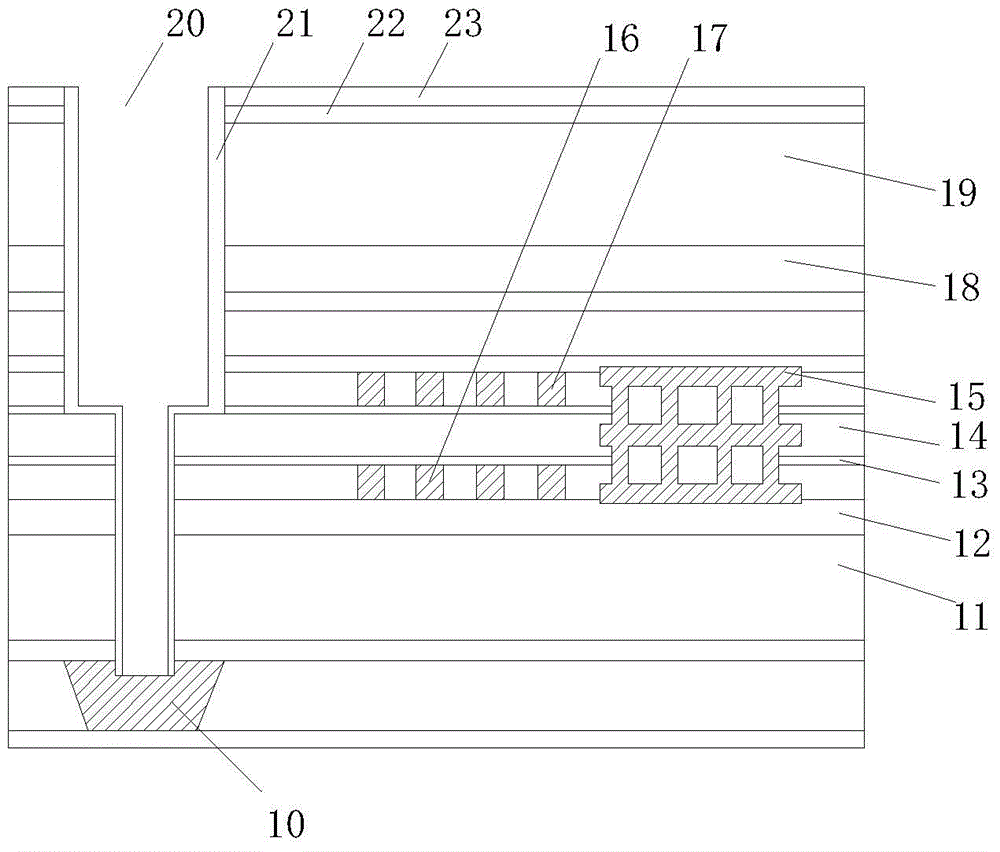

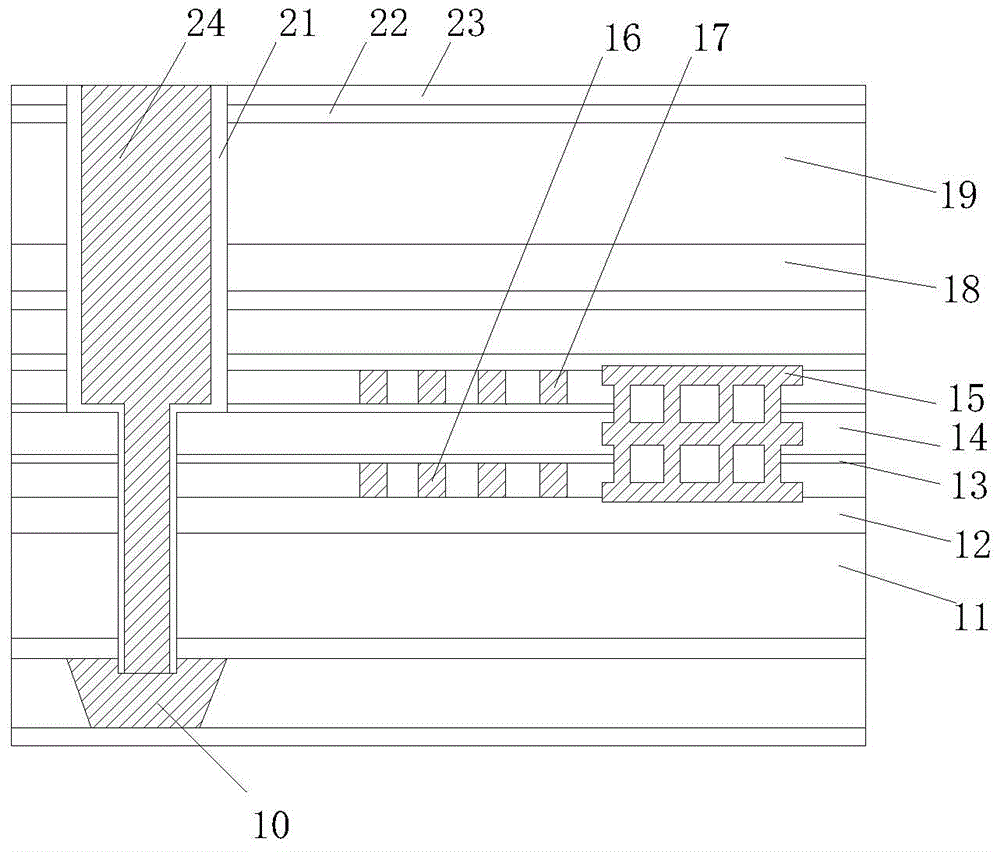

[0040] The core idea of the present invention is to integrate the metal leads of the back-illuminated image sensor with the Pad, and simultaneously prepare the metal isolation barrier to provide the basis for the subsequent color filter buried process, thereby improving the simplification of the image sensor manufacturing process , reduce the preparation cost and improve the output image quality.

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

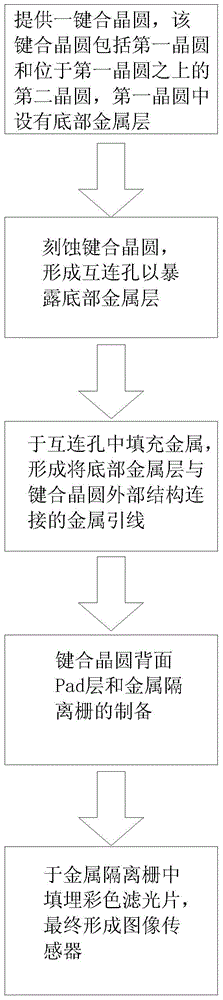

[0042] Such as figure 1 Shown is the flow chart of the preparation method of the back-illuminated image sensor in the embodiment of the present invention. First, provide a bonded wafer with a photosensitive area (that is, a metal isolation barrier and a buried color filter area) and a bottom metal layer; secondly, etch the bonded wafer to form an exposed bottom metal layer. Interconnect holes on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com