Anti-interference laser cultivating and harvesting integrated machine

A laser and laser light source technology, applied in harvesters, container cultivation, and optical devices, can solve problems such as lowering prices, inability to survive, and consuming nutrients, and achieve the effects of increasing production, ensuring seedling quality, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

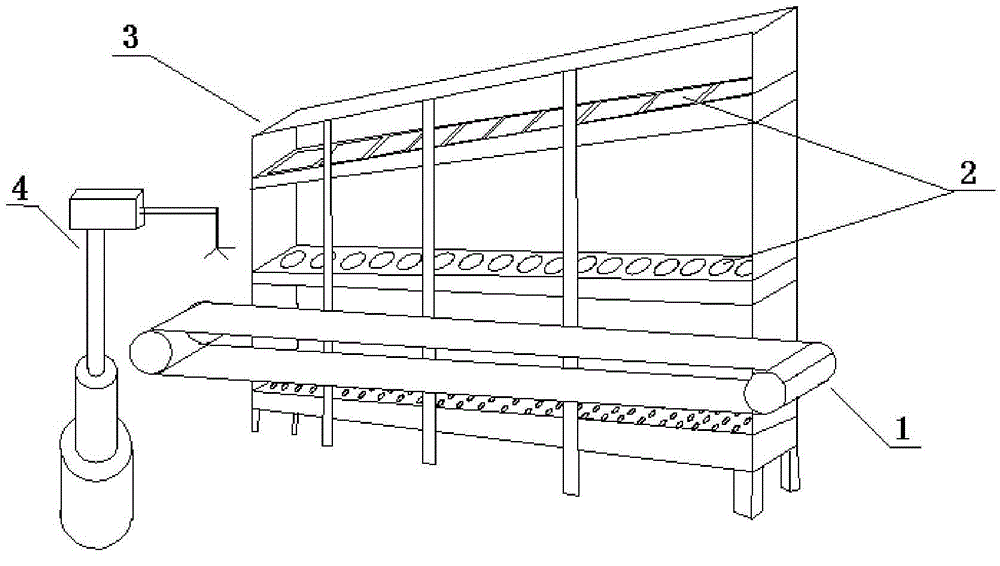

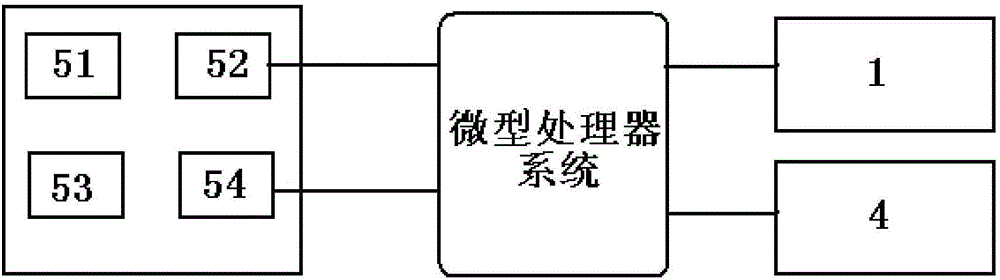

[0025] refer to figure 1 and figure 2 , an anti-jamming laser cultivation and harvesting integrated machine, comprising a seedling cultivation carrier 3, on which a cultivation container 2 for containing culture materials is placed. Seedling cultivation carrier 3 can be ground, also can be support. The cultivation container 2 can be a cultivation bottle, a cultivation box, a cultivation box and the like. The selection of the cultivation container 2 can be determined by the species of the cultivated seedlings and the selected cultivation method. The anti-interference laser cultivation and harvesting integrated machine also includes an optical scanning system. The optical scanning system includes a left light emitting light source 51 on the left side of the seedling cultivation carrier 3, a right photosensitive element 52 on the right side of the seedling cultivation carrier 3, and the left light emitting light source 51 and the right photosensitive element 52 form a facing ...

specific Embodiment 2

[0029] refer to figure 1 and figure 2 , an anti-interference laser cultivation and harvesting integrated machine, comprising a seedling cultivation carrier 3 on which a cultivation container 2 is placed. The anti-interference laser cultivation and harvesting integrated machine also includes an optical scanning system. The optical scanning system includes a left light emitting light source 51 on the left side of the seedling cultivation carrier 3, a right photosensitive element 52 on the right side of the seedling cultivation carrier 3, and the left light emitting light source 51 and the right photosensitive element 52 form a facing layout. The height of the right photosensitive element 52 and the left light emitting light source 51 is equal to the set seedling growth height. The optical scanning system also includes a front photosensitive element 54 positioned at the front of the seedling cultivation carrier 3, and a rear light source 53 positioned at the rear of the seedli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com