Tofu skin conveyor dryer

A dryer and bean curd skin technology, applied in the direction of progressive dryers, dryers, conveyors, etc., can solve the problems of low degree of drying and mechanization, restricting the quality and efficiency of enterprises and institutions, and the ineffectiveness of solar houses, etc., to achieve cleanliness Easy to control, compact structure, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

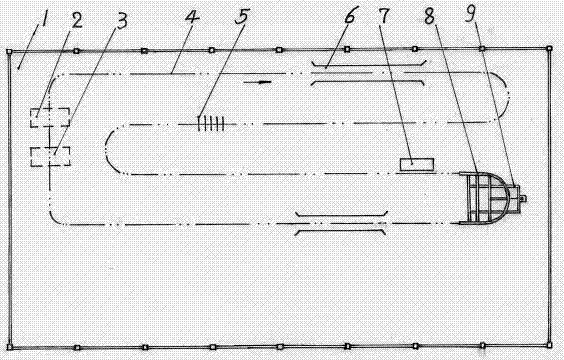

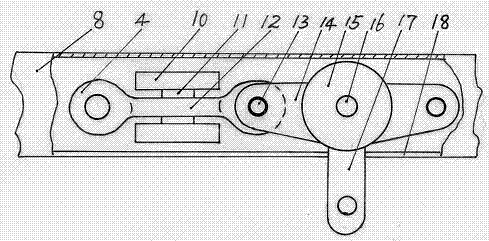

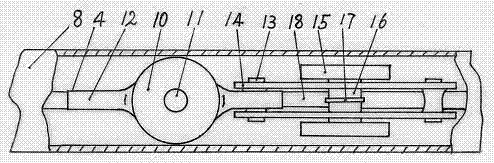

[0041] The following is an example of a conveyor dryer provided by the applicant's unit, and the present invention will be further illustrated with the drawings.

[0042] Such as Figure 1-10 As shown, the entire machine is arranged in the original rot production plant 1, which is located in the local industrial park, and is a standard plant leased to the applicant by the local government.

[0043] As described above, the trough rail 8 is installed and fixed on the ceiling or the beam by a connecting member such as the support frame 21, where the support frame is a fixed rod, and the upper end is fixed to the ceiling or the beam. The lower slot 18 of the trough rail faces downwards, and the trough rail is installed in multiple sections, and the places where there are turns and up and down slopes are deformed accordingly. The tensioning device 9 is set at the 180-degree turn of the grooved rail. The tensioning is to separate a section of the semi-circular arc from the straight part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com