Solid feed additive, preparation method thereof, and feed

A feed additive and solid technology, which is applied in the field of feed for dairy cows and solid feed additives for dairy cows, can solve the problems of easy moisture absorption and caking, poor use effect, etc., and achieve the effect of increasing milk production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

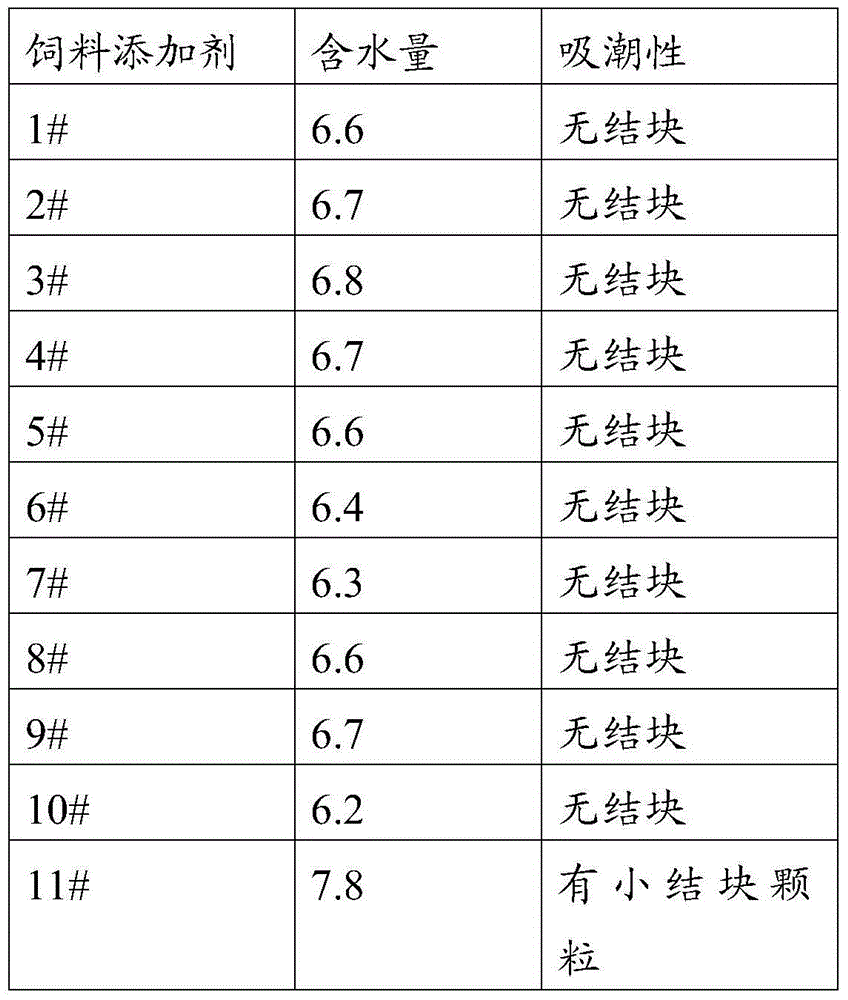

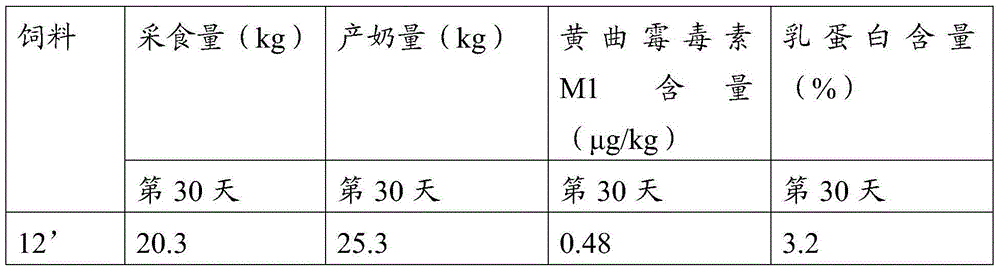

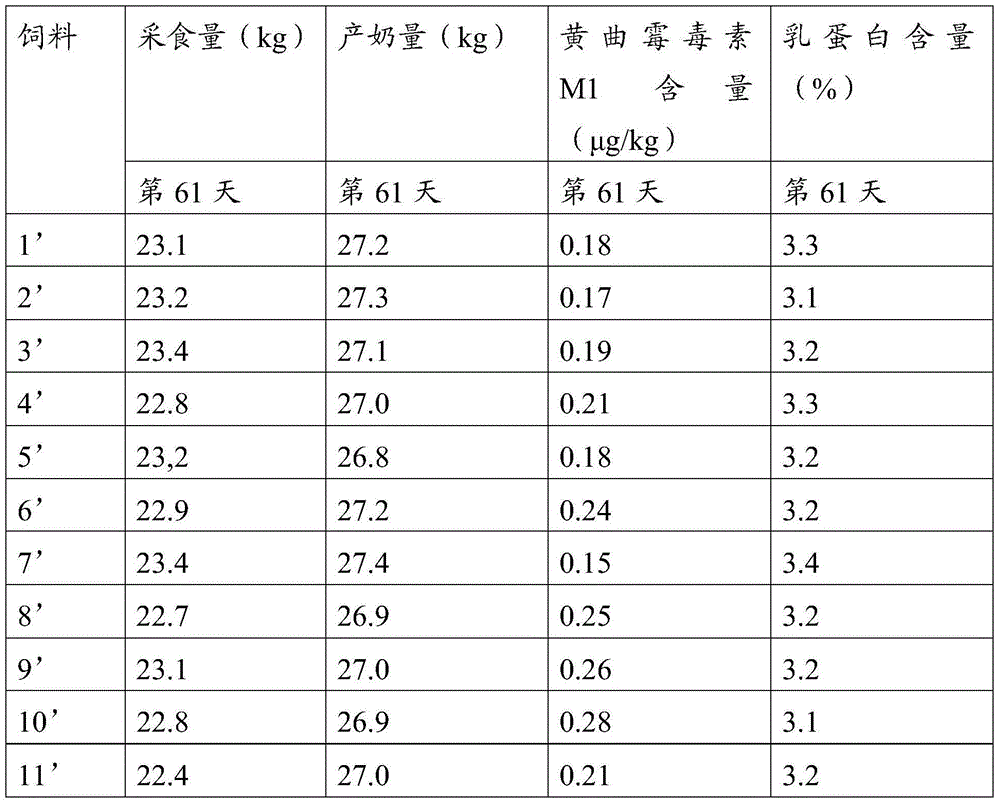

Examples

preparation example Construction

[0067] The preparation method of the feed additive according to the second aspect of the present invention, comprises the following steps:

[0068] a, liquid molasses is mixed with carrier, preferably, liquid molasses and silicon dioxide powder, montmorillonite powder and corncob powder are uniformly mixed step by step;

[0069] b, drying to form a solid feed additive until the mass content of the molasses in the feed additive is 45-55%;

[0070] c, pulverizing the solid feed additive obtained from step b.

[0071] According to the feed using the feed additive according to the third aspect of the present invention, the feed contains the feed additive, and the amount of the feed additive relative to the total mass of the feed for ruminants is 1.5% or less.

[0072] Preferably, the added amount of the feed additive relative to the total mass of feed for ruminants is 1.5%-1.2%.

[0073] After inventing the feed additive, the inventors of the present invention further studied th...

Embodiment 1

[0087] The preparation of embodiment 1 feed additive

[0088] First, weigh 195kg (kilograms) of silica powder, 195kg of montmorillonite powder, 95kg of corncob powder and 480kg of liquid molasses, and then add them in batches to the liquid molasses (divide each raw material into three batches) Silica powder, montmorillonite powder and corn cob powder, so that molasses and silicon dioxide powder, montmorillonite powder and corn cob powder as a carrier are uniformly mixed to obtain a mixture, and the mixture is dried at a temperature of 100° C. for 15 Minutes, a dry block was obtained, and the block was pulverized to obtain feed additive 1#.

Embodiment 2

[0089] The preparation of embodiment 2 feed additives

[0090] First, weigh 205kg of silica powder, 205kg of montmorillonite powder, 105kg of corncob powder and 520kg of liquid molasses, then add silica powder in batches to the liquid molasses (divide each raw material into three batches) , montmorillonite powder and corn cob powder, so that molasses and silicon dioxide powder, montmorillonite powder and corn cob powder as a carrier are evenly mixed to obtain a mixture, and the mixture is dried at a temperature of 110° C. for 12 minutes with a vibrating fluidized bed to obtain The dried block was pulverized to obtain feed additive 2#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com