Apparatus for recovering hydrogen fluoride from hydrofluoric acid

A technology of hydrofluoric acid and hydrogen fluoride, which is applied in the field of machinery, can solve the problems of easy blockage of adsorption tower, easy pulverization of adsorbent, and affecting recovery rate, etc., and achieve the effects of avoiding fluorine pollution, easy analysis, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

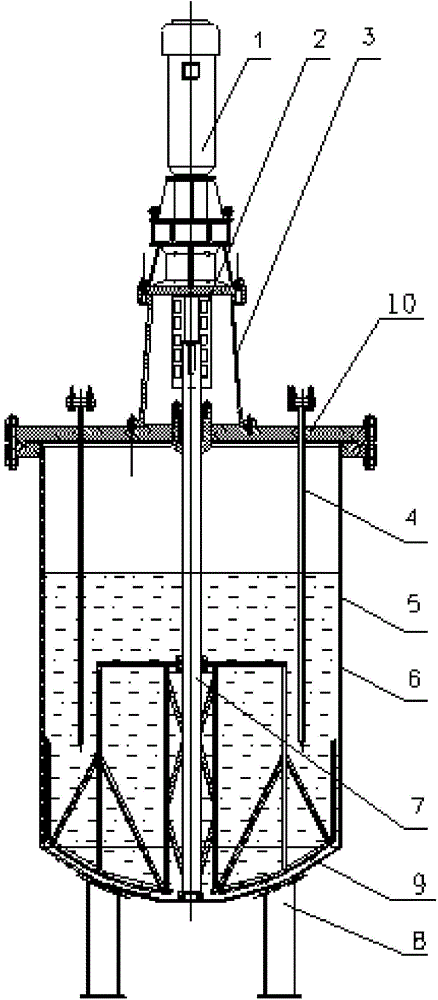

[0015] The structure of the present invention is as figure 1 As shown, a vertical canned structure is adopted, including a motor and a reducer 1, a coupling 2, a frame 3, a thermometer sleeve 4, a cylinder 5, a lining 6, a stirring shaft 7, a bracket 8, a stirring plate 9 and The cylinder cover 10; wherein, the cylinder body 5, the lining 6, the stirrer 7, the stirring plate 9, and the cylinder cover 10 are the main structure of the device, the cylinder body 5 is cylindrical, the bottom is a spherical arc surface, and the lining 6 is placed in the cylinder The lower part of the body 5, whose shape matches the inner wall of the lower part of the cylinder body 5; the cylinder body 5 is sealed and fixed with a cylinder cover 10, the cylinder cover 10 is fixed with a frame 3, and the frame 3 is fixedly installed with a motor and a reducer 1, the motor and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com